Safety Liquid Leak Sensor [Control Category 4 PLe SIL3] SQ4

Download

-

Basic Information

-

Order guide

-

Specifications

-

Dimensions

-

Circuit/ Wiring

-

Cautions For Use

Basic Information

Two-stage detection × Safety certification

CE : Machinery Directive, EMC Directive

UKCA : Machinery Regulations, EMC Regulations

UL, CSA : Certified by TÜV SÜD America Inc.

-

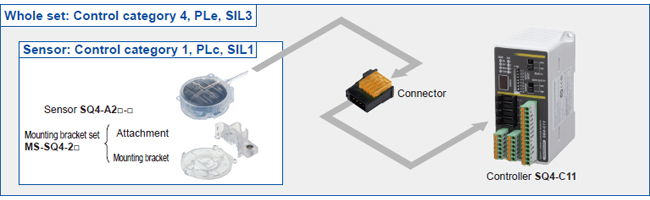

The control category differs depending on the configuration and wiring of the external circuit.

Features

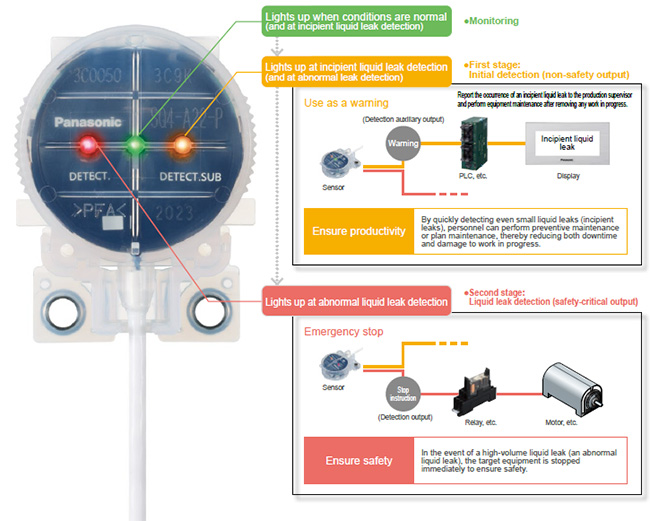

Improved productivity! Two-stage detection

Two-stage detection addresses both incipient liquid leaks (by generating a warning) and abnormal liquid leaks (by initiating an emergency stop).

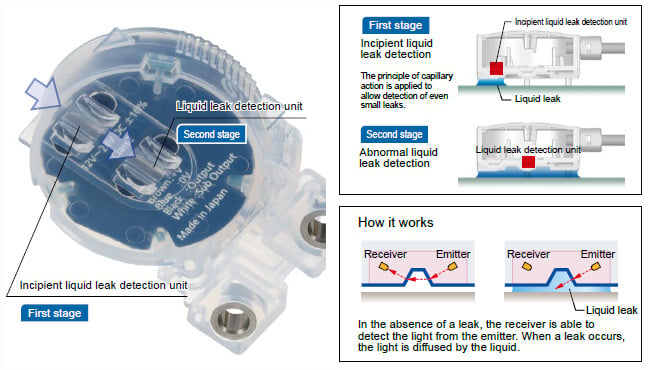

On the bottom of the sensor are two detection units, one located at the front and one at the center. If a liquid leak occurs in front of the sensor, the front detection unit will detect even a small incipient leak. When the leak increases in volume and reaches the center of the sensor, it will be detected as an abnormal leak.

While previous implementations of two-stage liquid leak detection have relied on two separate sensors installed at different heights, the SQ4 delivers the same full-featured detection capability in a single sensor unit.

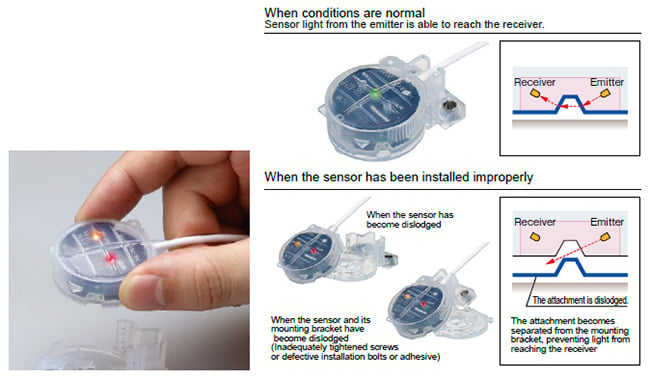

The SQ4 can also detect human error (improper installation).

In addition to detecting liquid leaks, the SQ4 can detect both human error (such as a failure to install the sensor) and sensor malfunctions. If the sensor itself or the sensor and its mounting bracket have become dislodged, have been improperly installed, or are suffering from a broken cable connection, light from the emitter will not reach the receiver, causing the device to generate the same output as if a liquid leak had occurred.

Knurling on the sides of the sensor head makes it easy to grip.

The SQ4 can also be used alone.

The SQ4 can also be used without a controller, allowing the benefits of two-stage detection to be added to existing equipment by augmenting or replacing existing detection systems.

Acquire safety certification.

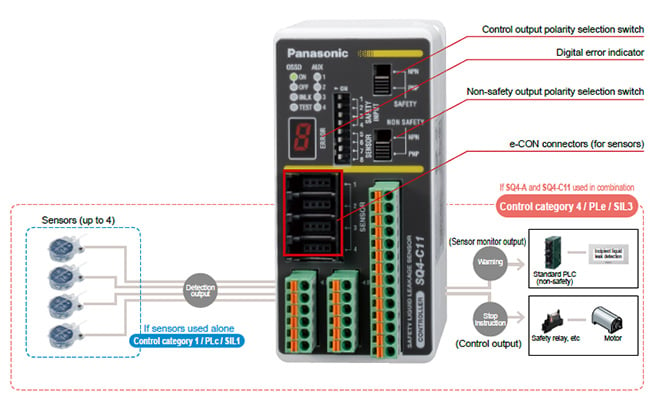

The SQ4 delivers safety performance of the highest caliber.

The SQ4 system is designed to fulfill safety requirements imposed by international standards. When used in combination, the SQ4-A sensor and SQ4-C11 controller meet category 4 / PLe / SIL3 requirements under ISO 13849-1, which has been updated to add probability criteria to the existing risk evaluation system (in the control category), allowing the functional safety of programmable electronic control systems and related devices to be evaluated. The sensor fulfills control category 1 / PLc / SIL1 requirements when used in a standalone configuration.

*As of October 2010; according to research by Panasonic Industry.

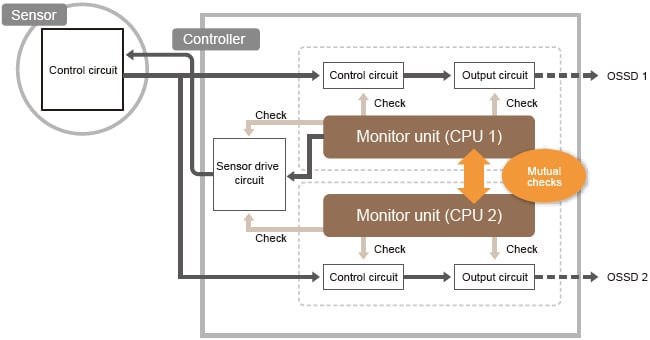

Dual CPUs deliver an advanced level of safety control.

The controller's two independent CPUs mutually check the unit's operating state, and redundant signal processing and output circuits ensure safety.

Failure mode and effects analysis (FMEA)* further increases operational safety.

* FMEA comprises a systematic method for analyzing latent failures and defects so that they can be prevented from manifesting themselves.

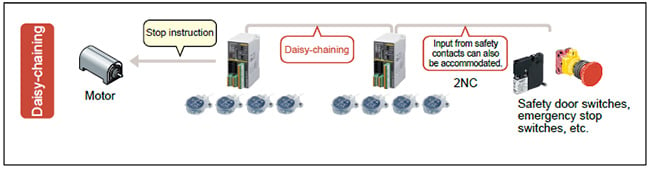

Reduce wiring and lower costs by daisy-chaining controllers and other safety equipment.

The controller's safety input function can be used to connect wiring used to daisy-chain controllers together as well as input from safety contacts (2NC) on emergency stop switches, safety door switches, and other devices. In this way, safety output can be aggregated onto a single line to reduce safety circuit wiring and lower costs.

*Systems that connect two or more safety contacts on door switches or other devices fall under control category 3.

*The response times for all connected devices are added together to obtain the system response time.

Order guide

Product Configuration

Sensors

| Type | Appearance | Sensing object (Note 1) | Model No. | Output |

|---|---|---|---|---|

| For standard liquid |  Material:Polypropylene | Water etc. | SQ4-A21-P | PNP open-collector transistor |

| SQ4-A21-N | NPN open-collector transistor | |||

| For chemical liquid |  Material:PFA | Sulfuric acid, Hydrochloric acid, Phosphoric acid, Ammonia, Fluorinert™ (Note 2), Galden® (Note 2) or Fluorine etc. | SQ4-A22-P | PNP open-collector transistor |

| SQ4-A22-N | NPN open-collector transistor |

(Note 1) The agents mentioned above are examples. It may not be detected depending on viscosity the agent. Before using this device, check the detecting liquid and installation condition.

(Note 2) Fluorinert is the world wide trademark of 3M. Galden is the registered trademark of Solvay.

Mounting bracket set

Make sure to purchase the sensor and controller as a set.

| Type | Appearance | Sensing object | Model No. | |

|---|---|---|---|---|

| Attachment | Mounting bracket | |||

| For standard liquid |  Material:Polypropylene |  Material: PVC | Water etc. | MS-SQ4-21 |

| For chemical liquid |  Material: PFA |  Material: PFA | Liquids with comparatively high surface tension such as Sulfuric acid, Hydrochloric acid, Phosphoric acid, and Ammonia | MS-SQ4-22 |

Material: PVC | Liquids with comparatively low surface tension such as Fluorinert™ (Note), Galden® (Note), and Hydrogen fluoride | MS-SQ4-23 | ||

| Liquids such as low-concentration hydrogen fluoride | MS-SQ4-24 | |||

(Note) Fluorinert is the world wide trademark of 3M. Galden is the registered trademark of Solvay.

Connectors

Make sure to purchase the connector when using the controller.

| Designation | Model No. | Description |

|---|---|---|

| Hook-up connector (e-CON) | CN-EP2 | For SQ4-A21-□ (PVC cable) It is used to connect to the controller. Yellow (5 pcs. per set) |

| CN-EP3 | For SQ4-A22-□ (PFA cable) It is used to connect to the controller. Orange (5 pcs. per set) |

Hook-up connector

CN-EP2

CN-EP3

Controller

| Type | Appearance | Model No. | Description |

|---|---|---|---|

| Safety controller |  | SQ4-C11 | Up to 4 safety liquid leak sensors can be connected. Control Category 4, PLe, SIL3 |

Specifications

Sensors

| Type | For standard liquid | For chemical liquid | |

|---|---|---|---|

| Model No. | PNP output | SQ4-A21-P | SQ4-A22-P |

| NPN output | SQ4-A21-N | SQ4-A22-N | |

| Sensing object(Note 2) | Water (Standard liquid) (Note 3) | Sulfuric acid, Hydrochloric acid, Phosphoric acid, Ammonia, Fluorinert™ (Note 4), Galden® (Note 4), Hydrofluoric acid etc. (Note 3) | |

| Supply voltage | 12 to 24 V DC ±10 % Ripple P-P 10 % or less | ||

| Current consumption | 30 mA or less | ||

| Utilization category | DC-12, DC-13 | ||

| Detection output (Leakage detection) | <PNP output type> PNP open-collector transistor • Maximum source current: 50 mA • Applied voltage: Same as the supply voltage (between detection output and +V) • Residual voltage: 2.5 V or less (at 50 mA source current) <NPN output type> NPN open-collector transistor • Maximum sink current: 50 mA • Applied voltage: Same as the supply voltage (between detection output and 0 V) • Residual voltage: 2 V or less (at 50 mA sink current) | ||

| Response time | 10 ms or less | ||

| Output operation | ON when normal condition or initial detection, OFF when detection leakage or wrong installation | ||

| Short-circuit protection | Incorporated | ||

| Detection auxiliary output (Initial detection) | <PNP output type> PNP open-collector transistor • Maximum source current: 50 mA • Applied voltage: Same as the supply voltage (between detection auxiliary output and +V) • Residual voltage: 2.5 V or less (at 50 mA source current) <NPN output type> NPN open-collector transistor • Maximum sink current: 50 mA • Applied voltage: Same as the supply voltage (between detection auxiliary output and 0 V) • Residual voltage: 2 V or less (at 50 mA sink current) | ||

| Response time | 50 ms or less | ||

| Output operation | ON when normal condition, OFF when initial detection or accidental leakage | ||

| Short-circuit protection | Incorporated | ||

| Protection | IP65 / IP67 (IEC) | ||

| Ambient temperature | -10 to +55 ℃ +14 to +131 ℉ (No dew condensation or icing allowed) (Note 5) Storage: -10 to +55 ℃ +14 to +131 ℉ | ||

| Ambient humidity | 35 to 85 % RH, Storage: 35 to 85 % RH | ||

| Emitting element | Infrared LED (modulated) | ||

| Material | Enclosure: Polypropylene | Enclosure: PFA | |

| Cable | 0.18 mm2 4-core PVC cabtyre cable, 2 m 6.562 ft long | 0.1 mm2 4-core PFA cabtyre cable, 2 m 6.562 ft long | |

| Weight | Net weight: 45 g approx., Gross weight: 110 g approx. | ||

Notes:

1) Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +20 ℃ +68 ℉.

2) Highly viscous liquid may not be stably detected.

3) The agents mentioned above are examples. It may not be detected depending on viscosity the agent.

Before using this device, check the detecting liquid and installation condition.

4) Fluorinert is the world wide trademark of 3M. Galden is the registered trademark of Solvay.

5) Liquid being detected should be also kept within the rated ambient temperature range.

Controller

| Model No. | SQ4-C11 | |

|---|---|---|

| Applicable standards | International standard | ISO 13849-1 (Category 4, PLe), IEC 61508-1 to 3 (SIL3) |

| Japan | JIS B 9705-1 (Category 4), JIS C 0508-1 to 3 (SIL3) | |

| Europe (Note 2) | EN 55011 Class A, EN 61000-6-2, EN 50178, EN ISO 13849-1 (Category 4, PLe), EN 61508-1 to 3 (SIL3) | |

| North America (Note 3) | ANSI/UL 508, CAN/CSA C22.2 No.14 | |

| South Korea | S1-G-1, S2-W-5, KS C IEC 60947-5-2 | |

| SEMI | Conforming to SEMI-S2-0310a | |

| Power voltage | 24 V DC+10-15 % Ripple P-P 10 % or less | |

| Consumption current | 200 mA or less | |

| Control output [OSSD 1(Y1), OSSD 2(Y2)] | PNP open-collector transistor / NPN open-collector transistor (switch method) <Selecting PNP output> • Maximum source current: 200 mA • Applied voltage: Same as power voltage (between control output to +V) • Residual voltage: 2.5 V or less (at 200 mA source current) <Selecting NPN output> • Maximum sink current: 200 mA • Applied voltage: Same as power voltage (between control output to 0 V) • Residual voltage: 2.0 V or less (at 200 mA sink current) | |

| Response time | 20 ms or less (excluding the response time of the sensor) | |

| Operation mode (Output operation) | ON when normal condition or initial detection, OFF when detection leakage or wrong installation | |

| Protection circuit (Short-circuit protection) | Incorporated | |

| Utilization category | DC-12, DC-13 | |

| Sensor monitor output (AUX1, 2, 3, 4, Non-safety output) | PNP open-collector transistor / NPN open-collector transistor (switch method) <Selecting PNP output> • Maximum source current: 60 mA • Applied voltage: Same as power voltage(between sensor monitor output to +V) • Residual voltage: 2.5 V or less (at 60 mA source current) <Selecting NPN output> • Maximum sink current: 60 m A • Applied voltage: Same as power voltage(between sensor monitor output to 0 V) • Residual voltage: 2.0 V or less (at 60 mA sink current) | |

| Response time | 100 ms or less (excluding the response time of the sensor) | |

| Operation mode (Output operation) | ON when normal condition, OFF when initial detection or accidental leakage | |

| Protection circuit (Short-circuit protection) | Incorporated | |

| Utilization category | DC-12, DC-13 | |

| Lockout output | OFF for lockout (Rating: Same as sensor monitor output) | |

| Auxiliary output | Negative logic output of control output 1 / 2 (OSSD 1 / 2) (Rating: Same as sensor monitor output) [Auxiliary output ON when control output 1 / 2 (OSSD 1/2) is OFF] | |

| Functions | Interlock / lockout cancel / Test input / External device monitor / Safety input / Control output polarity selection / Non-safety output polarity selection / Sensor connection number setting | |

| Protection | IP20 (IEC) (However, it should be in IP54 protection structure of control panel) | |

| Ambient temperature | -10 to +55 ℃ +14 to +131 ℉ (No dew condensation or icing allowed), Storage: -20 to +70 ℃ -4 to +158 ℉ | |

| Ambient humidity | 35 to 85 % RH, Storage: 35 to 85 % RH | |

| PFH | When PNP output is selected: 1.89 × 10-9 (when connecting 4 safety liquid leak sensors) When NPN output is selected: 1.80 × 10-9 (when connecting 4 safety liquid leak sensors) | |

| MTTFD | Selecting PNP output: 511 years (when connecting 4 safety liquid connecting sensors) Selecting NPN output: 532 years (when connecting 4 safety liquid connecting sensors) | |

| Material | Main unit case: PC+ABS (alloy) | |

| Weight | Net weight: 170 g approx., Gross weight: 440 g approx. | |

Notes:

1) Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +20 ℃ +68 ℉.

PFH: Probability of dangerous failure per hour, MTTFD: Mean time to dangerous failure (in years)

2) Regarding EU Machinery Directive, a Notified Body, TÜV SÜD, has certified with the type examination certificate.

3) With regards to the standards in US / Canada, a Notified Body, TÜV SÜD, has certified the cTÜVus mark.

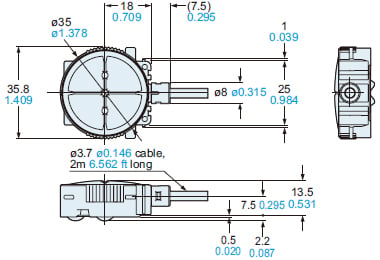

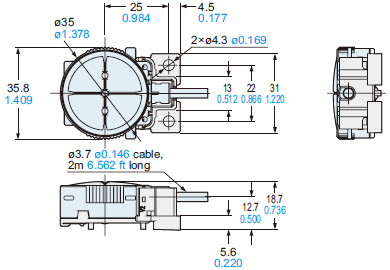

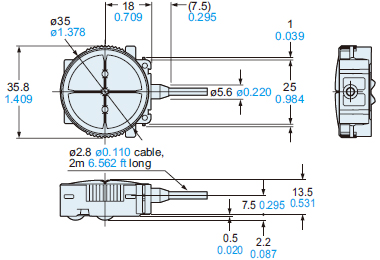

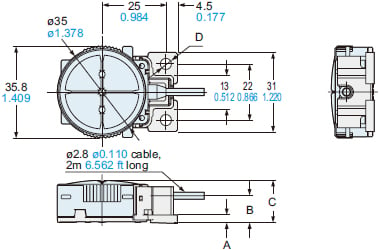

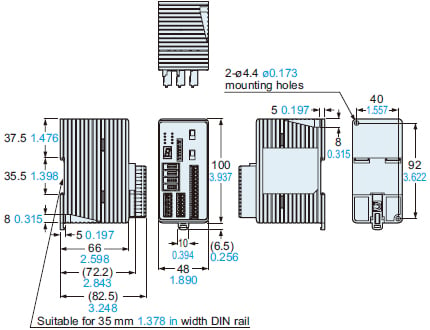

Dimensions

- Unit: mm in

SQ4-A21-□

Sensor

Assembly dimensions with mounting bracket for MS-SQ4-21

SQ4-A22-□

Sensor

Assembly dimensions with mounting bracket

| Mounting bracket set model No. | A | B | C | D |

|---|---|---|---|---|

| MS-SQ4-22 | 5.4 0.213 | 12.7 0.500 | 18.7 0.736 | 2×ø4.2 ø0.165 |

| MS-SQ4-23 | 3.4 0.134 | 10.5 0.413 | 16.5 0.650 | 2×ø4.3 ø0.169 |

| MS-SQ4-24 | 5.6 0.220 | 12.7 0.500 | 18.7 0.736 | 2×ø4.3 ø0.169 |

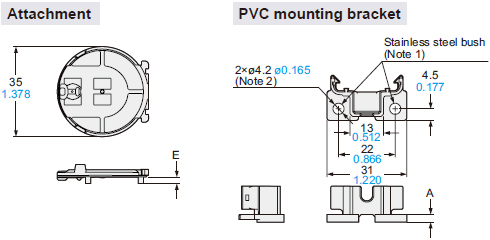

MS-SQ4-□

Mounting bracket set

| Mounting bracket set model No. | A | E |

|---|---|---|

| MS-SQ4-21 | 5.6 0.220 | 2.5 0.098 |

| MS-SQ4-22 | 5.4 0.213 | 2.5 0.098 |

| MS-SQ4-23 | 3.4 0.134 | 0.3 0.012 |

| MS-SQ4-24 | 5.6 0.220 | 2.5 0.098 |

Notes:

1) Drawing above is for PFA mounting bracket.

PVC mounting brackets do not incorporate stainless steel bushes.

2) The size of mounting holes of PVC mounting bracket is ø4.3 mm ø0.169 in

SQ4-C11

Controller

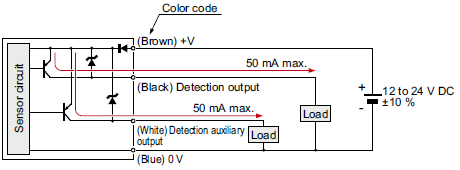

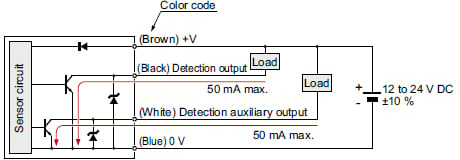

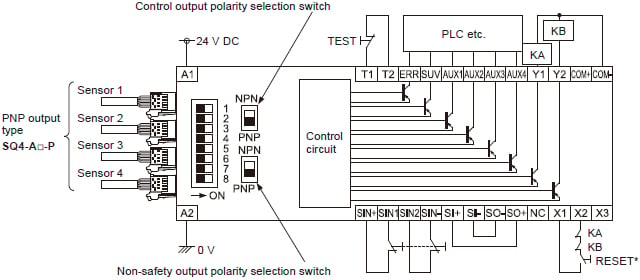

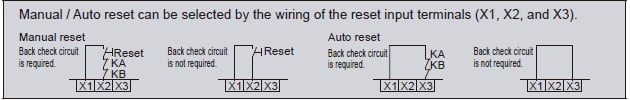

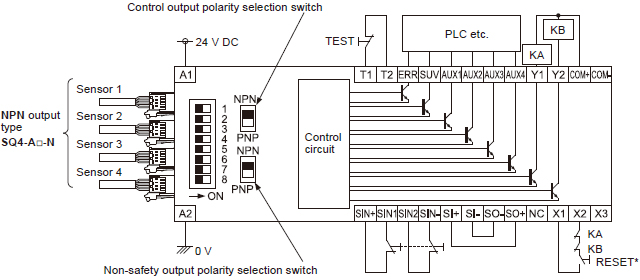

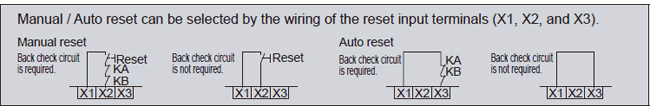

I/O Circuit and Wiring diagrams

Sensors

SQ4-A□-P

[PNP output type]

SQ4-A□-N

[NPN output type]

Controller

SQ4-C11

For operation with PNP output

KA, KB: External devices(Forced guide relay, magnet contactor or monitored valve)

*RESET

For operation with NPN output

KA, KB: External devices(Forced guide relay, magnet contactor or monitored valve)

*RESET

Cautions For Use

- This product is a sensor for detecting leak of fluids.

- When this product is used with safety devices, construct the system such that the device itself.

- Before using this device, check whether the device performs properly with the functions and capabilities as per the design specifications.

- Avoid using this device in an explosive atmosphere because this product does not have an explosive-proof protective construction.

Installation

- There is the detection mount difference by directivity of a liquid leakage. When there are a direction from which a liquid leakage happens, and an inclination, please install the nose-of-cam side (opposite side of a cable) of a sensor towards a top.

- Use the mounting bracket MS-SQ4-□ (optional) which suits the liquid to detect.

- Periodical checking of operation is recommended with the liquids which are not dangerous (water, alcohol, etc.).

- The amount of detection may change with the conditions of the installation surface.

- Be sure to use the mounting bracket MS-SQ4-□ (optional) when installing this device to avoid human error, etc.

Reliable detection cannot be guaranteed when this sensor is used alone.

Maintenance

- Before conduct maintenance, be sure that the system is in safety state.

- When using chemical liquid, use proper protections such as groves, masks, goggles, helmets etc. When using protections, be sure to read manuals of them and use properly.

- Dispose or reinstall in different environment, flush with DI water.

Mounting

- Keep enough space for maintenance when mounting this product.

Leakage detection condition and variation factor

- Leak detection part of this product properly detects the leakage in the following condition.

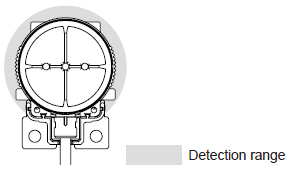

1. Detection range: Area except backward of this product (liquid must enter to the detection range)

2. Material of installation surface: Hard vinyl chloride or Stainless steel

3. Surface condition for installation: Glossy surface (surface roughness: corresponding 0.4 μmRa) and clean surface.

4. Installation surface angle: Horizontal

- This product may not detect properly liquid in following element.

1. Liquid kind, consistency (surface tension) and air bubble incorporation.

2. Material, roughness, angle, dirtiness and liquid absorption of surface of installed surface of sensor.

3. Wrong selection of dedicated mounting bracket.

- Check the detecting liquid and the installation condition before use.