停產資訊

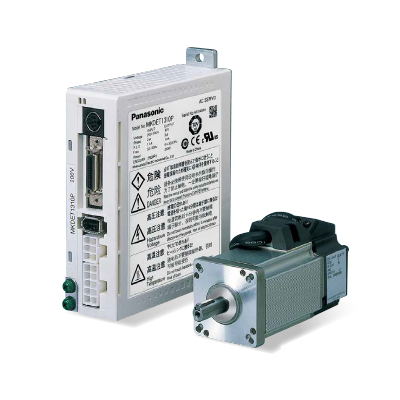

Lineup

Motor Lineup

Ultra low inertia

| Motor series | Rated output (kW) | Rated rotational speed (Max.speed) (r/min) | Rotary encoder | Brake | Gear | UL/ CSA | Enclosure | Features | |

|---|---|---|---|---|---|---|---|---|---|

| 2500 P/r incremental | 17bit absolute/ incremental | Holding | High precision | ||||||

| MUMA

| 0.05 to 0.4 0.05 0.1 0.2 0.4 | 3000 (5000) | ○ | — | ○ | ○ | ○ | IP65 Except shaft throughhole and connector | Small capacity Ultra low inertia |

Driver Lineup

| Series | Control method | Interface | Safety Function |

|---|---|---|---|

| E Series

| Position control | Pulse input | without |

System Configuration

Wiring of main circuit

List of recommended peripheral devices

| Power supply | Motor | Power capacity (at rated output ) | Circuit Breaker (Rated current) | Noise Filter | Magnetic Contactor (Contact Composition) | Wire diameter (L1,L2,L3,U,V and W) | |

|---|---|---|---|---|---|---|---|

| Series | Output | ||||||

| Single phase, 100 V | MUMA | 50 W | 0.3 kVA | 5 A | DV0P4160 | 10 A (3P+1a) | 0.75 mm2 to 0.85 mm2 AWG18 |

| 100 W | 0.4 kVA | ||||||

| 200 W | 0.5 kVA | 10 A | |||||

| Single phase, 200 V | 50 W | 0.3 kVA | 5 A | 15 A (3P+1a) | |||

| 100 W | |||||||

| 200 W | 0.5 kVA | ||||||

| 400 W | 0.9 kVA | 10 A | |||||

| 3-phase 200 V | 50 W | 0.3 kVA | 5 A | 10 A (3P+1a) | |||

| 100 W | |||||||

| 200 W | 0.5 kVA | ||||||

| 400 W | 0.9 kVA | 10 A | |||||

* Select the single and 3-phase common specifications corresponding to the power supplies.

To conform to EC Directives, install a circuit breaker which conforms to IEC and UL Standards (Listed,  marked) between noise filter and power supply.

marked) between noise filter and power supply.

Remarks

- Use a copper conductor cables with temperature rating of 60 °C or higher for main power connector and ground terminal wiring.

- Use a cable for ground with diameter of 2.0 mm2 (AWG14) or larger.

Driver Specifications

Basic Specifications

| Item | Specifications | |

|---|---|---|

| Input power | Single phase, 100 V | Single phase, 100 V (+10 % -15 %) to 115 V (+10 % -15 %) 50 Hz / 60 Hz |

| Single phase, 200 V | Single phase, 200 V (+10 % -15 %) to 240 V (+10 % -15 %) 50 Hz / 60 Hz | |

| 3-phase, 200 V | 3-phase, 200 V (+10 % -15 %) to 240 V (+10 % -15 %) 50 Hz / 60 Hz | |

| Environment | Temperature | Operating : 0 °C to 55 °C, Storage : –20 °C to 65 °C (Max.temperature guarantee 80 °C for 72 hours [Nomal temperature]) |

| Humidity | Both operating and storage : 90 %RH or less (free from condensation) | |

| Altitude | 1000 m or lower | |

| Vibration | 5.88 m/s2 or less, 10 Hz to 60 Hz (No continuous use at resonance frequency) | |

| Withstand voltage | Should be 1500 VAC (Sensed current: 20 mA) for 1 minute between Primary and Ground. | |

| Control method | IGBT PWM Sinusoidal wave drive | |

| Encoder feedback | 2500 P/r (10000 resolution) incremental encoder | |

| Control signal | Input | 7 inputs (1) Servo-ON, (2) Alarm clear and other inputs vary depending on the control mode. |

| Output | 4 outputs (1) Servo alarm, (2) Alarm, (3) Release signal of external brake and other outputs vary depending on the control mode. | |

| Pulse signal | Input | 2 inputs Supports both line driver I/F and open collector I/F. |

| Output | 4 outputs Feed out the encoder pulse (A, B and Z-phase) in line driver. Z-phase pulse is also feed out in open collector. | |

| Communication function | RS232 | 1 : 1 communication to a host with RS232 interface is enabled. |

| Display LED | (1) Status LED (STATUS), (2) Alarm code LED (ALM-CODE) | |

| Regeneration | No built-in regenerative resistor (external resistor only) | |

| Dynamic brake | Built-in | |

| Control mode | 3 modes of (1) High-speed position control, (2) Internal velocity control and (3) High-functionality positioning control are selectable with parameter. | |

Functions

| Item | Specifications | ||

|---|---|---|---|

| Position control | Control input | (1) CW over-travel inhibition, (2) CCW over-travel inhibition, (3) Deviation counter clear, (4) Gain switching, (5) Electronic gear switching | |

| Control output | (1) Positioning complete (In-position) | ||

| Pulse input | Max. command pulse frequency | Line driver : 500 kpps, Open collector : 200 kpps | |

| Type of input pulse train | Differential input. Selectable with parameter, ((1) CW/CCW, (2) A and B-phase, (3) Command and Direction) | ||

| Electronic gear (Division/Multiplication of command pulse ) | Setup of electronic gear ratio Setup range of (1-10000) × 2(0-17)/(1-10000) | ||

| Smoothing filter | Primary delay filter or FIR type filter is selectable to the command input. | ||

| Internal speed control | Control input | (1) CW over-travel inhibition, (2) CCW over-travel inhibition, (3) Selection 1 of internal command speed, (4) Selection 2 of internal command speed, (5) Speed zero clamp | |

| Control output | (1) Speed arrival (at-speed) | ||

| Internal speed command | Internal 4-speed is selectable with control input. | ||

| Soft-start/down function | Individual setup of acceleration and deceleration are enabled, with 0 s to 10 s/1000 r/min. Sigmoid acceleration/deceleration is also enabled. | ||

| Zero-speed clamp | 0-clamp of internal speed command with speed zero clamp input is enabled. | ||

| Common | Auto-gain tuning | Real-time | Estimates the load inertia in real-time in actual operation and sets up the gain automatically corresponding to the machine stiffness. Useable at (1) High-response position control, (2) Internal speed control and (3) High-functionality position control. |

| Normal mode | Estimates the load inertia with an action command inside of the driver, and sets up the gain automatically corresponding to setup of the machine stiffness. Useable at (1) High-response position control, (2) Internal speed control and (3) High-functionality position control. | ||

| Masking of unnecessary input | Masking of the following input signal is enabled. (1) Over-travel inhibition, (2) Speed zero clamp, (3) Torque limit switching | ||

| Division of encoder feedback pulse | 1 P/r to 2500 P/r (encoder pulses count is the max.). | ||

| Protective function | Hardware error | Over-voltage, under-voltage, over-speed over-load, over-heat, over-current and encoder error etc. | |

| Software error | Excess position deviation, command pulse division error, EEPROM error etc. | ||

| Traceability of alarm data | Traceable up to past 14 alarms including the present one. | ||

| Damping control function | Manual setup with parameter | ||

| Setup | Manual | Console | |

| Setup support software | PANATERM (Supporting OS : Windows98, Windows ME, Windows2000, and WindowsXP) | ||

Wiring/ Connection

- 1.Standard Wiring Example of Main Circuit/ Driver Specifications Encorder Wiring Diagram

- 2.Control Circuit Standard Wiring Example

1. Standard Wiring Example of Main Circuit/ Driver Specifications Encorder Wiring Diagram

Standard Wiring Example of Main Circuit

When you make your own junction cable for encoder

1) Refer the wiring diagram.

2) Use the twisted pair wire with shield, with core diameter of 0.18 mm2 (AWG24) or larger, with higher bending resistance.

3) Use the twisted pair wire for the corresponding signal and power supply.

4) Shielding

- Connect the shield of the driver to the case of CN X4.

- Connect the shield of the motor to Pin-6.

2. Control Circuit Standard Wiring Example

Fig. 1

Fig. 1

- This fig. shows the usage of an external control signal power supply.

- You need to install an resistor R for current limit corresponding to VDC.

Option

You can search for options by category.

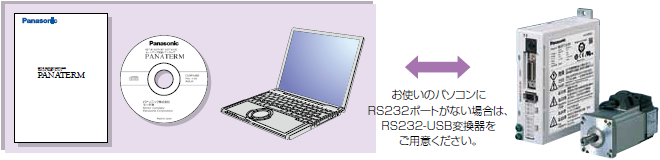

Software

Option

Setup Support Software “PANATERM” for MINAS series AC Servo Motor & Driver

Part No. DV0P4460 (Japanese/English version)

- Can not use with A5, A6 family.

The PANATERM assists users in setting parameters, monitoring control conditions, setup support, and analyzing mechanical operation data on the PC screen, when installed in a commercially available personal computer, and connected to the MINAS A4 series, E series through the RS232 serial interface.

For using this software, separately sold PC communication cable (Part No. DV0P1960) is required.

When your PC is not equipped with RS232 I/F (D-sub connector 9-pins), please prepare RS232 (D-sub connector 9-pins)-USB converter.

Basic Function

●Parameter setup

- After a parameter is defined on the screen, it will be sent to the driver immediately.

- Once you register parameters you frequently use, they can be easily set up on the screen.

Monitoring Control Conditions

●Monitor

- Control conditions: Control mode, velocity, torque, error and warning

- Driver input signal

・Load conditions: Total count of command/feedback pulses, Load ratio, Regenerative resistor load ratio

●Alarm

- Displays the numbers and contents of the current alarm and up to 14 error events in the past.

- Clears the numbers and contents of the current alarm and up to 14 error events in the past.

Setup

●Auto tuning

- Gain adjustment and inertia ratio measurement

●Graphic waveform display

- The graphic display shows command velocity, actual velocity, torque, and error waveforms.

●Absolute encoder setup

- Clears absolute encoder at the origin.

- Displays single revolution/multi-revolution data.

- Displays absolute encoder status.

Analysis of Mechanical Operation Data

●Frequency analysis

- Measures frequency characteristics of the machine, and displays Bode diagram.

Hardware configuration

[Personal computer]

- CPU : Pentium 100MHz or more

- Memory : 16 MB or more (32 MB recommended)

- Hard disk capacity (vacancy of 25 MB or more recommended)

- OS : Windows® 98, Windows® Me, Windows® 2000, Windows® XP (US version)

- Communication speed of serial communication port : 2400 bps or more (The software may not operate normally using USB-to-Serial adapter.)

[Display]

- Resolution : 640*480 (VGA) or more (desirably 1024*768)

- Number of colors : 256 colors or more

[CD-ROM drive]

CD-ROM drive operable on the above-mentioned personal computer