MINAS A5 Family (Discontinued Products)

Download

-

Discontinued Products

-

Lineup

-

System Configuration

-

Specifications

-

Dimensions

-

Wiring/ Connection

-

Option

-

Software

Ⅾiscontinued

Last time buy (JST)

July 31, 2022

Discontinued Products

Recommended Substitutes

Lineup

Motor Lineup

Low inertia

| Motor | Voltage | Rated output (kW) | Rated rotational speed (Max. speed) (r/min) | Rotary encoder | Enclosure (*1) | Features | |

|---|---|---|---|---|---|---|---|

| 20-bit incremental | 17-bit/ absolute | ||||||

MSMJ | 200 V | 0.2 0.4 | 3000 | ○ | ○ | IP65 | - |

| 0.75 | 3000 (4500) | ||||||

MSMD | 100 V | 0.05 0.1 | 3000 | ○ | ○ | IP65 | • Leadwire type • Small capacity • Suitable for high speed application • Suitable for all applications |

| 200 V | 0.75 | 3000 | |||||

MSME | 100 V 200 V | 0.05 0.1 0.2 0.4 | 3000 (6000) | ○ | ○ | IP67 | • Small capacity • Suitable for high speed application • Suitable for all applications |

| 200 V | 0.75 | ||||||

MSME | 400 V | 0.75 | 3000 | ○ | ○ | IP65(*2) | • Middle capacity • Suitable for the machines directly coupled with ball screw and high stiffness and high repetitive application |

| 200 V 400 V | 1.0 1.5 2.0 3.0 | ||||||

| 4.0 5.0 | 3000 (4500) | ||||||

Middle inertia

| Motor | Voltage | Rated output (kW) | Rated rotational speed (Max. speed) (r/min) | Rotary encoder | Enclosure (*1) | Features | |

|---|---|---|---|---|---|---|---|

| 20-bit incremental | 17-bit/ absolute | ||||||

MDME | 400 V | 0.4 0.6 | 2000 | ○ | ○ | IP65(*2) | • Middle capacity • Suitable for low stiffness machines with belt driven |

| 200 V 400 V | 1.0 1.5 2.0 3.0 4.0 5.0 | ||||||

| 7.5(*3) | 1500 (3000) | ||||||

| 11.0(*3) 15.0(*3) | 1500 (2000) | ||||||

| MFME (Flat type) (*3)  | 200 V 400 V | 1.5 2.5 4.5 | 2000 (3000) | ○ | ○ | IP67 | • Middle capacity • Flat type and suitable for machines with space limitation |

| MGME (Low speed/ High torque type)  | 200 V 400 V | 0.9 2.0 3.0 4.5(*3) 6.0(*3) | 1000 (2000) | ○ | ○ | IP65(*2) | • Middle capacity • Suitable for low speed and high torque application |

High inertia

| Motor | Voltage | Rated output (kW) | Rated rotational speed (Max. speed) (r/min) | Rotary encoder | Enclosure (*1) | Features | |

|---|---|---|---|---|---|---|---|

| 20-bit incremental | 17-bit/ absolute | ||||||

MHMD | 100 V 200 V | 0.2 | 3000 | ○ | ○ | IP65 | • Leadwire type • Small capacity • Suitable for low stiffness machines with belt driven |

| 200 V | 0.75 | 3000 (4500) | |||||

MHME | 200 V 400 V | 1.0 1.5 | 2000 | ○ | ○ | IP65(*2) | • Middle capacity • Suitable for low stiffness machines with belt driven,and large load moment of inertia |

| 7.5(*3) | 1500 (3000) | ||||||

(*1)Except for output shaft, and connector.

(*2)IP67 motor is also available.

(*3)Only IP67 motor is avilable.

Driver Lineup

| Series | Control method | Interface/ Communication function | Safety Function |

|---|---|---|---|

A5 Series | Position control, Velocity control, Torque control, | Analog/Pulse input, Modbus (RS485 /RS232) | with |

A5Ⅱ Series | Position control, Velocity control, Torque control, | Analog/Pulse input, Modbus (RS485 /RS232) | with |

A5E Series | Position control | Pulse input | without |

A5ⅡE Series | Position control, 2DOF settings | Pulse input | without |

System Configuration

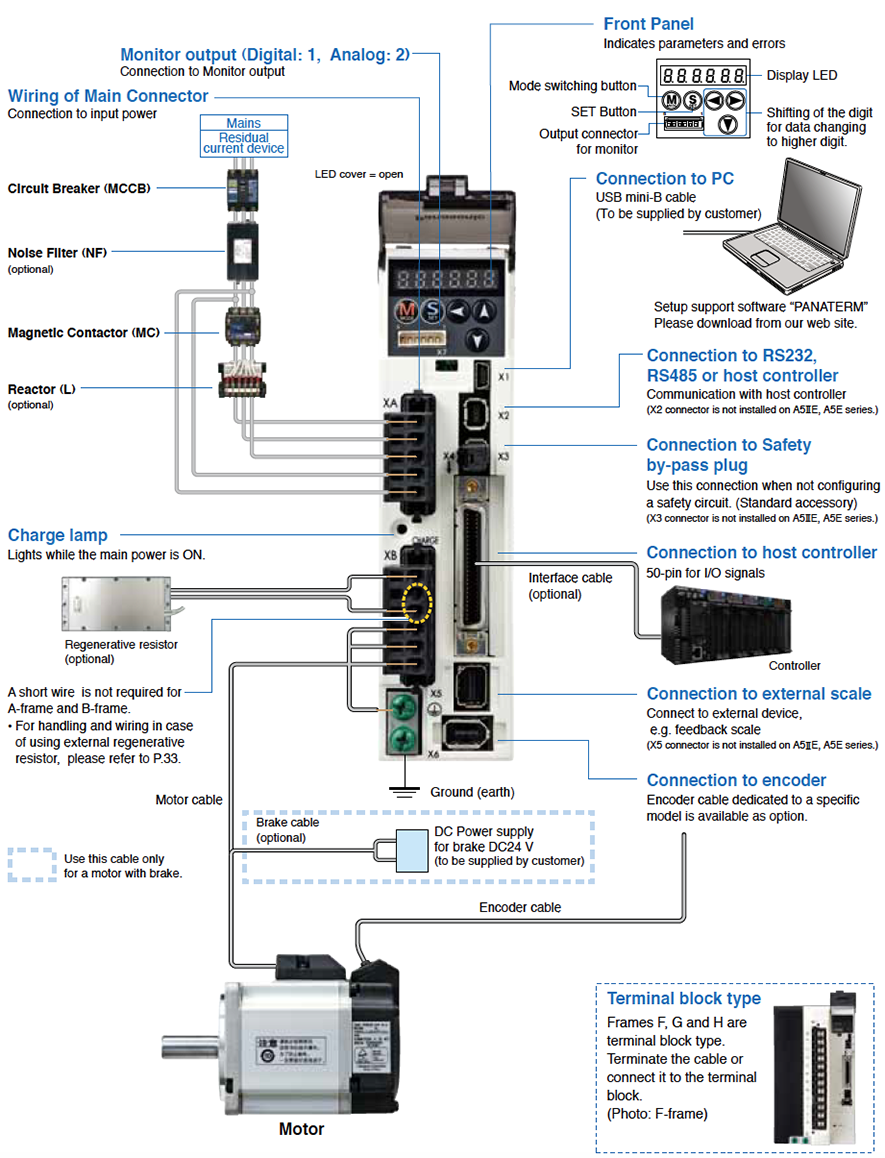

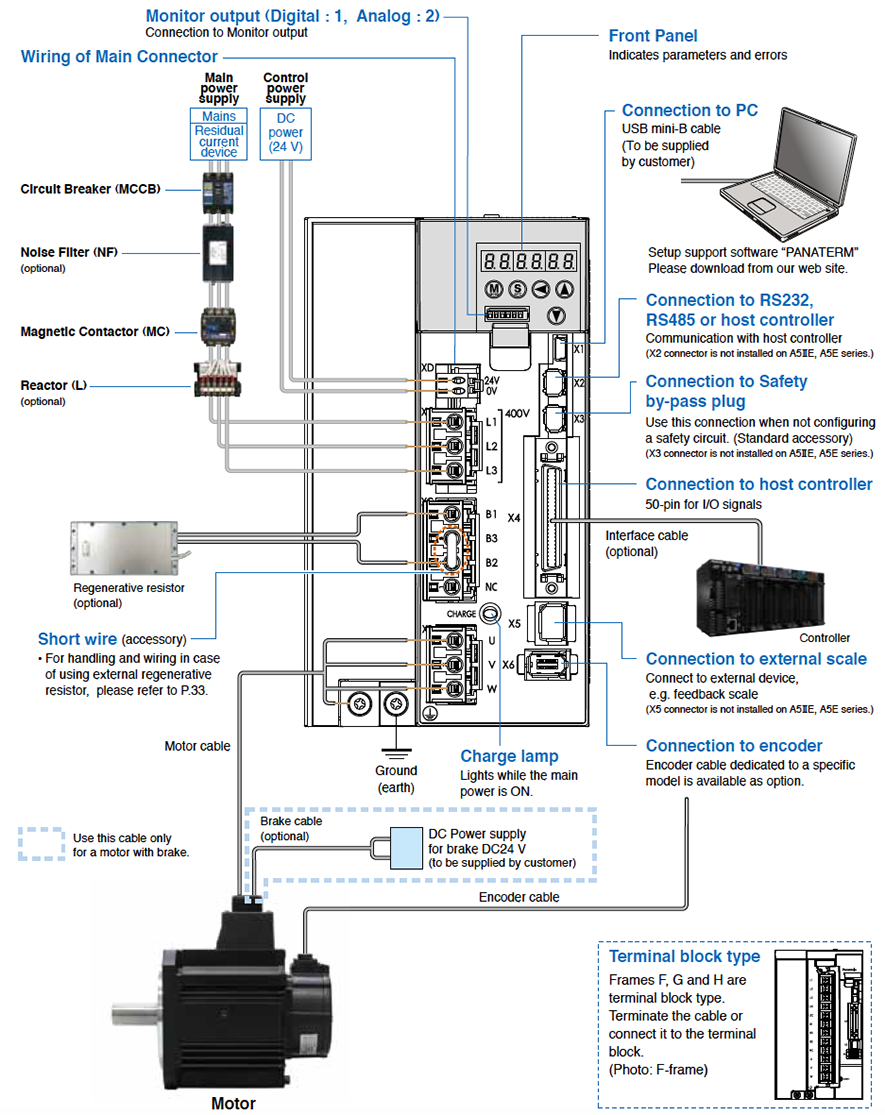

Overall Wiring

[Connector type (100/200 V: A-frame to E-frame)]

Caution

Apply adequate tightening torque to the product mounting screw by taking into consideration strength of the screw and the characteristics of material to which the product is installed. Overtightening can damage the screw and/or material; undertightening can result in loosening.

Example) Steel screw (M5) into steel section: 2.7 N·m to 3.3 N·m.

[Connector type (400 V: D, E-frame)]

Note

Initial setup of rotational direction: positive = CCW and negative = CW. Pay an extra attention.

Driver and List of Applicable Peripheral Equipments

| Driver | Applicable motor | Voltage *1 | Rated output | Required Power (at the rated load) | Circuit breaker (rated current) | Noise filter (Single phase/ 3-phase) | Surge absorber (Single phase/3-phase) | Noise filter for signal | Rated operating current of magnetic (contactor Contact configuration)*2 | Diameter and withstand voltage of main circuit cable | Crimp terminal for main circuit terminal block *4 | Diameter and withstand voltage of control power supply cable | Crimp terminal for control power supply terminal block | Diameter and withstand voltage of motor cable *5 | Diameter and withstand voltage of brake cable |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MADH MADK | MSMD MSME MHMD | Single phase, 100 V | 50 W to 100 W | approx. 0.4 kVA | 10 A | DV0P4170 | DV0P4190 | DV0P1460 | 20 A (3P+1a) | 0.75 mm2/ AWG18 600 VAC or more | Connection to exclusive connector | 0.75 mm2/ AWG18 600 VAC or more | Connection to exclusive connector | 0.75 mm2/ AWG18 600 VAC or more | 0.28 mm2 to 0.75 mm2/ AWG22 to AWG18 100 VAC or more |

| Single/ 3-phase, 200 V | 50 W to 200 W | approx. 0.5 kVA | DV0P4170/ DV0PM20042 | DV0P4190/ DV0P1450 | |||||||||||

| MBDH MBDK | MSMD MSME MHMD | Single 100 V | 200 W | approx. 0.5 kVA | DV0P4170 | DV0P4190 | |||||||||

| Single/ 3-phase, 200 V | 400 W | approx. 0.9 kVA | DV0P4170/ DV0PM20042 | DV0P4190/ DV0P1450 | |||||||||||

| MCDH MCDK | MSMD MSME MHMD | Single 100 V | 400 W | approx. 0.9 kVA | DV0PM20042 | DV0P4190 | |||||||||

| Single/ 3-phase, 200 V | 750 W | approx. 1.3 kVA | 15 A | DV0P4190/ DV0P1450 | |||||||||||

| MDDH MDDK | MDME | Single/ 3-phase, 200 V | 1.0 kW | approx. 1.8 kVA | DV0P4220 | 30 A (3P+1a) | 2.0 mm2/ AWG14 600 VAC or more | 2.0 mm2/ AWG14 600 VAC or more | 0.75 mm2/ AWG18 100 VAC or more | ||||||

| MHME | |||||||||||||||

| MGME | 0.9 kW | approx. 1.8 kVA | 20 A | ||||||||||||

| MSME | 1.0 kW | approx. 1.8 kVA | |||||||||||||

| MHME | 1.5 kW | approx. 2.3 kVA | |||||||||||||

| MDME | |||||||||||||||

| MFME | |||||||||||||||

| MSME | |||||||||||||||

| MDME | 3-phase, 400 V | 400 W | approx. 0.9 kVA | 10 A | FN258L-16-07 (Recommended component ) | DV0PM20050 | 20 A (3P+1a) | 0.52 mm2/ AWG20 100 VAC or more | |||||||

| MDME | 600 W | approx. 1.2 kVA | |||||||||||||

| MSME | 750 W | approx. 1.6 kVA | |||||||||||||

| MSME | 1.0 kW | approx. 1.8 kVA | |||||||||||||

| MDME | |||||||||||||||

| MHME | |||||||||||||||

| MGME | 0.9 kW | ||||||||||||||

| MSME | 1.5 kW | approx. 2.3 kVA | |||||||||||||

| MDME | |||||||||||||||

| MFME | |||||||||||||||

| MHME | |||||||||||||||

| MEDH MEDK | MDME | 3-phase, 200 V | 2.0 kW | approx. 3.3 kVA | 30 A | DV0PM20043 | DV0P1450 | DV0P1460 RJ8035 (Recommended component ) *6 | 60 A (3P+1a) | 0.75 mm2/ AWG18 600 VAC or more | |||||

| MSME | |||||||||||||||

| MHME | |||||||||||||||

| MFME | 2.5 kW | approx. 3.8 kVA | |||||||||||||

| MSME | 3-phase, 400 V | 2.0 kW | approx. 3.3 kVA | 15 A | FN258L-16-07 (Recommended component ) | DV0PM20050 | DV0P1460 | 30 A (3P+1a) | 0.52 mm2/ AWG20 100 VAC or more | ||||||

| MDME | |||||||||||||||

| MHME | |||||||||||||||

| MFME | 2.5 kW | approx. 3.8 kVA | |||||||||||||

| MFDH MFDK | MGME | 3-phase, 200 V | 2.0 kW | approx. 3.8 kVA | 50 A | DV0P3410 | DV0P1450 | DV0P1460 RJ8035 (Recommended component ) *6 | 60 A (3P+1a) | 3.5 mm2/ AWG12 600 VAC or more |

Terminal block M5 | 0.75 mm2/ AWG18 600 VAC or more |

Terminal block M5 | 3.5 mm2/ AWG12 600 VAC or more | |

| MDME | 3.0 kW | approx. 4.5 kVA | |||||||||||||

| MHME | |||||||||||||||

| MSME | |||||||||||||||

| MGME | |||||||||||||||

| MDME | 4.0 kW | approx. 6.0 kVA | 100 A (3P+1a) | ||||||||||||

| MHME | |||||||||||||||

| MSME | |||||||||||||||

| MFME | 4.5 kW | approx. 6.8 kVA | |||||||||||||

| MGME | approx. 7.5 kVA | ||||||||||||||

| MDME | 5.0 kW | ||||||||||||||

| MHME | |||||||||||||||

| MSME | |||||||||||||||

| MGME | 3-phase, 400 V | 2.0 kW | approx. 3.8 kVA | 30 A | FN258L-30-07 (Recommended component ) | DV0PM20050 | DV0P1460 | 60 A (3P+1a) |

Terminal block M4 | 0.75 mm2/ AWG18 100 VAC or more |

Terminal block M3 | ||||

| MSME | 3.0 kW | approx. 4.5 kVA | |||||||||||||

| MDME | |||||||||||||||

| MGME | |||||||||||||||

| MHME | |||||||||||||||

| MSME | 4.0 kW | approx. 6.0 kVA | |||||||||||||

| MDME | |||||||||||||||

| MHME | |||||||||||||||

| MFME | 4.5 kW | approx. 6.8 kVA | |||||||||||||

| MGME | approx. 7.5 kVA | ||||||||||||||

| MSME | 5.0 kW | ||||||||||||||

| MDME | |||||||||||||||

| MHME | |||||||||||||||

| MGDH MGDK | MDME | 3-phase, 200 V | 7.5 kW | approx. 11 kVA | 60 A | FS5559-60-34 (Recommended component ) | DV0P1450 | DV0P1460 RJ8095 Recommended ( component ) T400-61D (Recommended component ) *6 | 100 A (3P+1a) | 5.3 mm2/ AWG10 600 VAC or more |

Terminal block M5 | 0.75 mm2/ AWG18 600 VAC or more |

Terminal block M5 | 13.3 mm2/ AWG6 600 VAC or more | |

| MGME | 6.0 kW | approx. 9.0 kVA | |||||||||||||

| MHME | 7.5 kW | approx. 11 kVA | |||||||||||||

| MDME | 3-phase, 400 V | 7.5 kW | approx. 11 kVA | 30 A | FN258-42-07 or FN258-42-33 (Recommended component ) | DV0PM20050 | 60 A (3P+1a) | 0.75 mm2/ AWG18 100 VAC or more | |||||||

| MGME | 6.0 kW | approx. 9.0 kVA | |||||||||||||

| MHME | 7.5 kW | approx. 11 kVA | |||||||||||||

| MHDH MHDK | MDME | 3-phase, 200 V | 11 kW | approx. 17 kVA | 100 A | FS5559-80-34 (Recommended component ) | DV0P1450 | 150 A (3P+1a) | 13.3 mm2/ AWG6 600 VAC or more *3 |

Terminal block M6 | 0.75 mm2/ AWG18 600 VAC or more |

Terminal block M4 | |||

| 15 kW | approx. 22 kVA | 125 A | 21.1 mm2/ AWG4 600 VAC or more | ||||||||||||

| 3-phase, 400 V | 11 kW | approx. 17 kVA | 50 A | FN258-42-07 or FN258-42-33 (Recommended component ) | DV0PM20050 | 100 A (3P+1a) | 0.75 mm2/ AWG18 100 VAC or more | 13.3 mm2/ AWG6 600 VAC or more | |||||||

| 15 kW | approx. 22 kVA | 60 A | 21.1 mm2/ AWG4 600 VAC or more |

*1 Select peripheral equipments for single/3phase common specification according to the power source.

*2 For the external dynamic brake resistor, use the magnetic contactor with the same rating as that for the main circuit.

*3 When use the external regenerative resistor of the option (DV0PM20058, DV0PM20059), use the cable with the same diameter as the main circuit cable.

*4 For the ground screw, use the same crimp terminal as that for the main circuit terminal block.

*5 The diameter of the ground cable and the external dynamic brake resistor cable must be equal to, or larger than that of the motor cable.

The motor cable is a shield cable, which conforms to the EC Directives and UL Standards. (G, H-frame only)

*6 Use thses products to suit an international standard.

●About circuit breaker and magnetic contactor

To comply to EC Directives, install a circuit breaker between the power and the noise filter without fail, and the circuit breaker should conform to IEC Standards and UL recognized (Listed and ![]() marked).

marked).

Suitable for use on a circuit capable of delivering not more than 5000 Arms symmetrical amperes, below the maximum input voltage of the product.

If the short-circuit current of the power supply exceeds this value, install a current limit device (current limiting fuse, current limiting circuit breaker, transformer, etc.) to limit the short-circuit current.

<Remarks>

- Select a circuit breaker and noise filter which match to the capacity of power supply (including a load condition).

● Terminal block and protective earth terminals

- Use a copper conductor cables with temperature rating of 75 ℃ or higher.

- Use the attached exclusive connector for A-frame to E-frame, and maintain the peeled off length of 8 mm to 9 mm.

■Fastening torque list (Terminal block screw/Terminal cover fastening screw)

| Driver | Terminal block screw | Terminal cover fastening screw | |||

|---|---|---|---|---|---|

| Frame | Terminal name | Nominal size | Fastening torque (N・m) | Nominal size | Fastening torque (N・m) |

| F(200 V) | L1, L2, L3, L1C, L2C, B1, B2, B3, NC, U, V, W | M5 | 1.0 to 1.7 | M3 | 0.19 to 0.21 |

| F(400 V) | 24V、0V | M3 | 0.4 to 0.6 | ||

| L1, L2, L3, B1, B2, B3, NC, U, V, W | M4 | 0.7 to 1.0 | |||

| G | L1C, L2C, 24 V, 0 V, DB1, DB2, DB3, DB4, NC | M5 | 1.0 to 1.7 | ||

| L1, L2, L3, B1, B2, NC, U, V, W | M5 | 2.0 to 2.4 | M3 | 0.3 to 0.5 | |

| H | L1C, L2C, 24 V, 0 V, DB1, DB2 | M4 | 0.7 to 1.0 | M5 | 2.0 to 2.5 |

| L1, L2, L3, B1, B2, NC, U, V, W | M6 | 2.2 to 2.5 | |||

■Fastening torque list (Ground terminal screw/Connector to host controller [X4])

| Driver frame | Ground screw | Connector to host controller (X4) | ||

|---|---|---|---|---|

| Nominal size | Fastening torque (N・m) | Nominal size | Fastening torque (N・m) | |

| A to E | M4 | 0.7 to 0.8 | M2.6 | 0.2±0.05 |

| G | M5 | 1.4 to 1.6 | ||

| H | M6 | 2.4 to 2.6 | ||

[Caution]

- Applying fastening torque larger than the maximum value may result in damage to the product.

- Do not turn on power without tightening all terminal block screws properly, otherwise, loose contacts may generate heat (smoking, firing).

[Remarks]

- To check for looseness, conduct periodic inspection of fastening torque once a year.

Driver Specifications

A5Ⅱ, A5 series

(Speed, Position, Torque, Full-Closed type)

Basic Specifications

| Item | Specifications | |||

|---|---|---|---|---|

| Input power | 100 V | Main circuit | Single phase, 100 V (+10 % -15 %) to 120 V (+10 % -15 %) 50 Hz / 60 Hz | |

| Control circuit | Single phase, 100 V (+10 % -15 %) to 120 V (+10 % -15 %) 50 Hz / 60 Hz | |||

| 200 V | Main circuit | A-frame to D-frame | Single/3-phase, 200 V (+10 % -15 %) to 240 V (+10 % -15 %) 50 Hz / 60 Hz | |

| E-frame to H-frame | 3-phase, 200 V (+10 % -15 %) to 230 V (+10 % -15 %) 50 Hz / 60 Hz | |||

| Control circuit | A-frame to D-frame | Single phase, 200 V (+10 % -15 %) to 240 V (+10 % -15 %) 50 Hz / 60 Hz | ||

| E-frame to H-frame | Single phase, 200 V (+10 % -15 %) to 230 V (+10 % -15 %) 50 Hz / 60 Hz | |||

| 400 V | Main circuit | D-frame to H-frame | 3-phase, 380 V (+10 % -15 %) to 480 V (+10 % -15 %) 50 Hz / 60 Hz | |

| Control circuit | D-frame to H-frame | DC 24 V ± 15 % | ||

| Environment | temperature | Ambient temperature: 0 ˚C to 55 ˚C (free from freezing) Storage temperature: –20 ˚C to 65 ˚C (Max.temperature guarantee: 80 ˚C for 72 hours free from condensation*1) | ||

| humidity | Both operating and storage : 20 % to 85 %RH (free from condensation*1) | |||

| Altitude | Lower than 1000 m | |||

| Vibration | 5.88 m/s2 or less, 10 Hz to 60 Hz | |||

| Control method | IGBT PWM Sinusoidal wave drive | |||

| Encoder feedback | 17-bit (131072 resolution) absolute encoder, 7-wire serial 20-bit (1048576 resolution) incremental encoder, 5-wire serial | |||

| Feedback scale feedback | A/B phase | A/B phase, initialization signal defferential input. | ||

| serial | Manufacturers that support serial communication scale: | |||

| Parallel I/O connector | Control signal | Input | General purpose 10 inputs The function of general-purpose input is selected by parameters. | |

| Output | General purpose 6 outputs The function of general-purpose output is selected by parameters. | |||

| Analog signal | Input | 3 inputs (16-bit A/D : 1 input, 12-bit A/D : 2 inputs) | ||

| Output | 2 outputs (Analog monitor: 2 output) | |||

| Pulse signal | Input | 2 inputs (Photo-coupler input, Line receiver input) | ||

| Output | 4 outputs ( Line driver: 3 output, open collector: 1 output) | |||

| Communication function | USB | Connection with PC etc. | ||

| RS232 | 1:1 communication | |||

| RS485 | 1: n communication (max 31) | |||

| Safety function | Used for functional safety. | |||

| Front panel | (1) 5 keys (2) LED (6-digit) (3) Connector for monitor (Analog monitor output (2ch), Digital monitor output (1ch)) | |||

| Regeneration | A, B,G and H-frame: no built-in regenerative resistor (external resistor only) C-frame to F-frame: Built-in regenerative resistor (external resistor is also enabled.) | |||

| Dynamic brake | A-frame to G-frame: Built-in (external resistor is also enabled to G-frame.) H-frame: External only | |||

| Control mode | Switching among the following 7 mode is enabled, (1) Position control (2) Speed control (3) Toque control (4) Position/Speed control (5) Position/Torque control (6) Speed/Torque control (7) Full-closed control | |||

*1 Air containing water vapor will become saturated with water vapor as the temperature falls, causing dew.

*2 Not applicable to 2DOF control system.

Function

| Item | Specifications | ||

|---|---|---|---|

| Control input | (1) Deviation counter clear (2) Command pulse inhibitation (3) Electric gear (4) Damping control switching etc. | ||

| Control output | Positioning complete (In-position) etc. | ||

| Position control | Pulse input | Max. command pulse frequency | Exclusive interface for Photo-coupler: 500 kpps |

| Input pulse signal format | Differential input ((1) Positive and Negative direction, (2) A and B-phase, (3) Command and direction) | ||

| Electronic gear (Division/Multiplication of command pulse) | 1/1000 times to 1000 times | ||

| Smoothing filter | Primary delay filter or FIR type filter is adaptable to the command input | ||

| Analog input | Torque limit command input | Individual torque limit for both positive and negative direction is enabled. | |

| Torque feed forward input | Analog voltage can be used as torque feed forward input. | ||

| Instantaneous Speed Observer | Available | ||

| Damping Control | Available | ||

| 2DOF settings | Only available at A5Ⅱ Series | ||

| Speed control | Control input | (1) Selection of internal velocity setup 1 (2) Selection of internal velocity setup 2 (3) Selection of internal velocity setup 3 (4) Speed zero clamp etc. | |

| Control output | Speed arrival etc. | ||

| Analog input | Velocity command input | Speed command input can be provided by means of analog voltage. Parameters are used for scale setting and command polarity. (6 V/Rated rotational speed Default) | |

| Torque limit command input | Individual torque limit for both positive and negative direction is enabled. | ||

| Torque feed forward input | Analog voltage can be used as torque feed forward input. | ||

| Internal velocity command | Switching the internal 8speed is enabled by command input. | ||

| Soft-start/down function | Individual setup of acceleration and deceleration is enabled, with 0 s to 10 s/ 1000 r/min. Sigmoid acceleration/deceleration is also enabled. | ||

| Zero-speed clamp | Speed zero clamp input is enabled. | ||

| Instantaneous Speed Observer | Available | ||

| Speed Control filter | Available | ||

| 2DOF settings | Only available at A5Ⅱ Series | ||

| Torque contro *2 | Control input | Speed zero clamp, Torque command sign input etc. | |

| Control output | Speed arrival etc. | ||

| Analog input | Torque command input | Speed command input can be provided by means of analog voltage. Parameters are used for scale setting and command polarity. (3 V/rated torque Default) | |

| Speed limit function | Speed limit value with parameter is enabled. | ||

| Full-closed control *2 | Control input | (1) Deviation counter clear (2) Command pulse inhibition (3) Command dividing gradual increase switching (4) Damping control switching etc. | |

| Control output | Full-closed positioning complete etc. | ||

| Pulse input | Max. command pulse frequency | Exclusive interface for Photo-coupler: 500 kpps Exclusive interface for line driver: 4 Mpps | |

| Input pulse signal format | Differential input | ||

| Electronic gear (Division/ Multiplication of command pulse) | 1/1000 times to 1000 times | ||

| Smoothing filter | Primary delay filter or FIR type filter is adaptable to the command input | ||

| Analog input | Torque limit command input | Individual torque limit for both positive and negative direction is enabled. | |

| Torque feed forward input | Analog voltage can be used as torque feed forward input. | ||

| Setup range of division/multiplication of feedback scale | 1/40 times to 160 times | ||

| Damping Control | Available | ||

| Common | Auto tuning | The load inertia is identified in real time by the driving state of the motor operating according to the command given by the controlling device and set up support software “PANATERM”. The gain is set automatically in accordance with the rigidity setting. | |

| Division of encoder feedback pulse | Set up of any value is enabled (encoder pulses count is the max.). | ||

| Protective function | Hard error | Over-voltage, under-voltage, over-speed, over-load, over-heat, over-current and encoder error etc. | |

| Soft error | Excess position deviation, command pulse division error, EEPROM error etc. | ||

| Traceability of alarm data | The alarm data history can be referred to. | ||

A5ⅡE, A5E series

(Position control type)

Basic Specifications

| Item | Specifications | |||

|---|---|---|---|---|

| Input power | 100 V | Main circuit | Single phase, 100 V (+10 % -15 %) to 120 V (+10 % -15 %) 50 Hz / 60 Hz | |

| Control circuit | Single phase, 100 V (+10 % -15 %) to 120 V (+10 % -15 %) 50 Hz / 60 Hz | |||

| 200 V | Main circuit | A-frame to D-frame | Single/3-phase, 200 V (+10 % -15 %) to 240 V (+10 % -15 %) 50 Hz / 60 Hz | |

| E-frame to F-frame | 3-phase, 200 V (+10 % -15 %) to 230 V (+10 % -15 %) 50 Hz / 60 Hz | |||

| Control circuit | A-frame to D-frame | Single phase,200 V (+10 % -15 %) to 240 V (+10 % -15 %) 50 Hz / 60 Hz | ||

| E-frame to F-frame | Single phase, 200 V (+10 % -15 %) to 230 V (+10 % -15 %) 50 Hz / 60 Hz | |||

| 400 V | Main circuit | D-frame to F-frame | 3-phase, 380 V (+10 % -15 %) to 480 V (+10 % -15 %) 50 Hz / 60 Hz | |

| Control circuit | D-frame to F-frame | DC 24 V ± 15 % | ||

| Environment | temperature | Ambient temperature: 0 ˚C to 55 ˚C (free from freezing) Storage temperature: –20 ˚C to 65 ˚C (Max.temperature guarantee: 80 ˚C for 72 hours free from condensation*1) | ||

| humidity | Both operating and storage : 20 % to 85 %RH (free from condensation*1) | |||

| Altitude | Lower than 1000 m | |||

| Vibration | 5.88 m/s2 or less, 10 Hz to 60 Hz | |||

| Control method | GBT PWM Sinusoidal wave drive | |||

| Encoder feedback | 20-bit (1048576 resolution) incremental encoder, 5-wire serial | |||

| Parallel I/O connector | Control signal | Input | General purpose 10 inputs The function of general-purpose input is selected by parameters. | |

| Output | General purpose 6 outputs The function of general-purpose output is selected by parameters. | |||

| Analog signal | Input | none | ||

| Output | 2 outputs (Analog monitor: 2 output) | |||

| Pulse signal | Input | 2 inputs (Photo-coupler input, Line receiver input) | ||

| Output | 4 outputs ( Line driver: 3 output, open collector: 1 output) | |||

| Communication function | USB | Connection with PC etc. | ||

| Front panel | (1) 5 keys (2) LED (6-digit) (3) Analog monitor output (2ch) | |||

| Regeneration | A, B-frame: no built-in regenerative resistor (external resistor only) C-frame to F-frame: Built-in regenerative resistor (external resistor is also enabled.) | |||

| Dynamic brake | Built-in | |||

| Control mode | (1) Position control (2) Internal velocity control (3) Position/ Internal velocity control | |||

*1 Air containing water vapor will become saturated with water vapor as the temperature falls, causing dew.

Function

| Item | Specifications | ||

|---|---|---|---|

| Position control | Control input | (1) Deviation counter clear (2) Command pulse inhibitation (3) Electric gear (4) Damping control switching etc. | |

| Control output | Positioning complete (In-position) etc. | ||

| Pulse input | Max. command pulse frequency | Exclusive interface for Photo-coupler: 500 kpps Exclusive interface for line driver: 4 Mpps | |

| Input pulse signal format | Differential input ((1) Positive and Negative direction, (2) A and B-phase, (3) Command and direction) | ||

| Electronic gear (Division/ Multiplication of command pulse) | 1/1000 times to 1000 times | ||

| Smoothing filter | Primary delay filter or FIR type filter is adaptable to the command input | ||

| Instantaneous Speed Observer | Available | ||

| Damping Control | Available | ||

| 2DOF settings | Only available at A5ⅡE Series | ||

| Common | Auto tuning | The load inertia is identified in real time by the driving state of the motor operating according to the command given by the controlling device and set up support software “PANATERM”. The gain is set automatically in accordance with the rigidity setting. | |

| Division of encoder feedback pulse | Set up of any value is enabled (encoder pulses count is the max.). | ||

| Protective function | Hard error | Over-voltage, under-voltage, over-speed, over-load, over-heat, over-current and encoder error etc. | |

| Soft error | Excess position deviation, command pulse division error, EEPROM error etc. | ||

| Traceability of alarm data | The alarm data history can be referred to. | ||

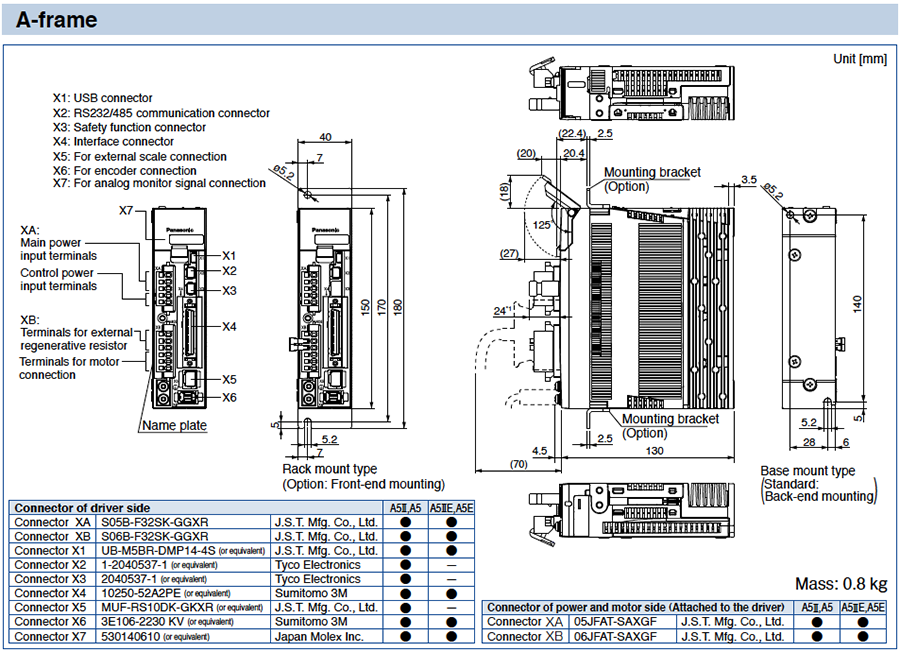

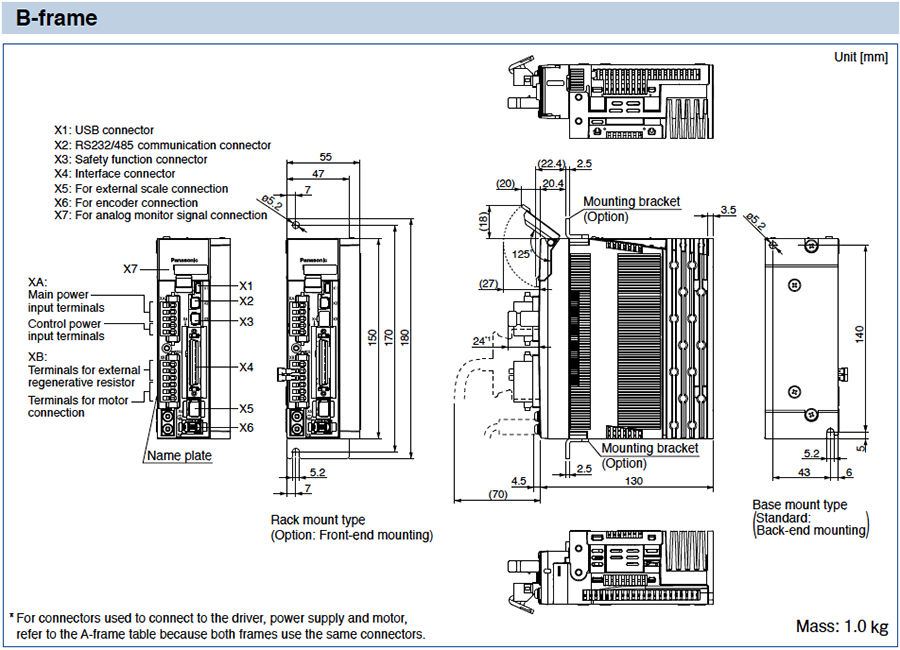

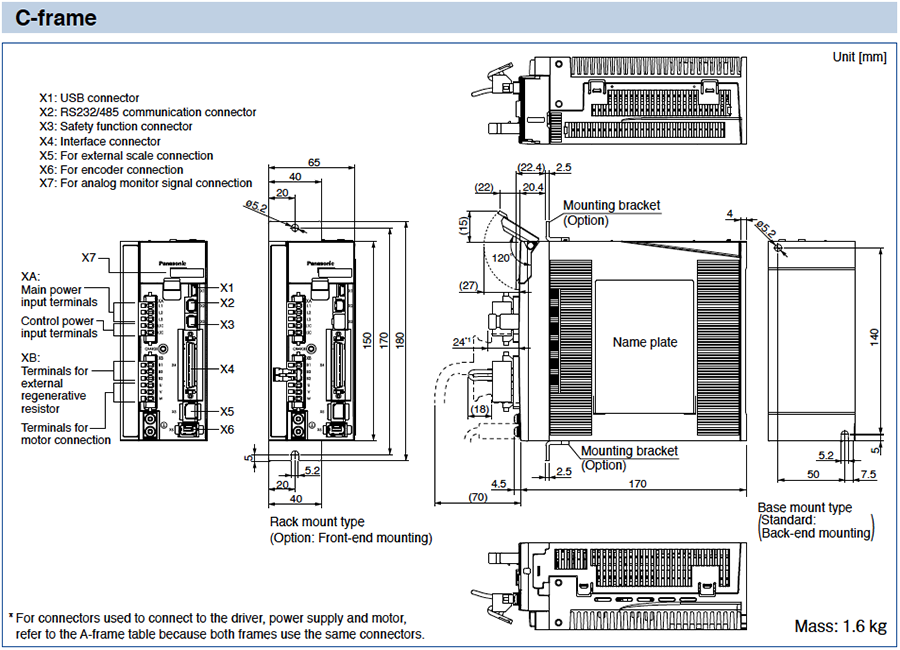

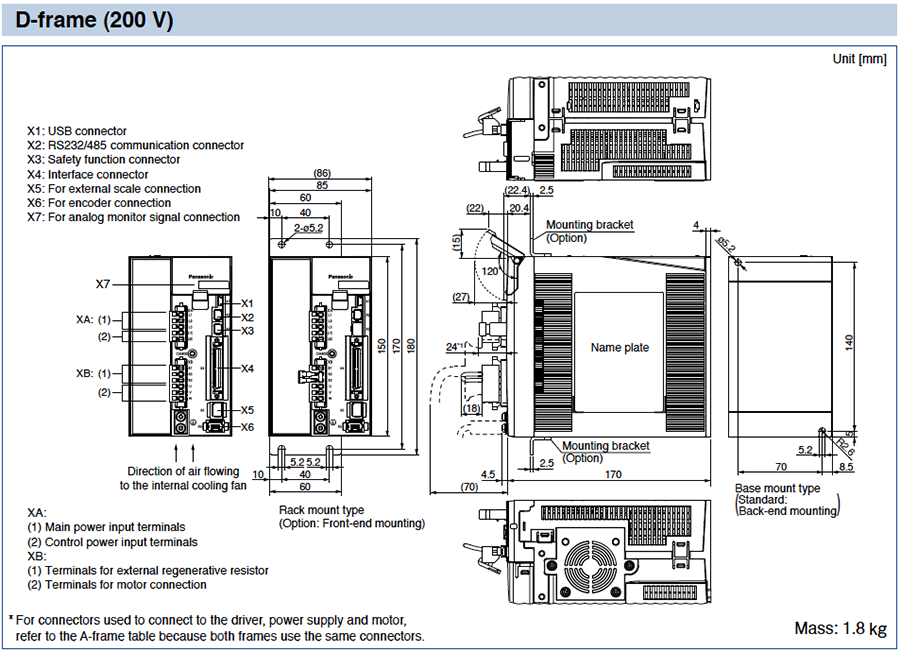

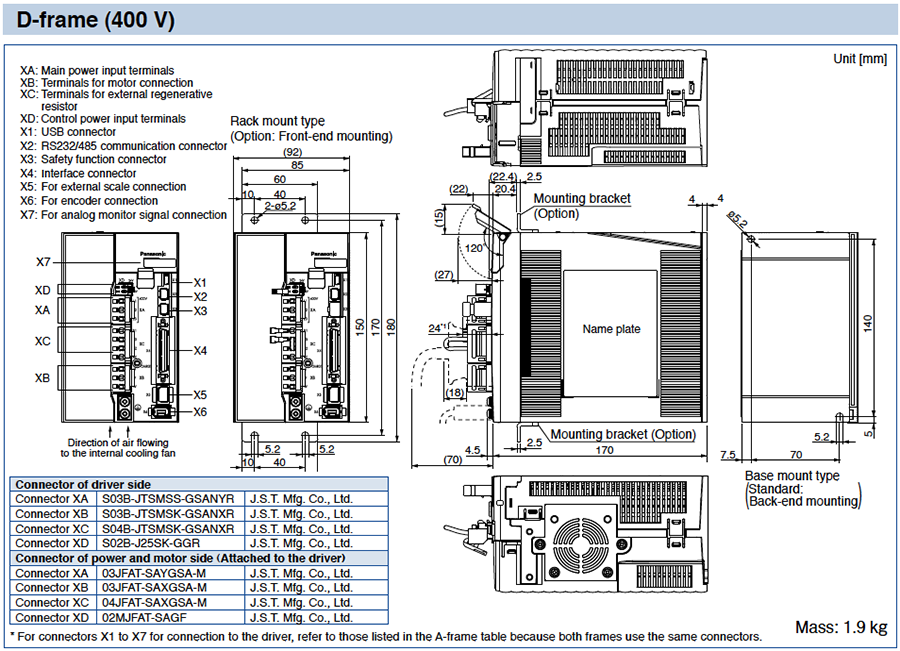

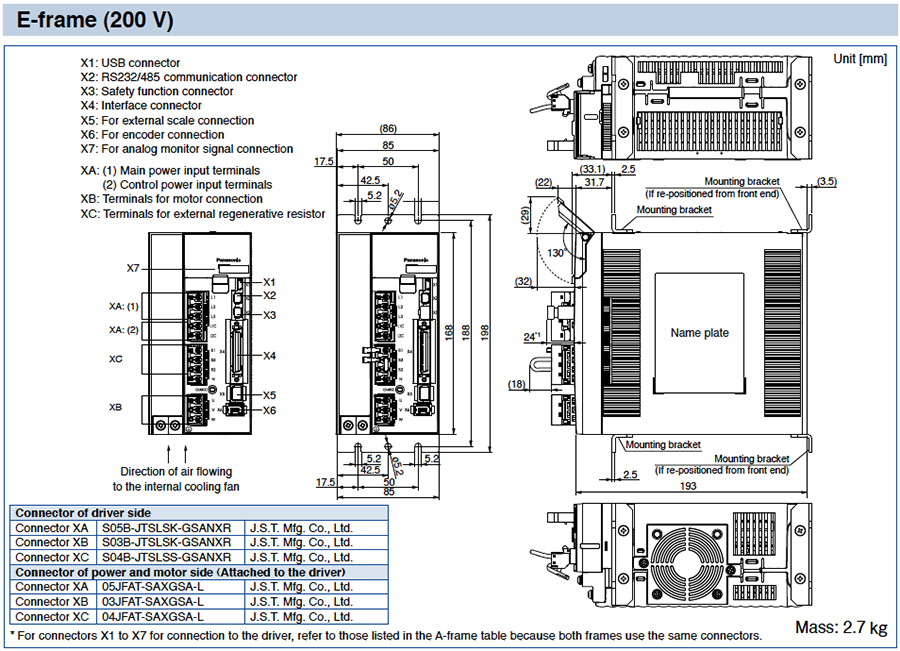

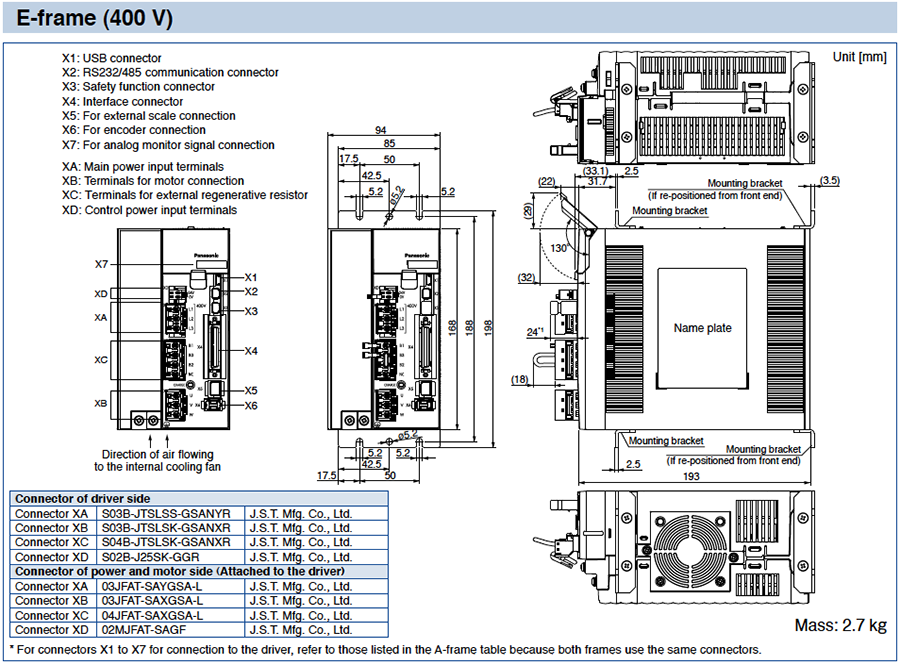

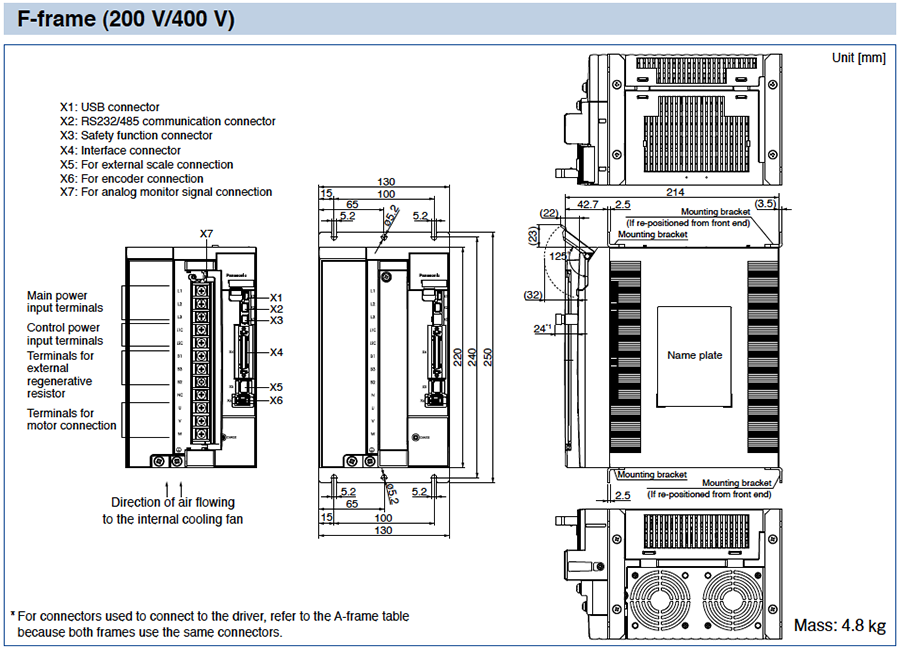

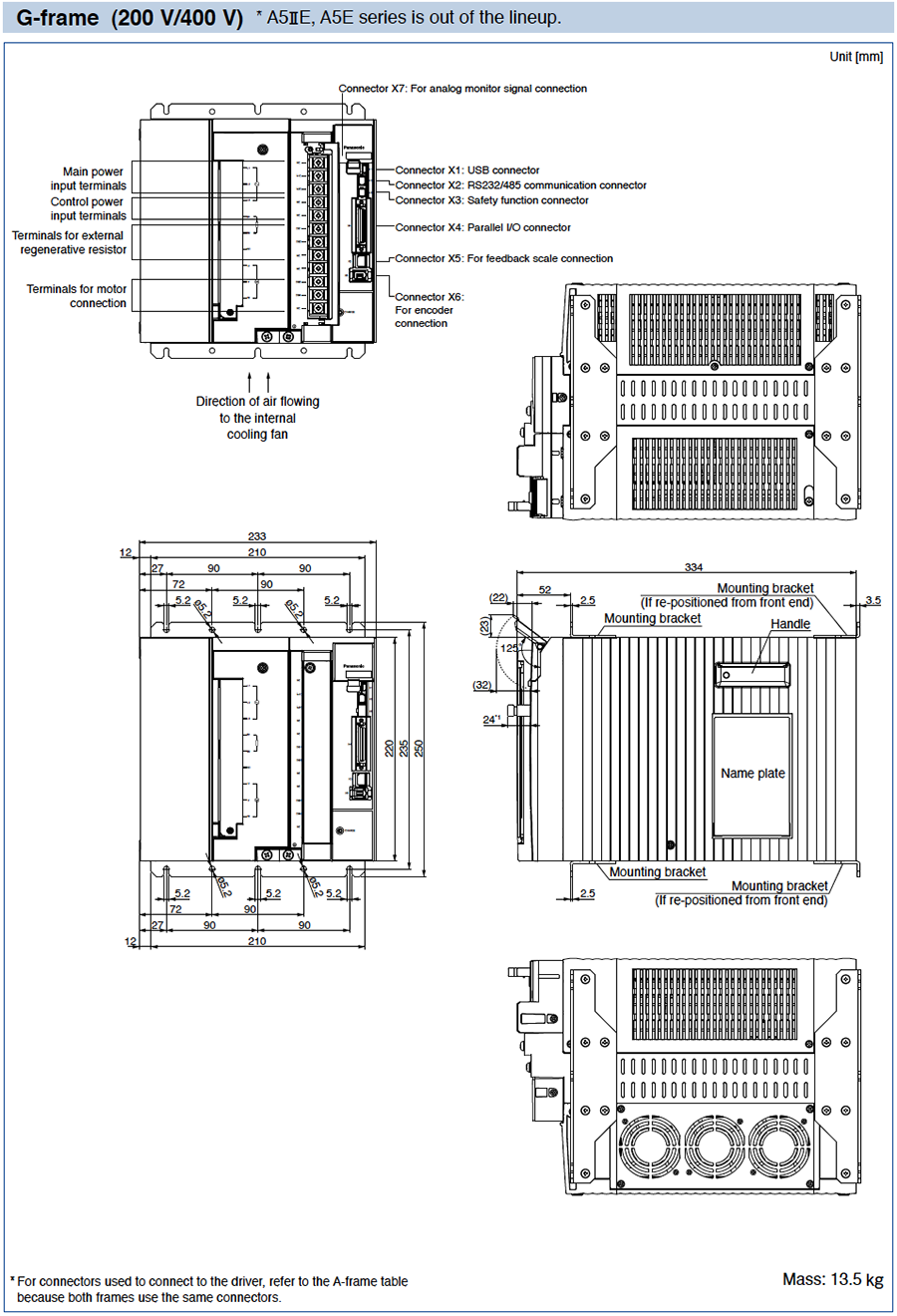

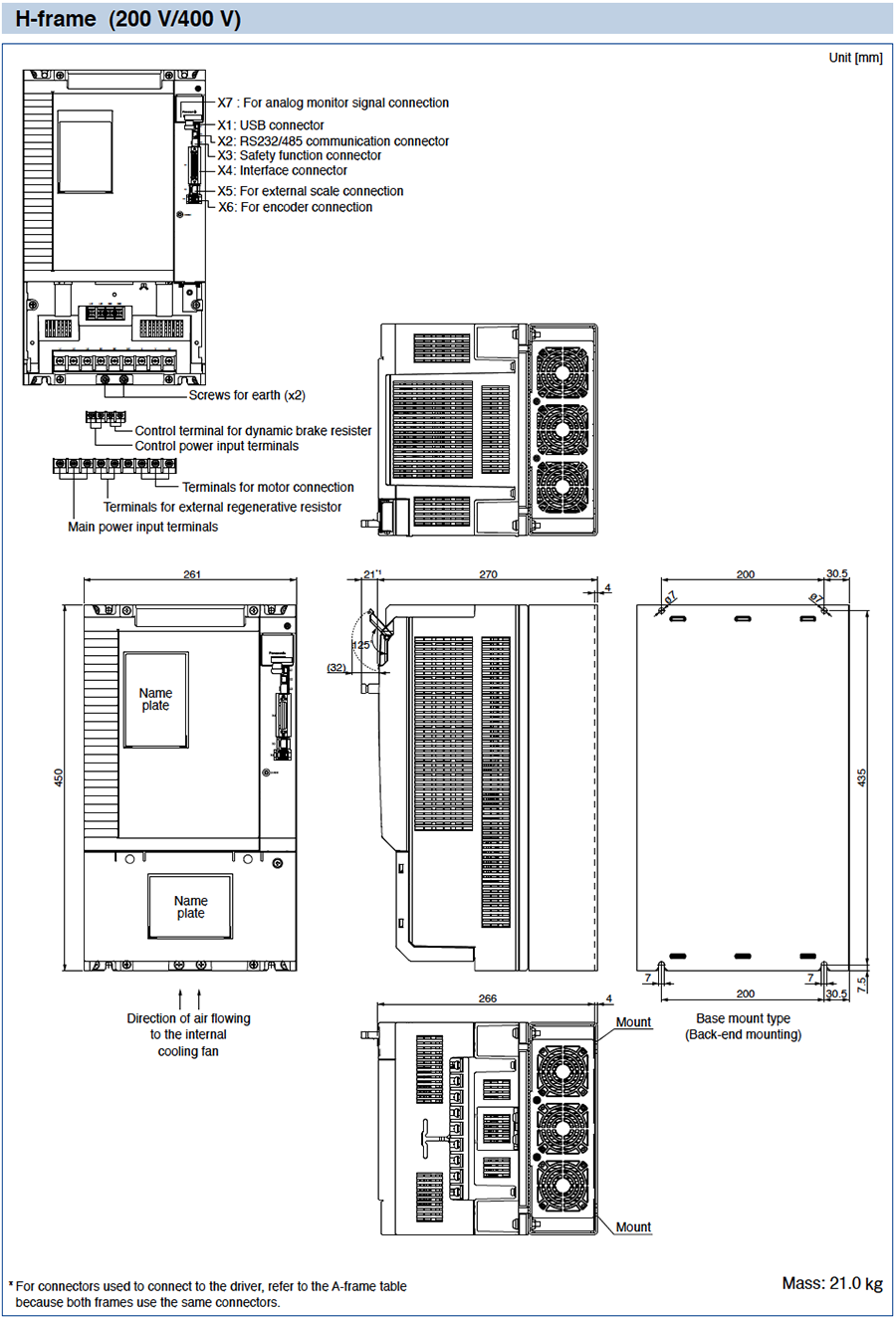

Dimensions

Dimensions of Motor

For Motors, please refer to each part number detail.

Dimensions of Driver

● The size of A5Ⅱ, A5 series and A5ⅡE, A5E series is same.

*1 The height of the safety by-pass provided plug is one of the 14 mm or 24 mm to connector X3.

●A5ⅡE, A5E series is out of the lineup.

*1 The height of the safety by-pass provided plug is one of the 11 mm or 21 mm to connector X3.

- 1.Wiring Diagram (Wiring to Connector, XA, XB, XC, XD and Terminal Block)

- 2.Safety Function (Wiring to the Connector, X3)

- 3.Control Circuit Diagram (Wiring to the Connector, X4, X5, X6)

1.Wiring Diagram

Wiring to Connector, XA, XB, XC, XD and Terminal Block

Note.1)

| Frame No. | Short wire (Accessory) | Built-in regenerative resistor | Connection of the connector XB | |

|---|---|---|---|---|

| In case of using an external regenerative resistor. | In case of not using an external regenerative resistor. | |||

| A-frame B-frame | without | without | ・Always open between B2-B3 ・Connect an external regenerative resistor between B1-B2 | ・Always open between B2-B3 |

| C-frame D-frame | with | with | ・Remove the short wire accessory from between B2-B3. ・Connect an external regenerative resistor between B1-B2 | ・Shorted between B2-B3 with an attached short wire |

Note.1)

| Frame No. | Short wire (Accessory) | Built-in regenerative resistor | Connection of the connector XB | |

|---|---|---|---|---|

| In case of using an external regenerative resistor. | In case of not using an external regenerative resistor. | |||

| A-frame B-frame | without | without | ・Always open between B2-B3 ・Connect an external regenerative resistor between B1-B2 | ・Always open between B2-B3 |

| C-frame D-frame | with | with | ・Remove the short wire accessory from between B2-B3. ・Connect an external regenerative resistor between B1-B2 | ・Shorted between B2-B3 with an attached short wire |

Note.1)

| Frame No. | Short wire (Accessory) | Built-in regenerative resistor | Connection of the connector XC | |

|---|---|---|---|---|

| In case of using an external regenerative resistor. | In case of not using an external regenerative resistor. | |||

| E-frame | with | with | ・Remove the short wire accessory from between B2-B3. ・Connect an external regenerative resistor between B1-B2 | ・Shorted between B2-B3 with an attached short wire |

Note.1)

| Frame No. | Short bar (Accessory) | Built-in regenerative resistor | Connection of terminal block | |

|---|---|---|---|---|

| In case of using an external regenerative resistor. | In case of not using an external regenerative resistor. | |||

| F-frame | with | with | • Remove the short bar accessory from between B2-B3. • Connect an external regenerative resistor between B1-B2 | • Shorted between B2-B3 with an attached short bar |

Note.1) About regenerative resistor

| Frame No. | Short bar (Accessory) | Built-in regenerative resistor | Connection of terminal block | |

|---|---|---|---|---|

| In case of using an external regenerative resistor. | In case of not using an external regenerative resistor. | |||

| G-frame | without | without | • Connect an external regenerative resistor between B1-B2 | • Open between B1-B2 |

Note.2) About dynamic brake resistor

| Frame No. | Short bar (Accessory) | Built-in dynamic brake resistor | Connection of terminal block | |

|---|---|---|---|---|

| In case of using an external dynamic brake resistor. | In case of not using an external dynamic brake resistor. | |||

| G-frame | with | with | • Remove attached short bar between DB3-DB4. • Connect external dynamic brake resistor as shown above. | • Shorted with attached short bar between DB3-DB4 • Open between DB1-DB2 |

Note.1) About regenerative resistor

| Frame No. | Short bar (Accessory) | Built-in regenerative resistor | Connection of terminal block | |

|---|---|---|---|---|

| In case of using an external regenerative resistor. | In case of not using an external regenerative resistor. | |||

| H-frame | without | without | (External regenerative resistor terminal) • Terminal R1, R2 connect to B1, B2 • Terminal T1, T2 connection as shown above • Terminal 24 V, 0 V connect to DC power supply of DC24 V. • E terminal connect to the ground | • Open between B1-B2 |

Specification of external regenerative resistor, please refer to “Options Components”.

Note.2) About dynamic brake resistor

| Frame No. | Short bar (Accessory) | Built-in dynamic brake resistor | Connection of terminal block | |

|---|---|---|---|---|

| In case of using an external dynamic brake resistor. | In case of not using an external dynamic brake resistor. | |||

| H-frame | without | without | • Connect external dynamic brake resistor as shown above. | • Open between DB1-DB2 |

<common for G & H frame>

Note.3) Magnetic contactor MC2 must be the same rating as the contactor MC1 in the main circuit.

Note.4) Servo may be turned on in the external sequence if the contact deposits: to protect the system, provide the auxiliary contact.

Note.5) Provide an external protective device (e.g. thermal fuse) to monitor the temperature of the external dynamic brake resistor.

Note.6) Reactor should be prepared by the customer.

Note.1) Shielding the circuit is recommended for the purpose of noise reduction.

Note.2)

| Frame No. | Short wire (Accessory) | Built-in regenerative resistor | Connection of the connector XC | |

|---|---|---|---|---|

| In case of using an external regenerative resistor. | In case of not using an external regenerative resistor. | |||

| E-frame | with | with | • Remove the short wire accessory from between B2-B3. • Connect an external regenerative resistor between B1-B2 | • Shorted between B2-B3 with an attached short wire |

Note.1) Shielding the circuit is recommended for the purpose of noise reduction.

Note.2)

| Frame No. | Short bar (Accessory) | Built-in regenerative resistor | Connection of terminal block | |

|---|---|---|---|---|

| In case of using an external regenerative resistor. | In case of not using an external regenerative resistor. | |||

| F-frame | with | with | ・Remove the short wire accessory from between B2-B3. ・Connect an external regenerative resistor between B1-B2 | ・Shorted between B2-B3 with an attached short bar |

Note.1) About regenerative resistor

| Frame No. | Short bar (Accessory) | Built-in regenerative resistor | Connection of terminal block | |

|---|---|---|---|---|

| In case of using an external regenerative resistor. | In case of not using an external regenerative resistor. | |||

| G-frame | without | without | • Connect an external regenerative resistor between B1-B2 | • Open between B1-B2 |

Note.2) About dynamic brake resistor

| Frame No. | Short bar (Accessory) | Built-in dynamic brake resistor | Connection of terminal block | |

|---|---|---|---|---|

| In case of using an external dynamic brake resistor. | In case of not using an external dynamic brake resistor. | |||

| G-frame | with | with | • Remove attached short bar between DB3-DB4. • Connect external dynamic brake resistor as shown above. | • Shorted with attached short bar between DB3-DB4 • Open between DB1-DB2 |

Note.1) About regenerative resistor

| Frame No. | Short bar (Accessory) | Built-in regenerative resistor | Connection of terminal block | |

|---|---|---|---|---|

| In case of using an external regenerative resistor. | In case of not using an external regenerative resistor. | |||

| H-frame | without | without | (External regenerative resistor terminal) • Terminal R1, R2 connect to B1, B2 • Terminal T1, T2 connection as shown above • Terminal 24 V, 0 V connect to DC power supply of DC24 V . • E terminal connect to the ground | • Open between B1-B2 |

Specification of external regenerative resistor, please refer to “Options Components”.

Note.2) About dynamic brake resistor

| Frame No. | Short bar (Accessory) | Built-in dynamic brake resistor | Connection of terminal block | |

|---|---|---|---|---|

| In case of using an external dynamic brake resistor. | In case of not using an external dynamic brake resistor. | |||

| H-frame | without | without | • Connect external dynamic brake resistor as shown above. | • Open between DB1-DB2 |

<common for G & H frame>

Note.3) Shielding the circuit is recommended for the purpose of noise reduction.

Note.4) Magnetic contactor MC2 must be the same rating as the contactor MC1 in the main circuit.

Note.5) Servo may be turned on in the external sequence if the contact deposits: to protect the system, provide the auxiliary contact.

Note.6) Provide an external protective device (e.g. thermal fuse) to monitor the temperature of the external dynamic brake resistor.

Note.7) Reactor should be prepared by the customer.

2.Safety Function

Wiring to the Connector, X3 (Excluding A5ⅡE, A5E Series)

Connecting the host controller can configure a safety circuit that controls the safety functions.

When not constructing the safety circuit, use the supplied safety bypass plug.

Outline Description of Safe Torque Off (STO)

The safe torque off (STO) function is a safety function that shuts the motor current and turns off motor output torque by forcibly turning off the driving signal of the servo driver internal power transistor. For this purpose, the STO uses safety input signal and hardware (circuit).

When STO function operates, the servo driver turns off the servo ready output signal (S-RDY) and enters safety state.

This is an alarm condition and the 7-seg LED on the front panel displays the error code number.

Safety Precautions

- When using the STO function, be sure to perform equipment risk assessment to ensure that the system conforms to the safety requirements.

- Even while the STO function is working, the following potential safety hazards exist. Check safety in risk assessment.

- The motor may move when external force (e.g. gravity force on vertical axis) is exerted on it. Provide an external brake, etc., as necessary to secure the motor. Note that the purpose of motor with brake is holding and it cannot be used for braking application.

- When parameter Pr5.10 Sequence at alarm is set to free run (disable dynamic brake), the motor is free run state and requires longer stop distance even if no external force is applied. Make sure that this does not cause any problem.

- When power transistor, etc., becomes defective, the motor will move to the extent equivalent of 180 electrical angle (max.). Make sure that this does not cause any problem.

- The STO turns off the current to the motor but does not turn off power to the servo driver and does not isolate it. When starting maintenance service on the servo driver, turn off the driver by using a different disconnecting device.

- External device monitor (EDM) output signal is not a safety signal. Do not use it for an application other than failure monitoring.

- Dynamic brake and external brake release signal output are not related to safety function. When designing the system, make sure that the failure of external brake release during STO condition does not result in danger condition.

- When using STO function, connect equipment conforming to the safety standards.

[Connector pin assignment]

(Viewed from cable)

* Do not connect anything to NC.

●System configuration

3.Control Circuit Diagram

Wiring to the Connector, X4

Note

Do not connect anythig to PIN No.14,15,16,18.

Wiring to the Connector, X5 (Excluding A5ⅡE, A5E series)

Applicable External Scale

The manufacturers applicable external scales for this product are as follows.

- DR. JOHANNES HEIDENHAIN GmbH

- Fagor Automation S.Coop

- Magnescale Co., Ltd.

- Mitutoyo Corporation

- NIDEC INSTRUMENTS CORPORATION

- Renishaw plc

* For the details of the external scale product, contact each company.

Wiring to the Connector, X6

Software

Setup Software

Setup Support Software "PANATERM"

Software Download

Software are available for download.

*To download, you need to enter your customer information.

>>Go to Data download.