Leak Detection Sensor EX-F70/EX-F60

Download

-

Basic Information

-

Order guide

-

Option

-

Specifications

-

Dimensions

-

Circuit/ Wiring

-

Cautions For Use

Partly Order Discontinued

Last time buy (JST)

September 29, 2023

Partly Order Discontinued:General purpose

------------------------------ Tab1 showing ------------------------------

Basic Information

High-speed detection even a little liquid leak

CE : EMC Directive

UKCA : EMC Regulations

UL : Recognition

Features

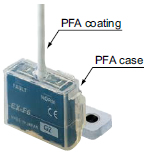

PFA enclosure gives excellent chemical resistance [EX-F60]

The sensor enclosure and the cable sheath are made from PFA which is highly resistant to chemicals. Accurate sensing is achieved even if there are leaks of chemicals such as sulfuric acid, hydrochloric acid or ammonia.

Easy installation & reset [EX-F60]

The simplified shape makes it easy to clean up after liquid leaks, simply by wiping off the liquid, and no parts need to be replaced.

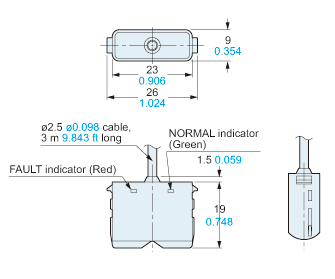

Compact, space-saving [EX-F60]

Even with its built-in amplifier, the size is compact at W26 x H19 x D9 mm W1.024 x H0.748 x D0.354 in, so that it can be used even in narrow spaces.

![Compact, space-saving [EX-F60]](https://tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/photoelectric/ex-f70/images/pic09.jpg)

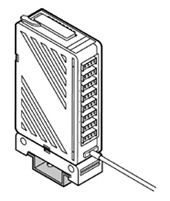

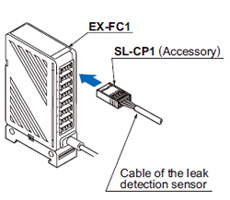

Wire-saving unit made especially for connecting leak detection sensors! [EX-FC1]

- Saves wiring! Connects up to 8 leak detection sensors

EX-FC1 is a simple wire-saving unit for exclusive use with EX-F71/72, EX-F61/F62 leak detection sensors. (It can be used with general sensors as well.)

EX-FC1 integrates the outputs from up to 8 leak detection sensors into a single OR output, so significant wiring and space savings are achieved.

* Even with only one leak detection sensor connected, an OFF signal is output if the sensor detects liquid leakage, or if the unit has been installed incorrectly.

- Slim & compact

Space savings are significant, as the ultra-thin & compact EX-FC1 has main unit body dimensions of only W20 x H80 x D52 mm W0.787 x H3.150 x D2.047 in.

- Connects easily with one-touch connector Connections are made by simply inserting the leak detection sensor cable leads into the snap male connector SL-CP1, then push until the connector snap-locks! This saves the time and the trouble of stripping the insulation from each lead before attaching to terminals.

------------------------------ Tab2 showing ------------------------------

Order guide

Leak detection sensors

| Type | Appearance | Sensing object | Cable length | Model No. | Output | |

|---|---|---|---|---|---|---|

| Chemical-resistant | PFA mounting bracket type |

| Agent, such as Water, Sulfuric acid, Hydrochloric acid, Phosphoric acid or Ammonia etc. (Note 1, 2) | 3 m 9.843 ft | EX-F61 | NPN open-collector transistor |

| EX-F61-PN | PNP open-collector transistor | |||||

| PVC mounting bracket type |

| EX-F62 | NPN open-collector transistor | |||

| EX-F62-PN | PNP open-collector transistor | |||||

Note 1:Highly viscous liquid may not be detected stably.

Note 2:The agents mentioned above are examples.

For details, please contact our office.

5 m 16.404 ft cable length type

5 m 16.404 ft cable length type (standard: 2 m 6.562 ft or 3 m 9.843 ft) is also available.

When ordering this type, suffix "-C5" to the model No.

(e.g.) 5 m 16.404 ft cable length type of EX-F61-PN is "EX-F61-PN-C5".

Simple wire-saving unit for leak detection sensor

| Appearance | Model No. | Output |

|---|---|---|

| EX-FC1 | Relay contact 1 a |

Discontinued products [Order accepted till September, 2023]

* Substitute products will not guarantee the specifications of discontinued products.

Please check the specification details from catalog before use.

------------------------------ Tab3 showing ------------------------------

Option

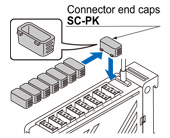

| Designation | Model No. | Description |

|---|---|---|

| Unit mounting bracket | MS-DIN-3 | Mounting bracket for EX-FC1 |

| Connector end cap | SC-PK | Connector end cap for EX-FC1 [8 pcs. per set] |

Unit mounting bracket

MS-DIN-3

Accessories

MS-EX-F7-1

(SUS mounting bracket)

MS-EX-F7-2

(PVC mounting bracket for adhesive fixing)

MS-EX-F7-3

(PVC mounting bracket for two-point fixing)

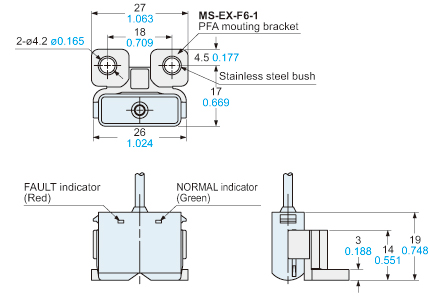

MS-EX-F6-1

(PFA mounting bracket)

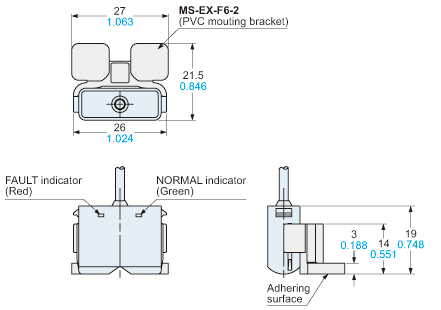

MS-EX-F6-2

(PVC mounting bracket)

SL-CP1

(Snap male connector)

[10 pcs. per set]

MS-SL-2

(Unit mounting base)

Connector end cap

------------------------------ Tab4 showing ------------------------------

Specifications

Sensors

| Type | General purpose | Chemical-resistant | |||

|---|---|---|---|---|---|

| SUS mounting bracket type | PVC mounting bracket type | PFA mounting bracket type | PVC mounting bracket type | ||

| Model No. | NPN output | EX-F71 | EX-F72 | EX-F61 | EX-F62 |

| PNP output | EX-F71-PN | EX-F72-PN | EX-F61-PN | EX-F62-PN | |

| Sensing object | Water, Fluorinert™ (Note 2, 3) | Agent, such as Water, Sulfuric acid, Hydrochloric acid, Phosphoric acid or Ammonia etc. (Note 2, 4, 6) | |||

| Supply voltage | 12 to 24 V DC ± 10 % Ripple P-P 10 % or less | ||||

| Current consumption | 10 mA or less (PNP output type: 15 mA or less) | 15 mA or less | |||

| Output | <NPN output type> NPN open-collector transistor - Maximum sink current: 50 mA - Applied voltage: 30 V DC or less (between output and 0 V) - Residual voltage: 1.0 V or less (at 50 mA sink current) 0.4 V or less (at 16 mA sink current) <PNP output type> PNP open-collector transistor - Maximum source current: 50 mA - Applied voltage: 30 V DC or less (between output and +V) - Residual voltage: 1.0 V or less (at 50 mA source current) 0.4 V or less (at 16 mA source current) | ||||

| Utilization category | DC-12 or DC-13 | ||||

| Output operation | In normal state: ON, When leak detected or the sensor is mounted improperly: OFF | ||||

| Short-circuit protection | Incorporated | ||||

| Response time | 50 ms or less | ||||

| FAULT indicator | Red LED (lights up when the leak liquid is detected, or the sensor is mounted improperly) | ||||

| NORMAL indicator | Green LED (lights up when the sensor is mounted properly) | ||||

| Pollution degree | 3 (Industrial environment) | ||||

| Protection | IP67 (IEC) | ||||

| Ambient temperature | -10 to +60 ℃ +14 to +140 ℉ (No dew condensation or icing allowed), Storage: -20 to +70 ℃ - 4 to +158 ℉ (Note 5) | ||||

| Ambient humidity | 35 to 85 % RH, Storage: 35 to 85 % RH | ||||

| Ambient illuminance | Incandescent light: 1,000 lx or less at the light-receiving face | ||||

| Emitting element | Infrared LED (non-modulated) | ||||

| Material | Enclosure: Polypropylene | Enclosure: PFA | |||

| Cable | 0.1 mm2 3-core PVC cabtyre cable, 2 m 6.562 ft long | 0.1 mm2 3-core PFA cabtyre cable, 3 m 9.843 ft long | |||

| Cable extension | Extension up to total 50 m 164.042 ft is possible with 0.3 mm2, or more, cable. | ||||

| Weight | Net weight: 25 g approx. | Net weight: 60 g approx. | |||

| Accessories | MS-EX-F7-1 (SUS mounting bracket) (Note 7): 1 pc. | MS-EX-F7-2, MS-EX-F7-3 (PVC mounting bracket) (Note 7): 1 pc. each for two-point-fixing and adhesive-fixing | MS-EX-F6-1 (PFA mounting bracket): 1 pc. | MS-EX-F6-2 (PVC mounting bracket): 1 pc. | |

Note 1:Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +20 ℃ +68 ℉.

Note 2:Highly viscous liquid may not be detected stably.

Note 3:Fluorinert is the world wide trademark of 3M.

Note 4:The agents mentioned above are examples. For details, please contact our office.

Note 5:Liquid being detected should also be kept within the rated ambient temperature range.

Note 6:PVC mounting bracket may not be used depending on type or viscosity etc. of the agent. For details, please contact our office.

Note 7:The mounting bracket for EX-F71(-PN) is not interchangeable with that of EX-F72(-PN) due to the different sensitivity settings of each sensor.

Simple wire-saving unit

| Designation | Simple wire-saving unit for leak detection sensor | |

|---|---|---|

| Model No. | EX-FC1 | |

| Applicable connector | SL-CP1 | |

| Supply voltage | 12 to 24 V DC ± 10 % Ripple P-P 10 % or less | |

| Current consumption | 50 mA or less (for the unit itself), 135 mA or less (including the sensor input current when all outputs of sensors are ON) | |

| Output | Relay contact 1a - Switching capacity: 30 V 1 A DC (resistive load) - Min. applied load: 10 mV 10 μA DC - Electrical lifetime: 100,000 switching operations or more (rated load, switching frequency 20 operations/min.) - Mechanical lifetime: 50 million switching operations or more (switching frequency 180 operations/min.) | |

| Utilization category | DC-12 or DC-13 | |

| Output operation | The output relay is ON when the input signal from the sensor is ON (Note 2) | |

| Response time | 5 ms or less (excluding the response time of the sensor) | |

| Input No. | 8 Nos. | |

| Indicators | Normal | Green LED x 8 (light up when the sensor is connected to each channel and the connection setting switch is set to ON) |

| Error | Red LED x 8 (light up when the leak liquid is detected by a sensor connected to each channel or a sensor is mounted improperly) | |

| Output | Orange LED (lights up when the output relay is ON (normal)) | |

| Pollution degree | 3 (Industrial environment) | |

| Ambient temperature | -10 to +60 ℃ +14 to +140 ℉ (No dew condensation or icing allowed), Storage: -20 to +70 ℃ -4 to +158 ℉ | |

| Ambient humidity | 35 to 85 % RH, Storage: 35 to 85 % RH | |

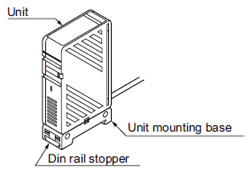

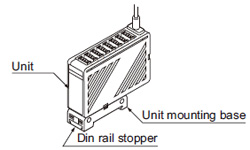

| Material | Enclosure: ABS, Unit mounting base: POM, Terminal part: PBT | |

| Cable | 0.2 mm2 4-core cabtyre cable, 2 m 6.562 ft long | |

| Cable extension | Extension up to total less than 10 m 32.808 ft is possible, with 0.3 mm2, or more, cable. | |

| Weight | Net weight: 85 g approx. | |

| Accessories | SL-CP1 (Snap male connector): 8 pcs., MS-SL-2 (Unit mounting base): 1 pc. | |

Note 1:Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +20 ℃ +68 ℉.

Note 2:Even with only one leak detection sensor connected, an OFF signal is output if the sensor detects liquid leakage, or if the unit has been installed incorrectly.

------------------------------ Tab5 showing ------------------------------

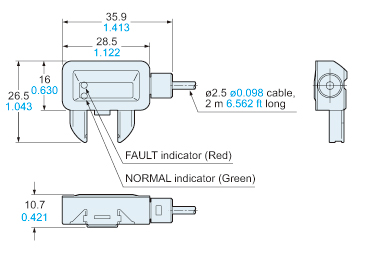

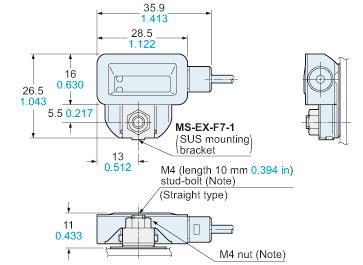

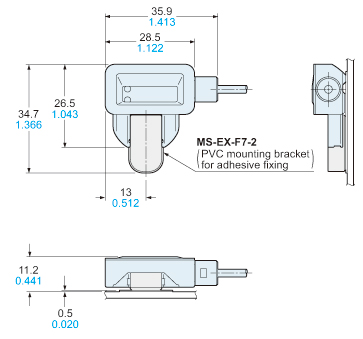

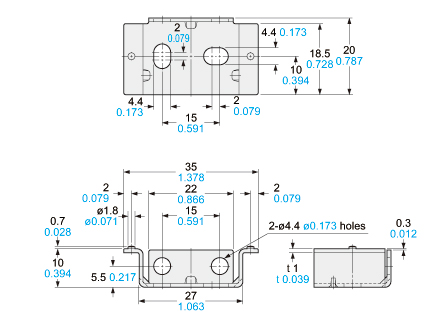

Dimensions

- Unit: mm in

EX-F71(-PN) EX-F72(-PN)

Sensor

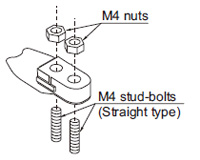

Assembly dimensions with mounting bracket for EX-F71(-PN)

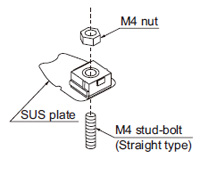

Note:A M4 stud-bolt has been welded to this unit.M4 nut is not supplied with the sensor.Please arrange it separately.

Assembly dimensions with mounting bracket for EX-F72(-PN)

MS-EX-F7-3 / For two-point-fixing

Note:M4 stud-bolts have been welded to this unit.M4 nuts are not supplied with the sensor.Please arrange it separately.

MS-EX-F7-2 / For adhesive fixing

EX-F61(-PN) EX-F62(-PN)

Sensor

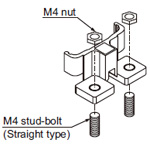

Assembly dimensions with mounting bracket for EX-F61(-PN)

Assembly dimensions with mounting bracket for EX-F62(-PN)

EX-FC1

Simple wire-saving unit for leak detection sensor

MS-DIN-3

Amplifier mounting bracket (Optional)

Material:Cold rolled carbon steel (SPCC)(Uni-chorome plated)

------------------------------ Tab6 showing ------------------------------

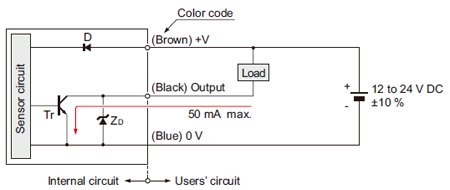

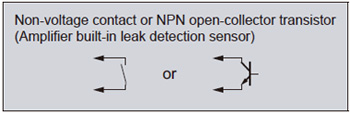

I/O Circuit and Wiring diagrams

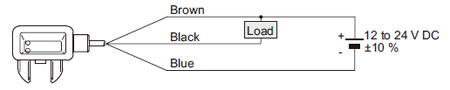

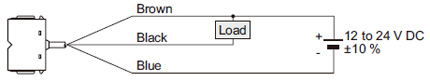

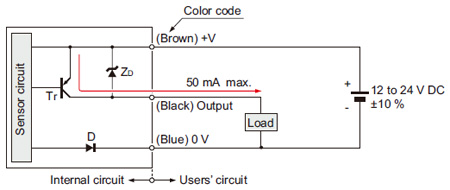

EX-F7□ EX-F6□

NPN output type

I/O circuit diagram

Symbols・・・

D: Reverse supply polarity protection diode

ZD: Surge absorption zener diode

Tr : NPN output transistor

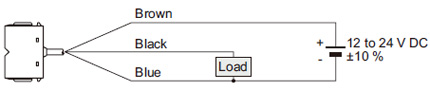

Wiring diagram

EX-F7□

EX-F6□

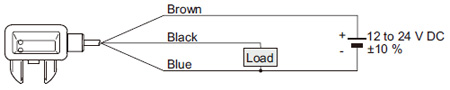

EX-F7□-PN EX-F6□-PN

PNP output type

I/O circuit diagram

Symbols・・・

D: Reverse supply polarity protection diode

ZD: Surge absorption zener diode

Tr : NPN output transistor

Wiring diagram

EX-F7□-PN

EX-F6□-PN

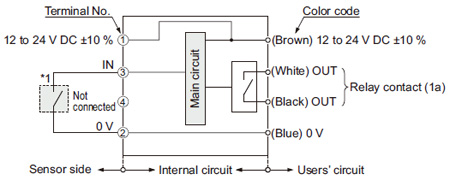

EX-FC1

Simple wire-saving unit for leak detection sensor

I/O circuit diagram (for one channel)

Note:The output does not incorporate a short-circuit protection circuit.Do not connect it directly to a power supply or a capacitive load.

*1

------------------------------ Tab7 showing ------------------------------

Cautions For Use

- Never use this product as a sensing device for personnel protection.

- In case of using sensing devices for personnel protection, use products which meet laws and standards, such as OSHA, ANSI or IEC etc., for personnel protection applicable in each region or country.

EX-F71(-PN) EX-F72(-PN)

Mounting

EX-F71(-PN)

- Insert the M4 stud-bolt (length 10 mm 0.394 in or more) welded on the user’s facilities into the mounting hole of the SUS mounting bracket and screw with an M4 nut (please arrange separately). The tightening torque should be 0.98 N·m or less.

EX-F72(-PN)

- Insert M4 stud-bolts (length 10 mm 0.394 in or more) welded on the user’s facilities into the mounting holes of the two-point-fixing mounting bracket and screw with M4 nuts (please arrange separately). The tightening torque should be 0.49 N·m or less.

- Use adhesive to stick fast the mounting bracket on the mounting surface. Please note that if the adhesive sticks out from the bottom surface of the mounting bracket or is 0.5 mm 0.020 in, or more thick, the sensor body cannot be fitted to the mounting bracket.

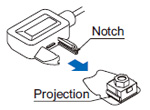

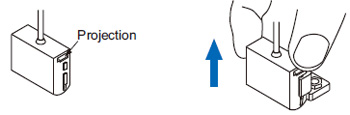

- Match the notch in the sensor body with the projection of the exclusive mounting bracket and slide till a click is felt.

- When mounting, make sure to use the brackets included with the unit in order to eliminate human error (such as forgetting to install). If the included brackets are not used, stable sensing is rendered impossible. Also, because sensitivity settings differ between the EX-F71(-PN) and the EX-F72(-PN), their brackets cannot be interchanged.

EX-F61(-PN) EX-F62(-PN)

Mounting

EX-F61(-PN)

- Insert the M4 stud-bolt (length 10 mm 0.394 in or more) welded on the user’s facilities into the mounting hole of the PFA mounting bracket and screw with an M4 nut (please arrange separately). The tightening torque should be 0.98 N·m or less.

EX-F62(-PN)

- Please note that if the excess adhesive from the bottom surface of the exclusive mounting bracket is remained, the sensing capability may be affected. Use adhesive for vinyl chloride (PVC).

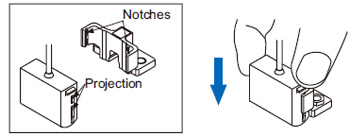

How to fit the sensor body to the exclusive mounting bracket

- Align the projections in the sensor body with the notches of the exclusive mounting bracket and slide till a click is felt.

- Pinch the projections of the sensor body and pull the body upwards. Never pull the cable, since it may cause a cable break.

EX-FC1

Mounting

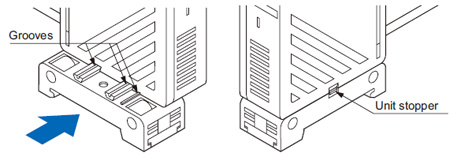

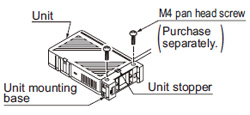

- When mounting the unit, be sure to use the unit mounting base (MS-SL-2) (accessory).

- When installing the unit mounting base to the unit, insert the base aligned with the grooves of the unit and move until the unit stopper is locked.

- Two installation positions are available for the unit mounting base so that the unit direction can be changed. Install the base at one of them.

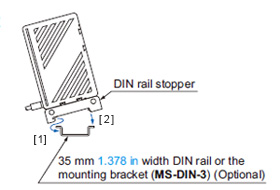

<In case of using a DIN rail or the mounting bracket (MS-DIN-3) (optional)>

[1]Fit the rear part of the unit mounting base on a 35 mm 1.378 in width DIN rail or the mounting bracket (MS-DIN-3) (optional).

[2]Press down the front part of the unit mounting base on the 35 mm 1.378 in width DIN rail or the mounting bracket (MS-DIN-3) (optional) and fit the front part of the base.

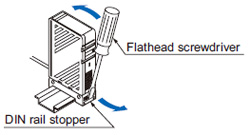

*For removal, insert a flathead screwdriver into the DIN rail stopper and pull towards yourself.

- Mount using M4 pan head screws with a tightening torque of 0.8 N·m or less. However, in case of side mounting, make sure to mount the unit such that the unit stopper faces front.

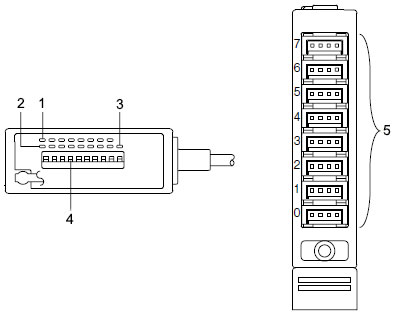

Part description

| Designation | Function | |

|---|---|---|

| 1 | Normal indicator (Green LED x 8) | Lights up when sensors are connected to each channel and the connection setting switch is set to ON. |

| 2 | Error indicator (Red LED x 8) | Lights up when leak is detected by any sensor connected or any sensor is mounted improperly. |

| 3 | Output indicator (Orange LED) | Lights up when the output relay is ON (Normal). |

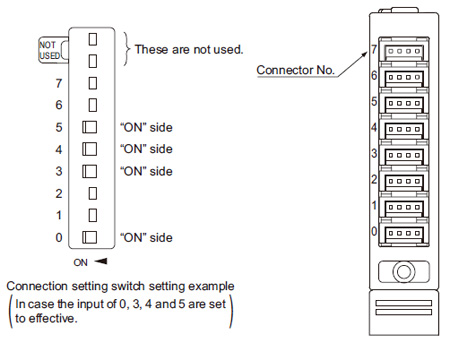

| 4 | Connection setting switch | Set the switch to ON when the leak detection sensor is connected, set to OFF when the leak detection sensor is not connected. |

| 5 | Connector | Connect the leak detection sensors. |

Connection

• Make sure to connect or disconnect the snap male connector (SL-CP1) in the power supply off condition.

• Take care that wrong wiring will damage the product.

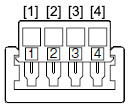

• The terminal No. 4 of the snap male connector (SL-CP1) is not used. Take care not to connect to the terminal No. 4 by mistake. Further, if there are unused wires, please insulate them.

| Content | |

| [1] | +V |

| [2] | 0V |

| [3] | IN |

| [4] | No connected |

• For details of the hook-up method of the snap male connector (SL-CP1), refer to the Instruction Manual enclosed with SL-CP1.

Connection method

Disconnection method

Note:

Do not pull out by holding the cable, as this can result in cable disconnection.

- By holding the SL-CP1 with the cable connected, insert it into the connector of the EX-FC1 reliably till it stops.

- By holding SL-CP1, pull it from the EX-FC1 horizontally.

EX-FC1

Connection setting switch

• The connection setting should be carried out in the power supply off condition after removing any electrostatic charge which may be present on your body.

Operation matrix for each indicator

| Operation | Connection state of the leak detection sensor | State of the connection setting switch | Leak detected condition | Normal indicator (Green) | Error indicator (Red) | Output indicator (Orange) |

|---|---|---|---|---|---|---|

| Normal | Connected | ON | Not leaked | Lights up | Turns off | Lights up |

| Leaked | Turns off | Lights up | Turns off | |||

| Unconnected | OFF | - | Turns off | Turns off | Lights up | |

| Error | Connected | OFF | Not leaked | Lights up | Lights up | Turns off |

| Unconnected | ON | - | Turns off | Lights up | Turns off |

- For the channel that the unit sensor is connected to and the connection setting switch is set to “ON” side, the error indicator (red) lights up for a moment when the power is turned on. This is not a malfunction for the unit because it is caused by characteristic of the sensor.

- Make sure to set the connection setting switch with the connector No. to which the leak detection sensor is connected, to “ON” side.

- In case both the normal indicator (green) and the error indicator (red) light up, the connection setting switch with the connector No. to which the leak detection sensor is connected, is not set to “ON” side. Set the connection setting switch with the connector No. to which the leak detection sensor is connected, to “ON” side.

- In case the error indicator (red) lights up, the leak detection sensor detects leak or the connection setting switch is set to “ON” side without connecting the leak detection sensor. If the connection setting switch is set to “ON” side without connecting the leak detection sensor, set the connection setting switch to “OFF” side.

- If the leak detection sensor detects leak or the connection setting switch is set to “OFF” side in the state that the leak detection sensor is improperly mounted to the mounting bracket, the sensor judges as the output is ON. Be careful when setting.

All models

Wiring

- Make sure that the power supply is off while wiring.

- Verify that the supply voltage variation is within the rating. Take care that if a voltage exceeding the rated range or an AC power supply is directly applied, the sensor may get damaged or burnt.

- If power is supplied from a commercial switching regulator, ensure that the frame ground (F.G.) terminal of the power supply is connected to an actual ground.

- In case noise generating equipment (switching regulator, inverter motor,etc.) is used in the vicinity of this product, connect the frame ground (F.G.) terminal of the equipment to an actual ground.

- Do not run the wires together with high-voltage lines or power lines or put them in the same raceway. This can cause malfunction due to induction.

- Make sure to use an isolation transformer for the DC power supply. If an auto-transformer (single winding transformer) is used, this product or the power supply may get damaged.

- In case a surge is generated in the used power supply, connect a surge absorber to the supply and absorb the surge.

- Cable extension is possible up to total 50 m 164.05 ft with 0.3 mm2, or more, cable (less than 10 m 32.81 ft for EX-FC1). However, in order to reduce noise, make the wiring as short as possible.

- Make sure that stress by forcible bend or pulling is not applied directly to the sensor cable joint.

- EX-FC1 output dose not incorporate a short-circuit protection circuit. Do not connect it directly to a power supply or a capacitive load.

Others

• Avoid using the product in an explosive atmosphere because this product does not have an explosive-proof protective construction.

• When liquid remains on the sensing surface after leak detection, wipe all liquid from the sensing surface. To avoid scratching the sensing surface and the enclosed mounting bracket, use a soft cloth.

- In case air bubbles are drawn into the sensing part, take care that it may take some time for sensing to stabilize, or sensing may even become unstable. Check the usage conditions thoroughly before use.

- Do not use during the initial transient time (leak detection sensor: 50 ms approx., EX-FC1: 0.5 sec. approx.) after the power supply is switched on.

- Since this sensor employs non-modulated infrared LED, take sufficient care against extraneous light. Do not expose the sensing part directly to the extraneous light.

- Avoid dust, dirt, and steam. Further, do not use this product in an environment containing organic solvents.

- Take care that EX-7□(-PN) and EX-FC1 does not come in contact with oil, grease or organic solvents, such as, thinner, etc.

- In case this sensor is used where electrostatic charge is present, use a metal leak pan, which should be connected to an actual ground.

- These sensors are only for indoor use.