Digital Fiber Sensor FX-550L

Download

-

Basic Information

-

Applications

-

Order guide

-

Option

-

Specifications

-

Dimensions

-

Circuit/ Wiring

-

List of fibers

-

Cautions For Use

------------------------------ Tab1 showing ------------------------------

Basic Information

Reduction of the data analysis burden - one small step towards IoT.

IO-Link Compatible, Self-Monitoring Type

Contact Us

IO-Link Compatible Devices Line UP

Features

Reduction of the data analysis burdenone small step towards IoT.

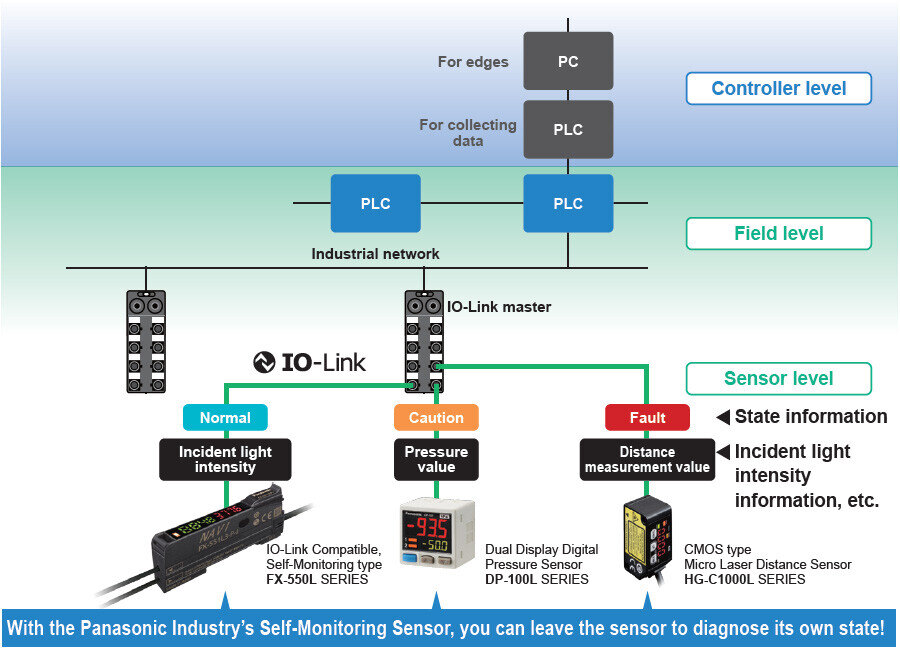

IO-Link compatible Collecting sensor level data

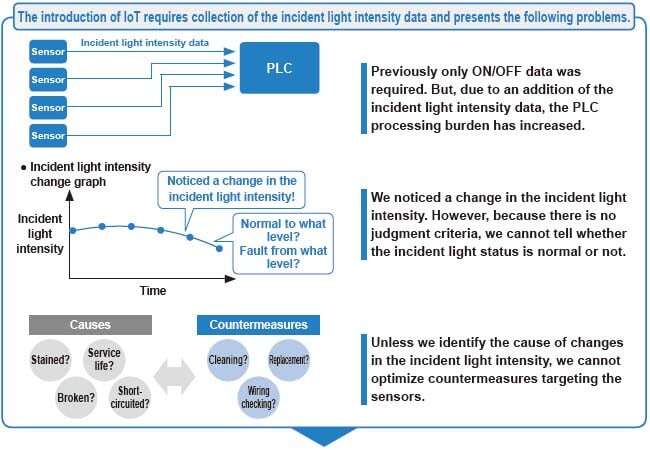

Field data collected and accumulated for “preventive maintenance” and “operation monitoring”.

An analysis of such field data requires high-level know-how and time, causing a burden to people responsible for the production site management.

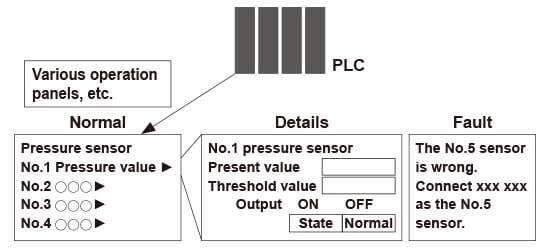

The Self-Monitoring Sensor manufactured by Panasonic Industry is capable of reporting sensor data and its own state to the host device through the I/O Link master.

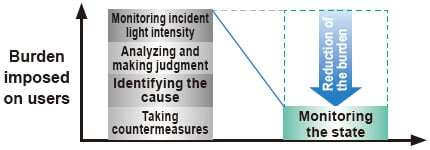

With the Self-Monitoring Sensor, you can immediately judge the state of the sensor and easily identify the cause of failure. Thus, this sensor contributes to the reduction of the burden experienced by the client in collecting and analyzing data.

Incorporated self-monitoring function

With the Panasonic Industry's Self-Monitoring Sensor,you can get high-level solutions!

Problems are solved by the Self-monitoring function.

| Status | Judgement of the state | ||

|---|---|---|---|

| Normal | Operation is normal. | ||

| Notification | Check the settings. Detected state is faulty. | * Recover to the normal state through checking installation and settings. Reduction in the incident light intensity | |

| Caution | Getting close to the end of service life. Reached the state where the device should be replaced. | * Limitation in the writing frequency into the memory or in the operation hours, etc. | |

| Fault | Short-circuited or broken. Reached the state where it is impossible to control as a device. | * Short-circuited output, damaged EEPROM, etc. | |

*

By creating a program with a PLC, etc., the "State" of the self-monitoring sensor can be grasped.

Software are available for download. *Membership registration is required to access/download this data.

>>Go to Data download.

Easy use of IoT

“Predictive maintenance” can be easily achieved through monitoring the state of the Self-Monitoring Sensor.

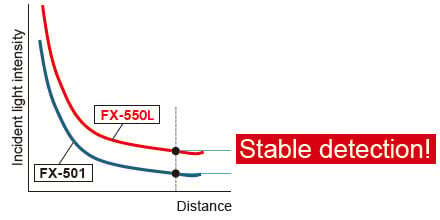

Emission power: 3 times the conventional ratio, Sensing range: 1.6 times max.!

Largely improved stability and ease of use due to higher emission power and broader utility!

This digital fiber sensor realizes longer sensing range than expected even with thin fibers.

| Fiber | Sensing range(STD mode) | Rate of increase in sensing range | |

|---|---|---|---|

| FX-550LSERIES | FX-501 | ||

| FT-31 | 480mm18.898 in | 315mm 12.402 in | 152% |

| FT-42 | 1,470mm57.874 in | 1,130mm 44.488 in | 130% |

| FD-41 | 200mm7.874 in | 125mm 4.921 in | 160% |

| FD-61 | 620mm24.409 in | 450mm 17.717 in | 138% |

When the hysteresis is the same, the higher incident light intensity results in more stable detection.

When the hysteresis is the same, the higher incident light intensity results in more stable detection.

Easy adjustment of beam axis

Thanks to the high emission power, a slight deviation of beam axis causes no problem. It is ideal for use in dusty areas* or for detection through an extremely small slit.

* Need to confirm proper operation in installed condition.

Equipped with a mode to minimize the effect of ambient light

When setting to activate the environment resistance mode in the emission frequency setting, the ambient illuminance for LED lights becomes about 2.5 times higher than that in the normal mode. This reduces erroneous detections caused by LED lights.

Simplified functions for improved operation ease

The FX-500 series and newer models are equipped with only basic functions for improved ease of use. No matter which model you select, they are all easy to use.

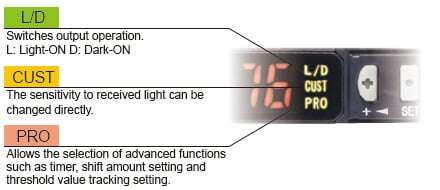

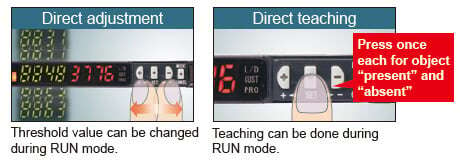

MODE NAVI + Direct setting

MODE NAVI uses three indicators and a dual display to show the amplifier’s basic operations. The current operation mode can be confirmed at a glance, so even a first-time user can easily operate the amplifier.

■NAVI display (lights off during RUN mode)

■Direct setting

Note:When connecting to upper communication unit, SC-GU3 series/SC-GU1-485, please select FX-500 series.

■List of functions in PRO mode

| PRO 1 | Response time setting, timer setting, shift amount setting |

|---|---|

| PRO 2 | Teaching lock setting, digital display item setting, digital display turning setting, Eco setting |

| PRO 3 | Display adjustment setting, reset setting, emission frequency setting, threshold value tracking setting |

------------------------------ Tab2 showing ------------------------------

Applications

IoT Examples at FA Sites

Before the introduction of Self-Monitoring Sensors

Preventive maintenance

●We want to avoid production line stoppage that might occur due to unexpected sensor failure.

Line stoppage hours × (manufacturing unit cost / hour) = Loss

●We want to minimize the production line down time to almost zero.

Problems

◆The amount of data to be collected is large and this may lower the PLC processing capacity.

◆The burden of data analysis is large.

◆Resetting the replaced sensors is troublesome.

After the introduction of Self‑Monitoring Sensors

From preventive maintenance to predictive maintenance

Leave the sensor diagnosis to the sensor itself.

●All you need to do is to monitor the sensor state.

●PLC can be used exclusively for controlling devices.

●Possible to check detail information at a desired timing.

Leave the resetting for replaced sensors to the higher-level master

●Automatically written from the connected master.

●Possible not only to save time but also to prevent human errors.

IoT Examples at FA Sites 02

Before the introduction of Self-Monitoring Sensors

Remote controlling

and batch settings

●We want to place sensors close to sensing points as much as possible.

However, it is often difficult to make settings, particularly when there are many sensors to install.

●We want to send predetermined parameter values in a batch file for a repeater, etc.

●We want to confirm that required sensors are properly connected at the startup of the system.

Problems

◆It takes time to set sensors.

◆We want to avoid mistakes in setting sensors or wiring.

After the introduction of Self‑Monitoring Sensors

Fully utilize the advantages of the IO‑Link output.

●Possible to read or write set values through external

interface.

●Possible to set multiple sensors in a batch process.

●Possible to save the set parameters in an external medium.

●Possible to recognize and discriminate individual information.

------------------------------ Tab3 showing ------------------------------

Order guide

Amplifiers

| Type | Appearance | Model No. | Emitting element | Control output |

|---|---|---|---|---|

| Discrete wire type |

| FX-551L3-P-C2 | Red LED | PNP open-collector transistor |

| M12 connector type |

(Note) | FX-551L3-P-J |

Note:Smartclick is a trademarks or registered trademarks of OMRON Corporation.

End plates

End plates are not supplied with the amplifier. Please order them separately when the amplifiers are mounted in cascade.

| Appearance | Model No. | Description |

|---|---|---|

| MS-DIN-E | When amplifiers are mounted in cascade, or when an amplifier moves depending on the way it is installed on a DIN rail, these end plates clamp amplifiers into place on both sides. Make sure to use end plates when cascading multiple amplifiers together. Two pcs. per set |

------------------------------ Tab4 showing ------------------------------

Option

| Designation | Model No. | Description |

|---|---|---|

| Amplifier mounting bracket | MS-DIN-2 | Mounting bracket for amplifier |

MS-DIN-2

Recommended extension cables for M12 connector type

Manufactured by OMRON Corporation

Extension cable with connectors on both ends XS5W series

※Smartclick is a trademark or registered trademark of OMRON Corporation. Contact the manufacturer for details of the recommended products.

------------------------------ Tab5 showing ------------------------------

Specifications

| Type | Discrete wire type | M12 connector type | |

|---|---|---|---|

| Model No. | FX-551L3-P-C2 | FX-551L3-P-J | |

| Applicable regulations | CE Marking (EMC Directive, RoHS Directive), UKCA Marking (EMC Regulations, RoHS Regulations) | ||

| Supply voltage | 12 to 24 V DC +10−15 % Ripple P-P 10 % or less | ||

| Power consumption | Normal operation: 960 mW or less (current consumption 40 mA or less at 24 V supply voltage) ECO mode: 720 mW or less (current consumption 30 mA or less at 24 V supply voltage) | ||

| Communication output (C/Q) (Note 2) | IO-Link communication | IO-Link Specification V1.1 | |

| Baud rate | COM3(230.4kbps) | ||

| Process data | 4byte | ||

| Minimum cycle time | 1.0ms | ||

| Control output (DO) | PNP open-collector transistor • Maximum source current: 50 mA • Applied voltage: 30 V DC or less (between output and +V) • Residual voltage: 2 V or less (Note 3) (at maximum source current) | ||

| Output operation | Switchable either Light-ON or Dark-ON by L/D mode | ||

| Short-circuit protection | Incorporated | ||

| Response time | STD: 250 μs or less, LONG: 2 ms or less, U-LG: 4 ms or less, HYPR: 24 ms or less, selectable | ||

| Sensitivity setting | 2-point teaching / Limit teaching / Full-auto teaching / Manual adjustment | ||

| Incident light sensitivity setting | Incorporated, 4 steps | ||

| Incident light intensity display range | STD: 0 to 4,000, LONG: 0 to 8,000, U-LG / HYPR: 0 to 9,999 | ||

| Timer function | Incorporated with variable OFF-delay / ON-delay / One-shot, switchable either effective or ineffective | ||

| Timer period | 0.1 to 999.9 ms approx., in units of 0.1 ms approx. | ||

| Different frequency interference prevention function (Note 4) | Incorporated (up to 4 units). Note that the response time varies depending on the setting. F-1: 0.8 ms or less, F-2: 0.9 ms or less, F-3: 1.0 ms or less, F-4: 1.7 ms or less | ||

| Protection | IP40(IEC) | ||

| Ambient temperature | -10 to +55℃ +14 to +131℉ (If 4 to 7 units are mounted in cascade: -10 to +50℃ +14 to +122℉ or if 8 to 16 units are mounted in cascade: -10 to +45℃ +14 to +113℉) (No dew condensation or icing allowed), Storage: -20 to +70℃ -4 to +158℉ | ||

| Vibration resistance | 10 to 150 Hz frequency, 0.75 mm 0.030 in double amplitude (10 G max.) in X, Y and Z directions for two hours each | ||

| Shock resistance | 98 m/s2 acceleration (10 G approx.) in X, Y and Z directions five times each | ||

| Emitting element (modulated) | Red LED (Peak emission wavelength: 660 nm 0.026 mil) | ||

| Material | Enclosure, Case cover: Polycarbonate, Switch: Polyacetal | ||

| Cable | 0.2 mm2 4-core cabtyre cable, 2 m 6.562 ft long | 0.2 mm2 cabtyre cable with M12 connector, 0.3 m 0.984 ft long | |

| Cable extension | Extension up to total 20 m 65.617 ft is possible with 0.3 mm2, or more, cable. (Condition of CE compliance: less tan 20 m 65.617 ft) (however, supply voltage 12 V DC or more) | ||

| Weight | Net weight: 55 g approx., Gross weight: 80 g approx. | Net weight: 35 g approx., Gross weight: 60 g approx. | |

Notes:

1)Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +23℃ +73.4℉.

2)When the sensor is used as an ordinary sensor, the communication output (C/Q) provides the same output operation as the control output (DO).

3)In case of using the cable (cable length 2 m 6.562 ft).

4)This function increases the hysteresis. Check the sensing condition when using the function.

------------------------------ Tab6 showing ------------------------------

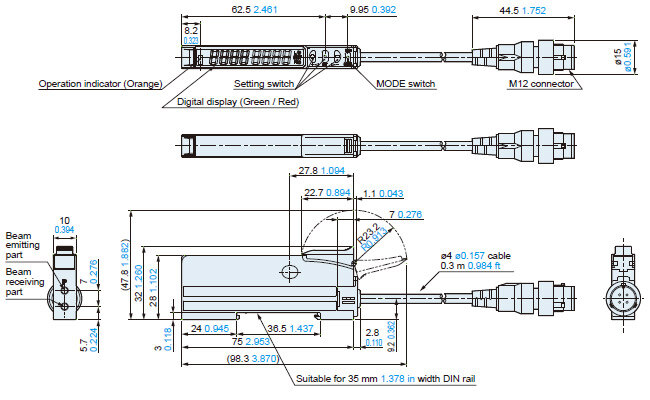

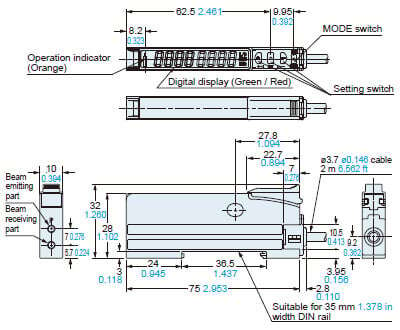

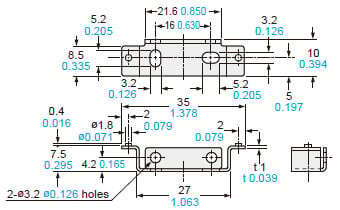

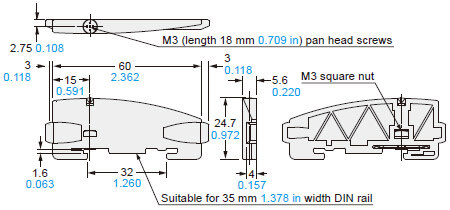

Dimensions

- Unit: mm in

FX-551L3-P-J

Amplifier

FX-551L3-P-C2

Amplifier

MS-DIN-2

Amplifier mounting bracket (Optional)

Material: Cold rolled carbon steel (SPCC) (Uni-chrome plated)

MS-DIN-E

End plate (Optional)

Material: Polycarbonate

------------------------------ Tab7 showing ------------------------------

I/O Circuit and Wiring diagrams

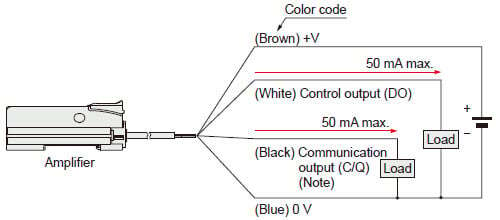

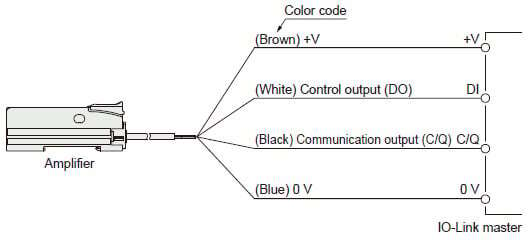

FX-551L3-P-C2

Discrete wire type

<When using as an ordinary sensor>

<When connecting to the IO-Link master>

Note:

When the sensor is used as an ordinary sensor, the communication output (C/Q) provides the same output operation as the control output (DO).

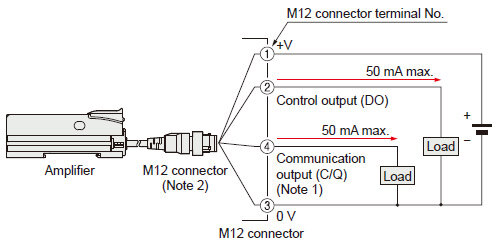

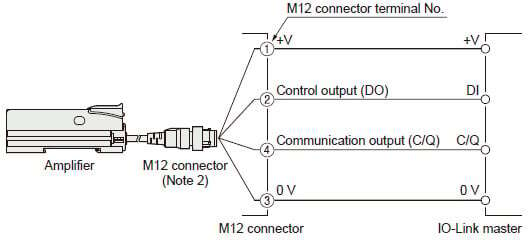

FX-551L3-P-J

M12 connector type

<When using as an ordinary sensor>

<When connecting to the IO-Link master>

Notes:

1)When the sensor is used as an ordinary sensor, the communication output (C/Q) provides the same output operation as the control output (DO).

2)When wiring with the discrete wire or extending the cable from the M12 connector, separately prepare commercially available M12 connector cable.

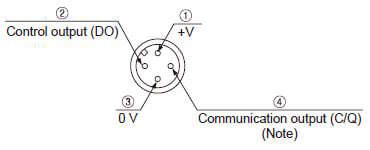

M12 connector terminal arrangement diagram

| Terminal No. | Designation |

|---|---|

| ① | +V |

| ② | Control output (DO) |

| ③ | 0V |

| ④ | Communication output (C/Q) (Note) |

Note:When the sensor is used as an ordinary sensor, the communication output (C/Q) provides the same output operation as the control output (DO).

------------------------------ Tab8 showing ------------------------------

List of fibers

Refer to "Digital Fiber Sensor FX-550 List of fibers" for the sensing range.

Note :

Both FX-551L3-P-C2 and FX-551L3-P-J can be connected to the same fibers as for the digital fiber sensor FX-550 series and provide the same sensing range. However, the FAST mode is not available.

------------------------------ Tab9 showing ------------------------------

Cautions For Use

- This website is a guide to select a suitable product.

Be sure to read instruction manual of the product prior to its use.

- Never use this product as a sensing device for personnel protection.

- In case of using sensing devices for personnel protection, use products which meet laws and standards, such as OSHA, ANSI or IEC etc., for personnel protection applicable in each region or country.

Wiring

- Make sure that the power supply is OFF while adding or removing the amplifiers.

- Note that if a voltage exceeding the rated range is applied, or if an AC power supply is directly connected, the product may get burnt or damaged.

- Note that short-circuit of the load or wrong wiring may burn or damage the product.

- Do not run the wires together with high-voltage lines or power lines, or put them in the same raceway. This can cause malfunction due to induction.

- Verify that the supply voltage variation is within the rating.

- If power is supplied from a commercial switching regulator, ensure that the frame ground (F.G.) terminal of the power supply is connected to an actual ground.

- In case noise generating equipment (switching regulator, inverter motor, etc.) is used in the vicinity of this product, connect the frame ground (F.G.) terminal of the equipment to an actual ground.

- Make sure that stress by forcible bending or pulling is not applied to the sensor cable joint and fiber cable.

Others

- This product has been developed / produced for industrial use only.

- The specification may not be satisfied in a strong magnetic field.

- The ultra long distance (U-LG, HYPR) mode is more likely to be affected by extraneous noise since the sensitivity of that is higher than the other modes. Make sure to check the environment before use.

- Do not use during the initial transient time (STD: 0.5 sec., LONG, U-LG, HYPR: 1 sec.) after the power supply is switched ON.

- These sensors are only for indoor use.

- Avoid dust, dirt, and steam.

- Make sure that the product does not come in contact with oil, grease, organic solvents such as thinner, etc., strong acid or alkaline.

- This product cannot be used in an environment containing inflammable or explosive gases.

- Never disassemble or modify this product.

- This product adopts EEPROM. Settings cannot be done a million times or more because of the EEPROM's lifetime.