Safety Laser Scanner Type 3 SD3-A1 (Discontinued Products)

Download

-

Discontinued Products

-

Specifications

-

Dimensions

-

Circuit/ Wiring

-

Cautions For Use

Ⅾiscontinued

Last time buy (JST)

March 31, 2020

Please refer to the details of the discontinued products and the recommended substitutes list below.

Discontinued Products

Specifications

| Type | Safety laser scanner | ||||||

|---|---|---|---|---|---|---|---|

| Model No. | SD3-A1 | ||||||

| Applicable standards | International standards | IEC 61496-1/3 (Type 3), ISO 13849-1 (Category 3, PLd), IEC 61508-1 to 7 (SIL2), IEC 62061 (SIL2) | |||||

| Japan | JIS B 9704-1/3 (Type 3), JIS B 9705-1 (Category 3), JIS C 0508 (SIL2) | ||||||

| Europe (EU) | EN 61496-1 (Type 3), ISO 13849-1 (Category 3, PLd), EN 61508-1 to 7 (SIL2) | ||||||

| Detection zone | Min. sensing object setting | ø150 mm ø5.906 in | ø70 mm ø2.756 in | ø50 mm ø1.969 in | ø40 mm ø1.575 in | ø30mm ø1.181 in | |

| Sensing range (radius) | 0 to 4.0 m 0 to 13.123 ft | 0 to 4.0 m 0 to 13.123 ft | 0 to 2.8 m 0 to 9.186 ft | 0 to 2.2 m 0 to 7.218 ft | 0 to 1.6m 0 to 5.249 ft | ||

| Measurement error margin extended range | When dust suppression function is not selected: 83mm 3.268 in When dust suppression function is selected: 83 mm 3.268 in for less than 3.5 mm 0.138 in, and 100 mm 3.937 in for 3.5 mm 0.138 in or more (automatically calculated using the included software) | ||||||

| Sensing object reflectance | Minimum 1.8 % | ||||||

| Warning zone | Min. sensing object setting | ø150 mm ø5.906 in (fixed) | |||||

| Sensing range (radius) | 0 to 15 m 0 to 49.213 ft | ||||||

| Sensing object reflectance | Minimum 20 % | ||||||

| Measurement zone | Max. measurement range (radius) | 50 m 164.042 ft (fixed) | |||||

| Scanning angle | 190° / 180° (by setting) | ||||||

| Number of zone setting | Max. 7 + 1 (without detection zone) [Zone pairs in combination of detection zone and warning zone can be switched over by external input] | ||||||

| Min. zone setting range | 200 mm 7.874 in | ||||||

| Supply voltage (UB) | 24 V DC+20-30 % (IEC 60742) | ||||||

| Current consumption | 300 mA approx. (excluding external connection load) | ||||||

| Fuse (power supply) | 1.25 A semi-time-lag fuse | ||||||

| Control outputs (OSSD 1, OSSD 2) | PNP open-collector transistor 2 outputs • Rated operating voltage: supply voltage (UB) - 3.2 V • Max. source current: 250 mA • Residual voltage: 3.2 V or less | ||||||

| Operation mode | When no object enters into the detection zone: ON, When an object enters: OFF | ||||||

| Response time | Min. 80 ms (2 scans) to max. 640 ms (16 scans) switching method | ||||||

| Protection circuit | Incorporated | ||||||

| Warning output 1 (Alarm 1) | PNP open-collector transistor • Rated operating voltage: supply voltage (UB) - 4 V • Max. source current: 100 mA • Residual voltage: 4 V or less | ||||||

| Operation mode | Switching method of operation mode (set by below) • Not used • Main unit at normal operation: ON, Abnormal operation: OFF • When no object enters into the warning zone: ON, When an object enters: OFF • Main unit at normal operation: ON, Abnormal operation: OFF and When no object enters into the warning zone: ON, When an object enters: OFF | ||||||

| Response time | Min. 80 ms (2 scans) to max. 640 ms (16 scans) switching method | ||||||

| Warning output 2 (Alarm 2) | PNP open-collector transistor • Rated operating voltage: supply voltage (UB) - 4 V • Max. source current: 100 mA • Residual voltage: 4 V or less | ||||||

| Operation mode | Main unit at normal operation: ON, Abnormal operation: OFF | ||||||

| Laser protection class | Class 1 [IEC 60825] | ||||||

| Peak emission wavelength | 905 nm 0.036 mil | ||||||

| Degree of protection | IP65 | ||||||

| Ambient temperature | 0 to +50 ℃ +32 to +122 ℉ Storage: −20 to +60 ℃ −4 to +140 ℉ | ||||||

| Ambient humidity | Operation and storage: Max. 95 % RH (No dew condensation) | ||||||

| Vibration resistance / Shock resistance | 10 to 150 Hz frequency, 5 G max. (50 m/s2 approx.) in X, Y and Z directions for twenty times each | ||||||

| Maximum cable length | 15-pin plug: Max. 50 m 164.042 ft, 9-pin plug: Max. 10 m 32.808 ft (when using RS-232C) / Max. 50 m 164.042 ft (when using RS-422) (by using optional connection cable) (Note 1) | ||||||

| Material | Main body: Die-cast aluminum, Scanner window: Thermoplastic resin | ||||||

| Accessories | SD3-PS (exclusive 15-pin connector): 1 pc., SD3-RS232 (exclusive 9-pin connector): 1 pc., Mounting screws [M5 (length 20 mm 0.787 in) hexagon-socket-head bolt: 2 pcs., M5 (length 16 mm 0.630 in) hexagon-socket-head bolt: 2 pcs., attached to SD3-PS]:1 set, Simplified instruction manual: 1 copy, Installation CD-ROM (includes detailed instruction manual data): 1 CD | ||||||

| Weight | Net weight: 2.1 kg approx., Gross weight: 2.9 kg approx. | ||||||

Note 1: Be careful that a voltage drop may occur depending on the cable length or cable's conductor cross-section area.

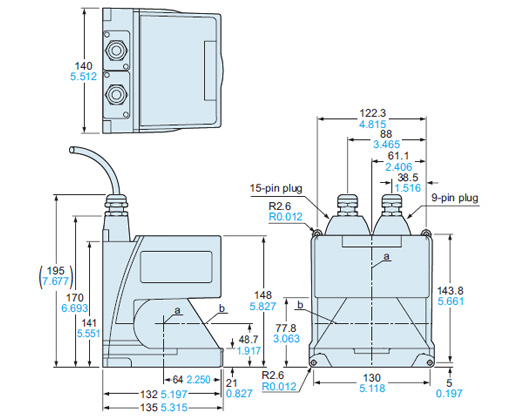

Dimensions

- Unit: mm in

SD3-A1

Safety laser scanner

a: Rotating mirror axis

b: Scan level (beam axis)

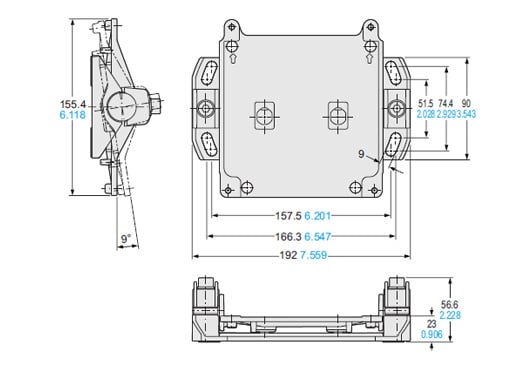

MS-SD3-1

Mounting bracket (Optional)

Material: Aluminum

Net weight: 530 g approx.

Two M8 (length 45 mm 1.772 in) hexagon-socket-head bolts, two plain washers for M8, two M5 (length 20 mm 0.787 in) hexagon-socket-head bolts, two M5 (length 16 mm 0.630 in) hexagon-socket-head bolts, and four plain washers for M5 are attached.

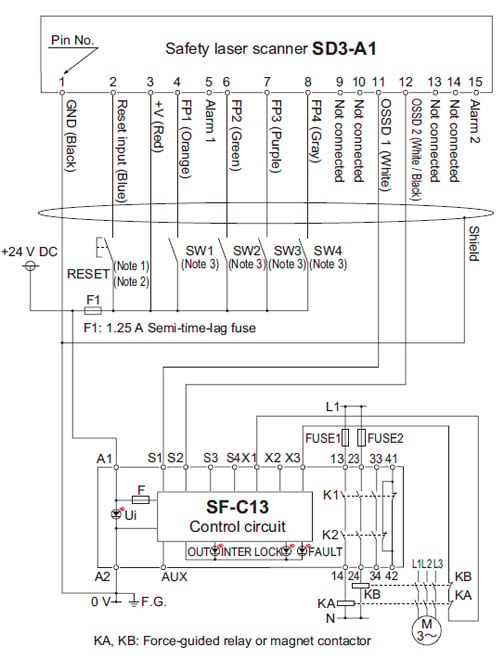

I/O Circuit and Wiring diagrams

Connection wiring example with control unit SF-C13

Notes:

1): The above diagram is when using manual reset. If automatic reset is used, a reset (RESET) button is not needed.

Settings by software are needed separately.

2): Use a momentary-type switch as the reset (RESET) button.

3): For zone-control inputs (SW1 to 4), use PLC etc. (input time should be 40 ms or less).

| Zone No. | Control inputs | |||

|---|---|---|---|---|

| FP1 | FP2 | FP3 | FP4 | |

| 1 | 1 | 0 | 0 | 0 |

| 2 | 0 | 1 | 0 | 0 |

| 3 | 0 | 0 | 1 | 0 |

| 4 | 0 | 0 | 0 | 1 |

| 5 | 1 | 1 | 1 | 0 |

| 6 | 1 | 1 | 0 | 1 |

| 7 | 1 | 0 | 1 | 1 |

| 8 | 0 | 1 | 1 | 1 |

Cautions For Use

Wiring

- Make sure that the power supply is off while wiring.

- Do not run the wires together with high-voltage lines or power lines or put them in the same raceway. This can cause malfunction due to induction.

- Faulty wiring can damage internal circuitry so check the wiring before turning the power on.

Others

- Avoid using the device in places that are humid and dusty, places where water and medicine are stored, or where there are corrosive gases in the air.

- Take care that the sensor does not come in direct contact with water, oil, grease or organic solvents, such as, thinner, etc.