Compact Type 4 Safety Beam Sensor ST4

Download

-

Basic Information

-

Application

-

Order guide

-

Option

-

Specifications

-

Dimensions

-

Circuit/ Wiring

-

Cautions For Use

Basic Information

From wide areas to narrow spaces, full support for both safety and productivity!

CE :Machinery Directive, EMC Directive

UKCA :Machinery Regulations, EMC Regulations

-

The control category differs depending on the configuration and wiring of the external circuit.

Features

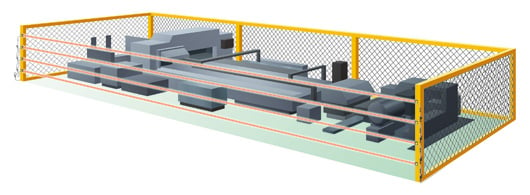

Long sensing range of up to 15 m 49.213 ft [Sensor head]

Secures safety of large facilities where installation of guardian fence is difficult.

Series connection of sensors and interference prevention [Sensor head]

The numbers of sensor heads and controllers can be freely adjusted to meet the heights and the required numbers of the protection area.

![Series connection of sensors and interference prevention [Sensor head]](https://tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/safety/st4/images/pic03.jpg)

Beam axis alignment and operation confirmation [Sensor head]

The beam interruption indicator is incorporated in both the emitter and receiver. This indicator can be used not only for operation confirmation but also for beam axis alignment. Moreover, the stability indicator indicates if the incident light intensity exceeds 150 % in stable operation.

![Beam axis alignment and operation confirmation [Sensor head]](https://tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/safety/st4/images/pic04.jpg)

Supports beam axis alignment at startup and quick restoration in case of trouble [High-functional type ST4-C12EX]

Light received condition of the sensor heads in series connection can be confirmed by the high-functional controller ST4-C12EX.

In addition, any abnormal sensors during lockout can be identified.

![Supports beam axis alignment at startup and quick restoration in case of trouble [High-functional type ST4-C12EX]](https://tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/safety/st4/images/pic05.jpg)

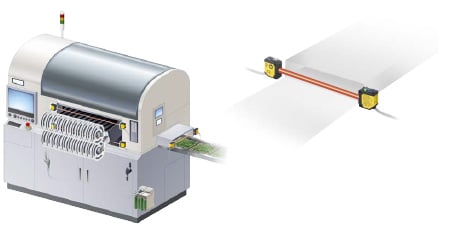

In small openings where safety light curtains cannot be installed

Ensures safety in small openings that are often missed.

Compact sensor head saves space

The Type 4 long sensing range type has a compact size that is equivalent to those of general-purpose photoelectric sensors.

Industry standard mounting pitch [Sensor head]

Having the same mounting pitch as those of general-purpose photoelectric sensors makes model switchovers easy.

![Industry standard mounting pitch [Sensor head]](https://tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/safety/st4/images/pic08.jpg)

Waterproof IP67

Conforming to IP67 rating, the sensor heads can be used safely even at lines where water splashes during washing.

![Protection structure IP67 [Sensor head]](https://tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/safety/st4/images/pic09.jpg)

Control of interferences to surrounding sensors [Sensor head]

The emission amount adjuster can be used to reduce the emission to control any interference to the surrounding sensors.

![Control of interferences to surrounding sensors [Sensor head]](https://tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/safety/st4/images/pic10.jpg)

Supports both PNP and NPN polarities [Controller]

A single unit can be used for PNP / NPN output switching, reducing the number of parts that need to be registered.

![Supports both PNP and NPN polarities [Controller]](https://tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/safety/st4/images/pic11.jpg)

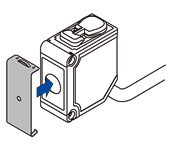

Easy connector connection [Controller]

Connecting to the sensor head is done using connector connections, which shortens setup and replacement time.

![Easy connector connection [Controller]](https://tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/safety/st4/images/pic12.jpg)

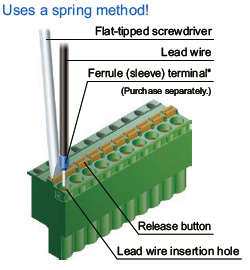

Easy setup requiring no torque control

A spring method is used for the terminal blocks. There is no need to control tightening torques for these terminal blocks.

Connection is possible with a single wire or coil wires.

Removal terminal blocks reduce maintenance time

The work required for reconnecting wiring during maintenance is reduced.

Semiconductor output reduces running costs! [Controller]

Semiconductor output is used for control output. This means there is no need to periodically replace safety relays.

![Semiconductor output reduces running costs! [Controller]](https://tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/safety/st4/images/pic15.jpg)

Error details can be understood at a glance! [High-functional type ST4-C12EX]

If a problem should occur, the control output is switched OFF, and the details of the error appear on the digital display.

![Error details can be understood at a glance! [High-functional type ST4-C12EX]](https://tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/safety/st4/images/pic16.jpg)

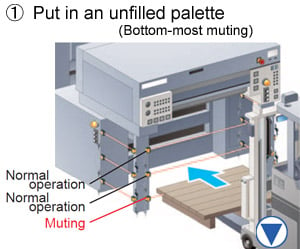

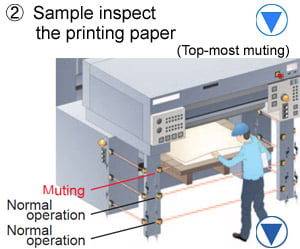

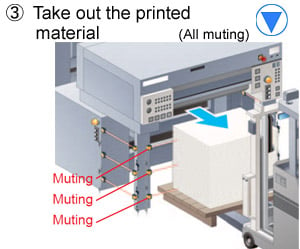

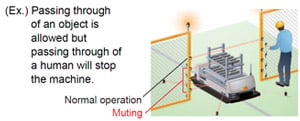

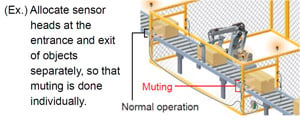

Three patterns of muting control function for greater safety with no loss in productivity [High-functional type ST4-C12EX]

Sensor heads, muting sensors, and muting lamps connect directly to the controller, so that muting control circuits can be built easily.

![Three patterns of muting control function for greater safety with no loss in productivity [High-functional type ST4-C12EX]](https://tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/safety/st4/images/pic17.jpg)

![Three patterns of muting control function for greater safety with no loss in productivity [High-functional type ST4-C12EX]](https://tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/safety/st4/images/pic18.jpg)

Muting pattern No.1 Compliant to international safety standard ISO 12643 for printing industry Muting area can be changed to suit the printing process. This is the optimal muting control for printing machines.

Muting pattern No.2

Set apart only the top-most sensor heads and perform muting control.

Muting pattern No.3

Divide the muting area into two.

Line restarts smoothly after being stopped while muting control was active <Override function> [High-functional type ST4-C12EX]

In case the sensor head has been interrupted by an object or in case there is an emergency stop before the muting conditions have been established, all the sensor heads will be temporarily deactivated following by a smooth restart.

![Line restarts smoothly after being stopped while muting control was active <Override function> [High-functional type ST4-C12EX]](https://tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/safety/st4/images/pic24.jpg)

Informs all kinds of operation conditions [High-functional type ST4-C12EX]

In case the muting lamp that is connected to the controller breaks, an alarm will go off. Also, auxiliary outputs that link to the muting function, override function, and control outputs (OSSD) are incorporated.

| Auxiliary outputs | Function | Operation |

|---|---|---|

| Auxiliary output 1 | Muting output | ON when muting function is invalid |

| Auxiliary output 2 | Override output | ON when override function is invalid |

| Auxiliary output 3 | Blown lamp output | ON when muting lamp is in normal condition |

| Auxiliary output 4 | Monitor output | ON when control output is OFF |

Applications

Order guide

Sensor heads

Always use the sensor head and the controller together as a set.

| Type | Appearance | Operating range (Note 1) | Model No. (Note 2) | |

|---|---|---|---|---|

| Cable length 0.2 m 0.656 ft |

| 0.1 to 15 m 0.328 to 49.231 ft | ST4-A1-J02 | |

| With emission amount adjuster | ST4-A1-J02V | |||

| Cable length 1 m 3.281 ft | ST4-A1-J1 | |||

| With emission amount adjuster | ST4-A1-J1V | |||

Note 1 : The "operating range" is the possible setting distance between the emitter and the receiver.

Note 2 : The model No. with suffix "E" shown on the label affixed to the product is the emitter, "D" shown on the label is the receiver.

Controllers

Always use the sensor head and the controller together as a set.

Option

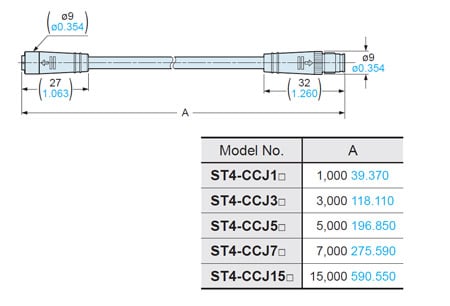

| Designation | Model No. | Description | ||

|---|---|---|---|---|

| Extension cable | ST4-CCJ1E | Cable length: 1 m 3.281 ft Net weight 55 g approx. (1 cable) | For emitter | Use as an extension for the ST4-A□. 5-wire shielded cable. One each for emitter and receiver Cable color: Gray (for emitter), Gray with black line (for receiver) Connector color: Gray (for emitter), Black (for receiver) Min. bending radius: R5 mm R0.197 in |

| ST4-CCJ1D | For receiver | |||

| ST4-CCJ3E | Cable length: 3 m 9.843 ft Net weight 130 g approx. (1 cable) | For emitter | ||

| ST4-CCJ3D | For receiver | |||

| ST4-CCJ5E | Cable length: 5 m 16.404 ft Net weight 200 g approx. (1 cable) | For emitter | ||

| ST4-CCJ5D | For receiver | |||

| ST4-CCJ7E | Cable length: 7 m 22.966 ft Net weight 270 g approx. (1 cable) | For emitter | ||

| ST4-CCJ7D | For receiver | |||

| ST4-CCJ15E | Cable length: 15 m 49.213 ft Net weight 540 g approx. (1 cable) | For emitter | ||

| ST4-CCJ15D | For receiver | |||

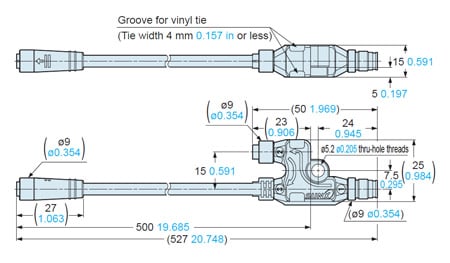

| Branch cable | ST4-CCJ05-WY | Cable length: 0.5 m 1.640 ft Net weight 80 g approx. (2 cables) | Use to connect ST4-A□ in series. 5-wire shielded cable. Two cables per set for emitter and receiver Cable color: Gray (for emitter), Gray with black line (for receiver) Connector color: Gray (for emitter), Black (for receiver) Min. bending radius: R5 mm R0.197 in | |

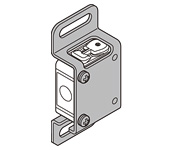

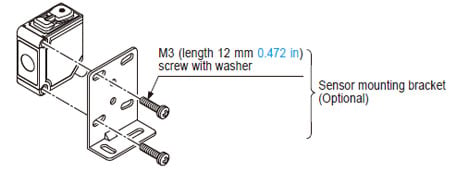

| Sensor head mounting bracket | MS-CX-1 | Foot angled mounting bracket. 2 different types for emitter and receiver required. | ||

| MS-ST4-3 | Back angled mounting bracket. 2 different types for emitter and receiver required. | |||

| MS-ST4-6 | Foot biangled mounting bracket. 2 different types for emitter and receiver required. | |||

| Round slit mask (Note) | OS-ST4-2 (Slit size ø2mm ø0.079 in) | Dampens the light to suppress interference with neighboring sensors. | Operating range Slit on one side: 3 m 9.843 ft Slit on both sides: 0.75 m 2.461 ft | |

| OS-ST4-3 (Slit size ø3mm ø0.118 in) | Operating range Slit on one side: 4.5 m 14.764 ft Slit on both sides: 1.5 m 4.921 ft | |||

Note : When the slit mask is installed, applicable sensing objects are opaque objects with a diameter of ø9 mm ø0.354 in or more.

Extension cable

ST4-CCJ□

Branch cable

ST4-CCJ05-WY

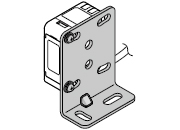

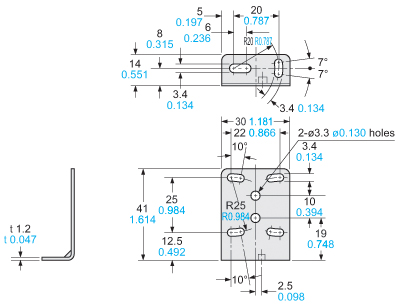

Sensor mounting bracket

MS-CX-1

Two M3 (length 12 mm 0.472 in)screws with washers are attached.

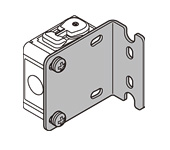

MS-ST4-3

Two M3 (length 12 mm 0.472 in)screws with washers are attached.

MS-ST4-6

Two M3 (length 12 mm 0.472 in)screws with washers are attached.

Round slit mask

OS-ST4-2

OS-ST4-3

Specifications

Sensor heads

| Type | Cable length 0.2 m 0.656 ft | Cable length 1 m 3.281 ft | ||

|---|---|---|---|---|

| With emission amount adjuster | With emission amount adjuster | |||

| Model No. | ST4-A1-J02 | ST4-A1-J02V | ST4-A1-J1 | ST4-A1-J1V |

| Applicable standard (Note 2) | IEC 61496-1/2 (JIS B 9704-1/2 / ANSI/UL 61496-1/2) (Type 4), ISO 13849-1:2015 (Category 4, PLe), JIS B 9705-1 (Category 4), IEC 61508-1 to 3 (SIL3), IEC 62061 (SIL3), JIS C 0508-1 to 3 (SIL3), UL 1998, OSHA 1910.212, OSHA 1910.217 (C), ANSI B11.1 to B11.19, ANSI/RIA R15.06, ANSI/ISA S84.01 (SIL3) | |||

| Applicable regulations and certifications (Note 2) | CE Marking (Machinery Directive, EMC Directive, RoHS Directive) , UKCA Marking [Supply of Machinery (Safety) Regulations, EMC Regulations, RoHS Regulations], UL/c-UL Listing certification, TÜV SÜD certification | |||

| Operating range | 0.1 to 15 m 0.328 to 49.213 ft (Note 3) | |||

| Sensing object | ø9 mm ø0.354 in or more opaque object | |||

| Effective aperture angle (EAA) | ±2.5° or less for operating range exceeding 3 m 9.843 ft (required by IEC 61496-2 / UL 61496-2) | |||

| Supply voltage | Supplied from controller | |||

| Current consumption | Emitter: 11 mA or less, Receiver: 9 mA or less | |||

| Beam interruption indicator (Note 4) | Red LED (lights up when the beam is interrupted or lock out, lights off during reception) | |||

| Beam emission indicator | Green LED (lights up during beam emission, lights off during emission halt) | |||

| Stable incident beam indicator | Green LED (lights up under stable light received condition, lights off under unstable light received condition) | |||

| Degree of protection | IP67 (IEC) | |||

| Ambient temperature | −10 to +55 ℃ +14 to +131 ℉ (No dew condensation or icing allowed), Storage: −25 to +70 ℃ −13 to +158 ℉ | |||

| Ambient humidity | 30 to 85 % RH, Storage: 30 to 95 % RH | |||

| Ambient illuminance | Incandescent lamp: 3,500 Lx or less at the light-receiving face | |||

| Voltage withstandability | 1,000 V AC for one min. between all supply terminals connected together and enclosure | |||

| Insulation resistance | 20 MΩ or more with 500V DC megger between all supply terminals connected together and enclosure | |||

| Vibration resistance | 10 to 55 Hz frequency, 0.75 mm 0.030 in double amplitude or maximum acceleration 90 m/s2 in X, Y and Z directions for two hours each | |||

| Shock resistance | 300 m/s2 acceleration in X, Y and Z directions three times each | |||

| Emitting element | Infrared LED (Peak emission wavelength: 870 nm 0.034 mil) | |||

| Material | Enclosure: PBT (Polybutylene terephthalate), Lens: Acrylic, Indicator cover: Acrylic | |||

| Cable | Shielded cable with connector, 0.2 m 0.656 ft long | Shielded cable with connector, 1 m 3.281 ft long | ||

| Cable extension | Extention up to total 50 m 164.042 ft is possible for both emitter and receiver with exclusive cable. | |||

| Weight (Total of emitter and receiver) | Net weight: 45 g approx. Gross weight: 60 g approx. | Net weight: 100 g approx. Gross weight: 140 g approx. | ||

Notes:

1) Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +20℃ +68℉.

2) Complies with those standards and regulations only when the sensor head is used in combination with the controller ST4-C11 / ST4-C12EX.

3) The operating range is the possible setting distance between the emitter and the receiver. It can detect sensing object of less than 0.1 m 0.328 ft away.

4) Shows light interruption information between the emitter and the receiver with the same address. It does not show OSSD output.

For details on addresses, refer to "Address allocations of sensor head ST4-A□".

Controllers

| Type | Controller | High-functional controller | |

|---|---|---|---|

| Model No. | ST4-C11 | ST4-C12EX | |

| Applicable sensor head | ST4-A□ | ||

| No. of series connections | Interference prevention possible when up to a maximum of 6 sets are connected (When the maximum of 3 controllers are connected together, interference prevention is possible for up to 18 sets) | ||

| Applicable standards (Note 2) | IEC 61496-1/2 (JIS B 9704-1/2 / ANSI/UL 61496-1/2) (Type 4), ISO 13849-1:2015 (Category 4, PLe), JIS B 9705-1 (Category 4), IEC 61508-1 to 3 (SIL3), IEC 62061 (SILCL3), JIS C 0508-1 to 3 (SIL3), UL 1998, OSHA 1910.212, OSHA 1910.217 (C), ANSI B11.1 to B11.19, ANSI/RIA R15.06, ANSI/ISA S84.01 (SIL3) | ||

| Applicable regulations and certifications (Note 2) | CE Marking (Machinery Directive, EMC Directive, RoHS Directive) , UKCA Marking [Supply of Machinery (Safety) Regulations, EMC Regulations, RoHS Regulations], UL/c-UL Listing certification, TÜV SÜD certification | ||

| Supply voltage | 24 V DC +10−15 % Ripple P-P 10 % or less | ||

| Current consumption | 100 mA or less (excluding sensor head ST4-A□) | 120 mA or less (excluding sensor head ST4-A□) | |

| Control outputs (OSSD1, OSSD2) (Note 3) | PNP open-collector transistor / NPN open-collector transistor, Dual output x 1 system (Set using output polarity selection switch) <PNP output> • Maximum source current: 200 mA • Applied voltage: same as the supply voltage (between control output and +V) • Residual voltage: 2.5 V or less (at 200 mA source current) • Leakage current: 200 μA or less (including power OFF condition) • Maximum load capacity: 1 μF (from no-load to max. source current) • Load wiring resistance: 3 Ω or less (between control output and load) <NPN output> • Maximum sink current: 200 mA • Applied voltage: same as the supply voltage (between control output and 0 V) • Residual voltage: 2.0 V or less (at 200 mA sink current) • Leakage current: 200 μA or less (including power OFF condition) • Maximum load capacity: 1 μF (from no-load to max. sink current) • Load wiring resistance: 3 Ω or less (between control output and load) | ||

| Operation mode | ON when all beams of the connected ST4-A□s are received OFF when one or more beams of the connected ST4-A□s are interrupted (except during muting / override when ST4-C12EX is used) OFF during lockout | ||

| Protection circuit | Incorporated | ||

| Response time | OFF response: 25 ms or less, ON response: 90 ms or less (auto reset) / 140 ms or less (manual reset) | ||

| Auxiliary outputs (Note 3) | PNP open-collector transistor / NPN open-collector transistor (Set using output polarity selection switch) ST4-C11: one output ST4-C12EX: four outputs <PNP output> • Maximum source current: 100 mA • Applied voltage: same as the supply voltage (between auxiliary output and +V) • Residual voltage: 2.5 V or less (at 100 mA source current) <NPN output> • Maximum sink current: 100 mA • Applied voltage: same as the supply voltage (between auxiliary output and 0 V) • Residual voltage: 2.0 V or less (at 100 mA sink current) | ||

| Operation mode | OFF when all beams of the connected ST4-A□s are received ON when one or more beams of the connected ST4-A□s are interrupted | <Auxiliary output 1> ON when muting function is invalid OFF when muting function is valid <Auxiliary output 2> ON when override function is invalid OFF when override function is valid <Auxiliary output 3> ON when muting lamp is in normal condition OFF when muting lamp is in abnormal condition <Auxiliary output 4> Negative logic of the control outputs (OSSD1, OSSD2) | |

| Protection circuit | Incorporated | ||

| Muting lamp output (Note 3) | - | Available muting lamp: 24 V DC, 1 to 10 W | |

| Protection circuit | Incorporated | ||

| PFHD (Note 4) / MTTFD (Note 5) | Refer to the following table / More than 100 years | ||

| Degree of protection | Enclosure: IP40 (IEC), Terminal: IP20 (IEC) | ||

| Ambient temperature | −10 to +55 ℃ +14 to +131 ℉ (No dew condensation or icing allowed) Storage: −25 to +70 ℃ −13 to +158 ℉ | ||

| Ambient humidity | 30 to 85 % RH, Storage: 30 to 95 % RH | ||

| Voltage withstandability | 1,000 V AC for one min. between all supply terminals connected together and enclosure | ||

| Insulation resistance | 20 MΩ or more with 500 V DC mega between all supply terminals connected together and enclosure | ||

| Vibration resistance | 10 to 55 Hz frequency, 0.75 mm 0.030 in double amplitude maximum acceleration 90 m/s2 in X, Y and Z directions for two hours each | ||

| Shock resistance | 300 m/s2 acceleration in X, Y and Z directions three times each | ||

| Connection terminal | Detachable spring-cage terminal | ||

| Wiring cable | Terminal block connector: 0.2 to 1.5 mm2 Power supply connector (A1, A2): 0.2 to 2.5 mm2 (only for ST4-C12EX) | ||

| Material | Enclosure: ABS | ||

| Weight | Net weight: 180 g approx. Gross weight: 390 g approx. | Net weight: 240 g approx. Gross weight: 450 g approx. | |

Notes:

1) Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +20℃ +68℉.

2) Complies with those standards and regulations only when the controller is used in combination with the sensor head ST4-□.

3) If the total current of the control outputs (OSSD1, OSSD2), auxiliary outputs, and muting lamp output exceeds 400 mA, the wiring resistance between the controller and the power supply should be 1 Ω or less. In addition, if the total current is 400 mA or less, the wiring resistance between the controller and the power supply should be 2 Ω or less.

4) PFHD (Probability of dangerous failure per hour) depends on number of single beam sensor ST4-A□ connected to controller.

| Number of single beam sensor ST4-A□ | |||||||

|---|---|---|---|---|---|---|---|

| 1 unit | 2 units | 3 units | 4 units | 5 units | 6 units | ||

| PFHD | ST4-C11 | 4.79 × 10−10 | 6.53 × 10−10 | 8.27 × 10−10 | 1.00 × 10−9 | 1.18 × 10−9 | 1.35 × 10−9 |

| ST4-C12EX | 4.96 × 10−10 | 6.70 × 10−10 | 8.45 × 10−10 | 1.02 × 10−9 | 1.19 × 10−9 | 1.37 × 10−9 | |

5) MTTFD Mean time to dangerous failure (in years)

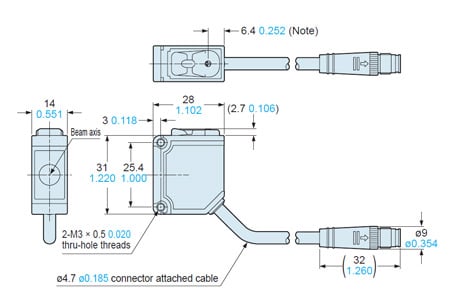

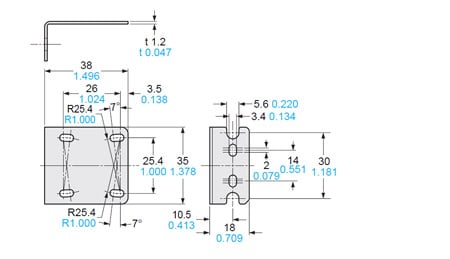

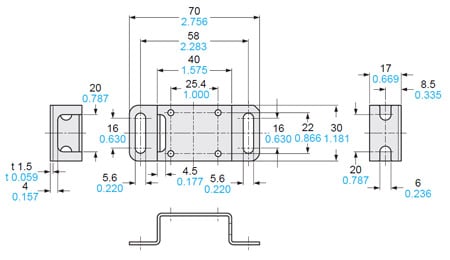

Dimensions

- Unit: mm in

ST4-A□

Sensor head

Note:It indicates the position of the emission amount adjuster on ST4-A□V.

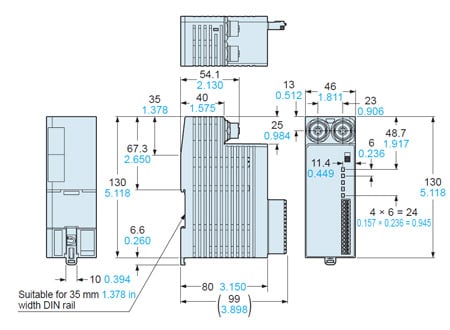

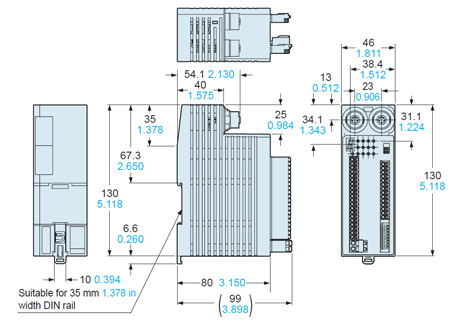

ST4-C11

Controller

ST4-C12EX

Controller

ST4-CCJ□

Extension cable (Optional)

ST4-CCJ05-WY

Branch cable (Optional)

MS-CX-1

Sensor head mounting bracket (Optional)

Material:

Stainless steel (SUS304)

Two M3 (length 12 mm 0.472 in) screws with washers are attached.

MS-ST4-3

Sensor head mounting bracket (Optional)

Material:

Stainless steel (SUS304)

Two M3 (length 12 mm 0.472 in) screws with washers are attached.

MS-ST4-6

Sensor head mounting bracket (Optional)

Material:

Stainless steel (SUS304)

Two M3 (length 12 mm 0.472 in) screws with washers are attached.

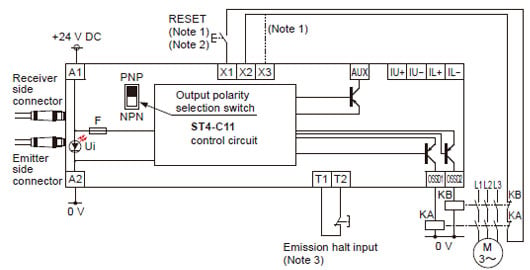

I/O Circuit and Wiring diagrams

ST4-C11

In case of PNP output

・Set the output polarity selection switch to the PNP side.

Notes:

1) The left diagram is when using manual reset. If automatic reset is used, disconnect the lead from X2 and connect it to X3. In this case, a reset (RESET) button is not needed.

2) Use a momentary-type switch as the reset (RESET) button.

3) Emission halt input is for stopping emission when open, and emitting when short-circuited. If not using the test button, short-circuit T1 and T2.

KA, KB: Force-guided relay or magnetic contactor

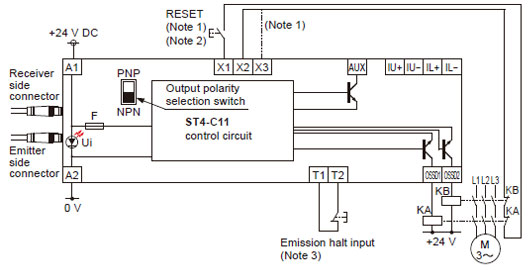

In case of NPN output

・Set the output polarity selection switch to the NPN side.

Notes:

1) The left diagram is when using manual reset. If automatic reset is used, disconnect the lead from X2 and connect it to X3. In this case, a reset (RESET) button is not needed.

2) Use a momentary-type switch as the reset (RESET) button.

3) Emission halt input is for stopping emission when open, and emitting when short-circuited. If not using the test button, short-circuit T1 and T2.

KA, KB: Force-guided relay or magnetic contactor

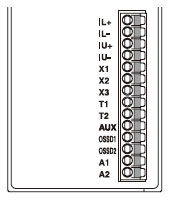

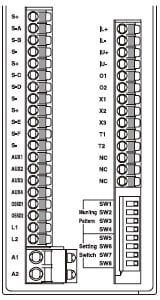

Terminal arrangement diagram

| Terminal | Description |

|---|---|

| IL+ | Interference prevention terminals For details, refer to "Interference prevention function" |

| IL- | |

| IU+ | Interference prevention terminals For details, refer to "Interference prevention function" |

| IU- | |

| X1 | Reset input terminals (When X1 and X2 are connected: manual reset, and when X1 and X3 are connected: auto reset) |

| X2 | |

| X3 | |

| T1 | Emission halt input terminals (Open: emission halt, Short-circuit: emission) |

| T2 | |

| AUX | Negative logic of the control outputs (OSSD1, OSSD2) |

| OSSD1 | Control outputs (OSSD1, OSSD2) |

| OSSD2 | |

| A1 | 24V DC |

| A2 | 0V |

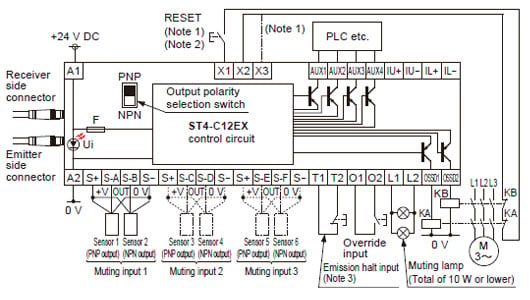

ST4-C12EX

In case of PNP output

・Set the output polarity selection switch to the PNP side.

Notes:

1) The left diagram is when using manual reset. If automatic reset is used, disconnect the lead from X2 and connect it to X3. In this case, a reset (RESET) button is not needed.

2) Use a momentary-type switch as the reset (RESET) button.

3) Emission halt input is for stopping emission when open, and emitting when short-circuited. If not using the test button, short-circuit T1 and T2.

KA, KB: Force-guided relay or magnetic contactor

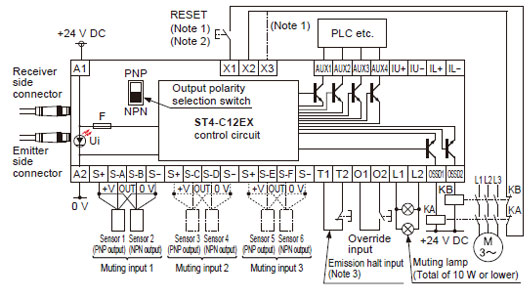

In case of NPN output

・Set the output polarity selection switch to the NPN side.

Notes:

1) The left diagram is when using manual reset. If automatic reset is used, disconnect the lead from X2 and connect it to X3. In this case, a reset (RESET) button is not needed.

2) Use a momentary-type switch as the reset (RESET) button.

3) Emission halt input is for stopping emission when open, and emitting when short-circuited. If not using the test button, short-circuit T1 and T2.

KA, KB: Force-guided relay or magnetic contactor

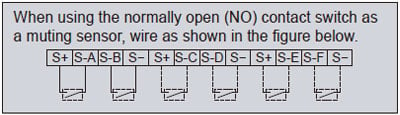

Terminal arrangement diagram

| Terminal | Description |

|---|---|

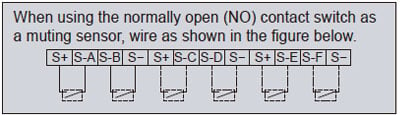

| S+ | Muting input power supply (24 V) |

| S-A | Muting input S-A [For NO (nomally open) contact or PNP output type sensor] |

| S-B | Muting input S-B [For NO (nomally open) contact or NPN output type sensor] |

| S- | Muting input power supply (0 V) |

| S+ | Muting input power supply (24 V) |

| S-C | Muting input S-C [For NO (nomally open) contact or PNP output type sensor] |

| S-D | Muting input S-D [For NO (nomally open) contact or NPN output type sensor] |

| S- | Muting input power supply (0 V) |

| S+ | Muting input power supply (24 V) |

| S-E | Muting input S-E [For NO (nomally open) contact or PNP output type sensor] |

| S-F | Muting input S-F [For NO (nomally open) contact or NPN output type sensor] |

| S- | Muting input power supply (0 V) |

| AUX1 | Auxiliary output 1 (muting function) |

| AUX2 | Auxiliary output 2 (override function) |

| AUX3 | Auxiliary output 3 (muting lamp shutoff) |

| AUX4 | Negative logic of the control outputs (OSSD1, OSSD2) |

| OSSD1 | Control outputs (OSSD1, OSSD2) |

| OSSD2 | |

| L1 | Muting lamp connecting terminal |

| L2 | |

| A1 | 24V DC |

| A2 | 0V |

| IL+ | Interference prevention terminals For details, refer to "Interference prevention function" |

| IL- | |

| IU+ | Interference prevention terminals For details, refer to "Interference prevention function" |

| IU- | |

| O1 | Override input terminals |

| O2 | |

| X1 | Reset input terminals (When X1 and X2 are connected: manual reset, and when X1 and X3 are connected: auto reset) |

| X2 | |

| X3 | |

| T1 | Emission halt input terminals (Open: emission halt, Short-circuit: emission) |

| T2 |

Cautions For Use

- When this device is used in the "PSDI Mode", an appropriate control circuit must be configured between this device and the machinery. For details, be sure to refer to the standards or regulations applicable in each region or country.

- To use this product in the U.S.A., refer to OSHA 1910.212 and OSHA 1910.217 for installation, and in Europe, refer to EN 999 as well. Observe your national and local requirements before installing this product.

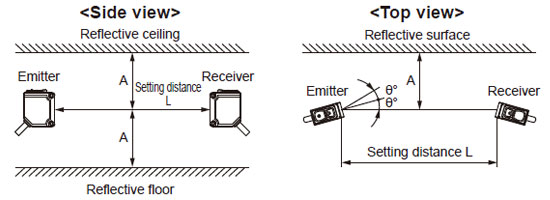

Influence of reflective surfaces

- If there exists a reflective surface in the place where this device is to be installed, make sure to install this device so that reflected light from the reflective surface does not enter into the receiver, or take countermeasures such as painting, masking, roughening, or changing the material of the reflective surface, etc. Failure to do so may cause the device not to detect, resulting in death or serious injury.

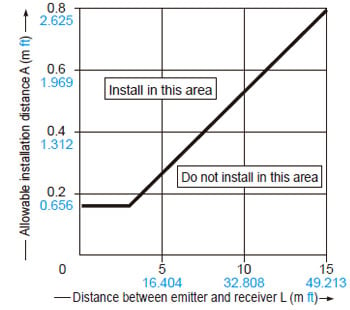

- Install this device at a distance of at least A (m) (given below) away from reflective surfaces such as metal walls, floors, ceilings, objects, covers, panels or glass surfaces.

| Distance between emitter and receiver (Setting distance L) | Allowable installation distance A |

|---|---|

| 0.1 to 3 m 0.328 to 9.843 ft | 0.16 m 0.525 ft |

| 3 to 15 m 9.843 to 49.213 ft | L/2×tan2θ=L×0.053(m) 0.174 (ft) ((θ=3°) |

Note:

The effective aperture angle for this device is ±2.5° (when L > 3 m 9.843 ft) as required by IEC 61496-2 / UL 61496-2. However, install this device away from reflective surfaces considering an effective aperture angle of ±3° to take care of beam misalignment, etc. during installation.

<Allowable installation distance between reflective surfaces and beam axis of receiver>

Mounting

- When mounting the sensor head, the tightening torque should be 0.5 N·m or less.

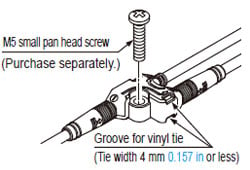

- When mounting ST4-CCJ05-WY, the tightening torque should be 0.7 N·m or less. Using a vinyl tie (width 4 mm 0.157 in or less) to fix the cable is also possible.

Wiring

- Refer to the applicable regulations for the region where this device is to be used when setting up the device. In addition, make sure that all necessary measures are taken to prevent possible dangerous operating errors resulting from earth faults.

- Make sure to carry out the wiring in the power supply off condition.

- Verify that the supply voltage variation is within the rating.

- If power is supplied from a commercial switching regulator, ensure that the frame ground (F.G.) terminal of the power supply is connected to an actual ground.

- In case noise generating equipment (switching regulator, inverter motor, etc.) is used in the vicinity of this sensor and controller, connect the frame ground (F.G.) terminal of the equipment to an actual ground.

- Do not run the wires together with high-voltage lines or power lines or put them in the same raceway. This can cause malfunction due to induction.

- It is recommended that the following single wires or twisted wires (lead wires) be used to connect to the terminal block of the controller.

・ Terminal block connector: 0.2 to 1.5 mm2 (AWG24 to AWG16)

・ Power supply connector (A1, A2) (ST4-C12EX only): 0.2 to 2.5 mm2 (AWG24 to AWG12)

Others

- This device has been developed / produced for industrial use only.

- Do not use this device with mobile equipment such as an automated guided vehicle (AGV).

- Do not use during the initial transient time (2 sec.) after the power supply is switched on.

- Avoid dust, dirt and steam.

- Take care that the sensor does not come in direct contact with water, oil, grease, or organic solvents, such as, thinner, etc.

- Take care that the sensor is not directly exposed to fluorescent lamp from a rapid-starter lamp or a high frequency lighting device, as it may affect the sensing performance.

- This product is suitable for indoor use only.

- The DC power supply unit must satisfy the conditions given below.

1) Power supply unit authorized in the region where this devices is to be used.

2) Power supply unit conforming to EMC Directive and Low voltage Directive (In case CE marking conformity is required).

3) Power supply unit conforming to EMC Regulations and Low voltage Regulations (In case UKCA marking conformity is required).

4) Power supply unit conforming to the Low-voltage Directive and with an output of 100 VA or less.

5) The frame ground (F.G.) terminal must be connected to ground when using a commercially available switching regulator.

6) Power supply unit with an output holding time of 20 ms or more.

7) If surges are likely to occur, take countermeasures such as connecting a surge absorber to the origin of the surge.

8) Power supply unit corresponding to Class 2 (In case UL / cUL conformity is required).