FAYb Laser Marker LP-RV

Download

-

Basic Information

-

Applications

-

Option

-

Specifications

-

Dimensions

------------------------------ Tab1 showing ------------------------------

Basic Information

Short Pulse Fiber Laser

GB : Conforming to GB 7247.1

UKCA : From the production on October, 2022.

Features

In 1999, we introduced the FAYb laser marker LP-F series, the world's first laser markers equipped with a fiber oscillator. Since then, we have launched various product lineups as a leading manufacturer of fiber laser markers for approximately 20 years.

The fiber oscillation system is recognized as an ecological system because its consumption power is low and the laser diode service life is long compared with YAG or YVO4. However, there was a problem that it's difficult to generate short pulse laser.

Through adopting a new three-unit configuration, the LP-RV series with fiber oscillation system has realized a short pulse with the pulse duration of 1 ns.

This will contribute to providing overwhelming improvement on expressive power and application needs.

Pulse oscillation fiber laser marker (FAYb laser)

What is FAYb laser?

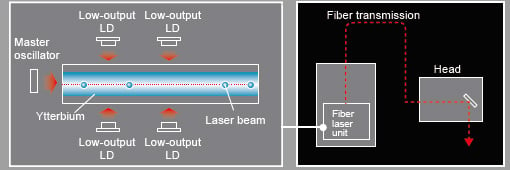

In a revolutionary method, the FAYb laser amplifies a weak laser beam from a master oscillator as it passes through a fiber treated with the element ytterbium to emit a strong laser beam.

Long life and high reliability

The LD contains reliable and durable InGaAs (gallium indium arsenide). Since the LD lights only during marking, the heat load remains minimal and the product provides a long life.

High efficiency and energy saving

Because laser amplification takes place inside the fiber containing ytterbium, high beam-to-beam conversion efficiency of approximately 50 % is achieved.

Compact head

The amplification section is contained inside the oscillator unlike solid lasers such as YVO4, so the head is compact and contributes to the reduction of equipment size.

Short Pulse Laser

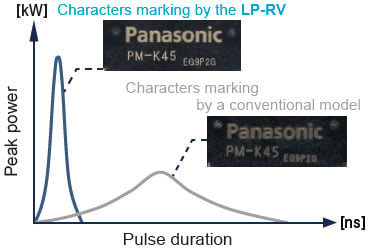

Through adopting our new technology, the new series with fiber system has achieved to generate a short pulse with the pulse duration of 1 ns.

The expressive power has been overwhelmingly improved.

Small thermal effect

As the thermal effect caused by the short pulse laser on the workpiece is small, burning, discoloration, or deformation due to heat is minimized. Therefore, the short pulse laser can be used as an optimal laser marker for devices where the thermal effect need to be suppressed such as ICs or thin metals or for high contrast marking on resin surfaces.

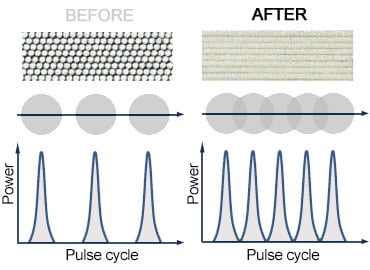

High repetition pulse oscillation

As the LP-RV can generate a short pulse laser beam in high repetition pulse oscillation, even if the laser beam is scanned at a higher speed, marking or processing is possible without spaces between laser-irradiated dots as shown on the right figure. This contributes to shortening the laser marking or processing takt time and to improving the quality.

Marking extra small characters

As the short pulse laser can prevent heat from spreading when laser is irradiated on a workpiece, it allows marking characters in much finer line segment.

It is possible to mark characters as small as 0.15 mm × 0.15 mm 0.006 in × 0.006 in. Marked characters are highly visible, not illegible at all.

Easy to install

Three-unit configuration

The laser marker features a three-unit configuration that allows each one of the three individual units to be separately removed and replaced depending on the problem in case any problem occurs. It contributes to shortening the down time.

* Before removing the unit, please contact your sales representative.

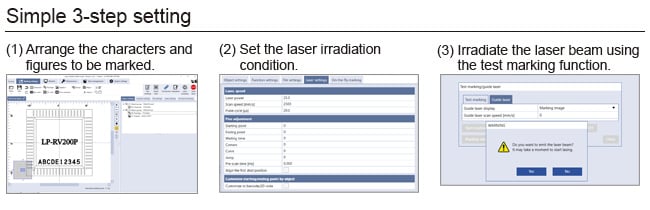

Easy setting

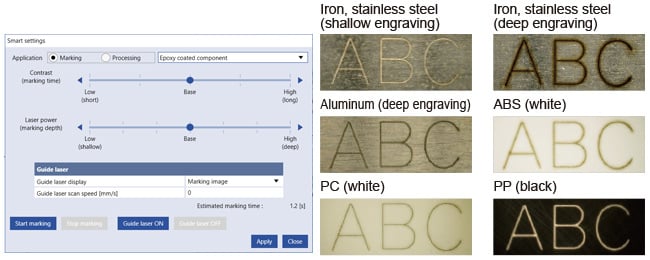

Laser Marker NAVI smart

Using the software, characters, logo marks, and 2D code can be set and arranged on a PC or tablet. The screen layout can be customized to suit each work environment. The screen can be switched according to the purpose of use, such as for parameter setting or for workers.

【Smart condition setting function】

The one-touch function is packed with our extensive know-how of laser marking parameters such as laser power, scan speed and pulse oscillation frequency. The user can select a desired marking result from 14 types of material and image.

Open network connection (optional)

If you connect EtherNet/IP or PROFINET to the laser marker using the laser marker communication unit*, marking contents or laser parameters can be set via the open network.

* Optional

LP-ANW10:EtherNet/IP

LP-ANW11:PROFINET

PROFINET is a registered trademark of PROFIBUS and PROFINET International.

EtherNet/IP is a registered trademark of ODVA (Open DeviceNet Vendor Association Inc.).

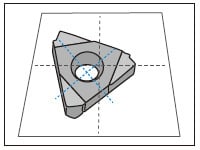

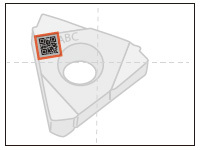

Direct linkage with machine vision system

Automatic marking position correction and scan check

The LP-RV series can be connected directly to the PV230 series machine vision system.

This enables the execution of a series of operations, such as detection of the position of approximately placed workpiece, correction of the laser irradiation position, laser marking, and cross-checking of scanned information of marked QR code, etc., without using a PLC.

[PV230]

End of order : End of March 2025

The PV230 scans and detects the position of the workpiece placed in the equipment.

Laser marking

The angle is corrected based on the scanned position information before the LP-RV irradiates laser beam.

Cross-check of scanned code information

Whether the marked 2D code can be scanned properly is checked, and the scanned information is crosschecked with the marking data.

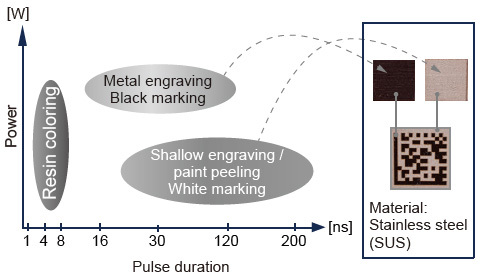

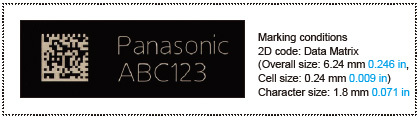

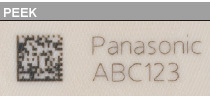

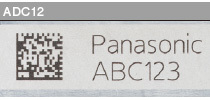

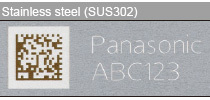

Rich marking expressions

LP-RV series short pulse laser not only allows color marking on resin materials, but also provides higher marking quality for various materials and faster marking speed. The following section shows parameters for marking condition as reference.

* Each parameter value is given for reference. Marking state varies depending on the surface condition, etc. of the material used.

* Note that corrections may have been applied to some of the laser settings given below with respect to marking conditions for surface preparation, characters, and 2D codes. For further details about the parameter values, please contact us.

Power: 35 %, Scan speed: 1,000 mm/s 39.370 in/s

Pulse duration: 4 ns, Pulse cycle: 9 μs

Marking takt: 0.9 sec.

Power: 50 %, Scan speed: 1,000 mm/s 39.370 in/s

Pulse duration: 4 ns, Pulse cycle: 8 μs

Marking takt: 0.7 sec.

Power: 40 %, Scan speed: 1,000 mm/s 39.370 in/s

Pulse duration: 4 ns, Pulse cycle: 17 μs

Marking takt: 2.1 sec.

Power: 40 %, Scan speed: 1,000 mm/s 39.370 in/s

Pulse duration: 200 ns, Pulse cycle: 40 μs

Marking takt: 0.6 sec.

Power: 70 %, Scan speed: 1,000 mm/s 39.370 in/s

Pulse duration: 8 ns, Pulse cycle: 24 μs

Marking takt: 0.6 sec.

Power: 70 %, Scan speed: 1,000 mm/s 39.370 in/s

Pulse duration: 4 ns, Pulse cycle: 12 μs

Marking takt: 0.6 sec.

Power: 80 %, Scan speed: 1,000 mm/s 39.370 in/s

Pulse duration: 16 ns, Pulse cycle: 6.2 μs

Marking takt: 0.9 sec.

Power: 80 %, Scan speed: 1,500 mm/s 59.055 in/s

Pulse duration: 200 ns, Pulse cycle: 90 μs

Marking takt: 0.6 sec.

Power: 35 %, Scan speed: 1,000 mm/s 39.370 in/s

Pulse duration: 4 ns, Pulse cycle: 9 μs

Marking takt: 0.9 sec.

Power: 80 %, Scan speed: 1,000 mm/s 39.370 in/s

Pulse duration: 16 ns, Pulse cycle: 6.2 μs

Marking takt: 4.6 sec.

Power: 80 %, Scan speed: 1,000 mm/s 39.370 in/s

Pulse duration: 8 ns, Pulse cycle: 6.2 μs

Marking takt: 4.6 sec.

Power: 80 %, Scan speed: 60 mm/s 2.362 in/s

Pulse duration: 16 ns, Pulse cycle: 0.7 μs

Marking takt: 18.4 sec.

Power: 40 %, Scan speed: 1,000 mm/s 39.370 in/s

Pulse duration: 120 ns, Pulse cycle: 20 μs

Marking takt: 0.9 sec.

Power: 60 %, Scan speed: 100 mm/s 3.937 in/s

Pulse duration: 16 ns, Pulse cycle: 6.2 μs

Marking takt: 0.7 sec.

Power: 25 %, Scan speed: 1,000 mm/s 39.370 in/s

Pulse duration: 120 ns, Pulse cycle: 30 μs

Marking takt: 0.6 sec.

Power: 35 %, Scan speed: 1,000 mm/s 39.370 in/s

Pulse duration: 4 ns, Pulse cycle: 9 μs

Marking takt: 0.9 sec.

------------------------------ Tab2 showing ------------------------------

Applications

Small electronic part

Nameplate

Resin mold

Gold plating peeling

IC package

Illuminated switch

Metal part

Cleaning process

------------------------------ Tab3 showing ------------------------------

------------------------------ Tab4 showing ------------------------------

Specifications

| Item | LP-RV200P | |

|---|---|---|

| Marking laser | Laser type | Yb fiber laser; λ= 1,064 nm 0.0419 mil Class4 laser |

| Average oscillator output | 20 W | |

| Average output at processing point (Note 1) | 17 W (±5 %) | |

| Laser oscillation system | Pulse oscillation | |

| Pulse duration | 1 ns, 4 ns, 8 ns, 16 ns, 30 ns, 120 ns, 200 ns (switchable in seven steps) | |

| Pulse cycle (Note 2) | 0.5 μs to 500 μs | |

| Guide laser / pointer | Red semiconductor laser; λ= 655 nm 0.026 mil, Class 2 laser, Maximum output; 1 mW or less | |

| Scanning method | Galvano scanning method | |

| Beam shielding device | Shutter (mounted inside the head) | |

| Marking field (X, Y) (Note3) | 90 mm × 90 mm 3.543 in × 3.543 in | |

| Work distance (Note 3) | 190 mm 7.480 in | |

| Marking workpiece status | Stationary object, moving object | |

| Scan speed (Note 4, 5) | Maximum 12,000 mm/sec. 472.441 in/sec. | |

| Moving object line speed (Note 4) | Maximum 240 m/min 787.402 ft/min | |

| Number of registered files | 10,000 files | |

| Number of marking data (number of registered objects) | 2,000 items/file | |

| Marking object types | Character types | Capital and small letter of alphabet, numeric, symbol, user defined characters (up to 50 characters can be set) Japanese characters: Katakana, Hiragana, Kanji (JIS level-1 and level-2) Simplified Chinese characters: GB 2312 level-1 and level-2 |

| Barcodes | CODE39, CODE93, CODE128 (GS1-128) , ITF, NW-7, EAN/UPC/JAN, GS1 DataBar Limited, GS1 DataBar Stacked, GS1 DataBar Limited CC-A, GS1 DataBar Stacked CC-A | |

| 2D codes | QR Code, Micro QR Code, iQR Code, Data Matrix, GS1 Data Matrix, PDF417 | |

| Graphic data (Note 6) | VEC, DXF, HPGL, BMP, JPEG, AI, EPS | |

| TrueType | TrueType Font on a PC where the Laser Marker NAVI smart is installed (Note 7) | |

| Data for processing | Point radiation | |

| Character height and width (Note 4) | 0.1 mm to 90 mm 0.004 in to 3.543 in (Set in increments of 0.001 mm 0.0394 mil) | |

| I/O port | I/O terminal block (40 pins), I/O connector (40 pins) | |

| Communication interface | EIA-RS-232C, Ethernet, EtherNet/IP (Note 8), PROFINET (Note 8) | |

| Dedicated software | Laser Marker NAVI smart, logo data editing software, ExportVec, font maker software | |

| OS supported by the dedicated software (Note 9) | Windows® 11 Pro (64-bit), Windows® 10 Pro (32-bit, 64-bit) | |

| Laser Marker NAVI smart connection method | USB, Ethernet | |

| Laser Marker NAVI smart display language | Japanese, English, Simplified Chinese character, Traditional Chinese character, German, Korean | |

| System startup time | 10 sec. approx. | |

| Laser excitation time | 1 sec. approx. | |

| Power supply (Note 10) | 180 - 264 V AC (including power voltage fluctuation of ±10 %), 50/60 Hz | |

| Consumption power (consumption current) (Note 11) | 310 VA or less (2.1 A or less) | |

| Cooling method | Head: Naturally air cooling, Controller / oscillator unit: Forced air cooling | |

| Ambient temperature (Note 12, 13) | 0 to +40 ℃ +32 to +104 ℉ | |

| Ambient temperature for storage (Note 13) | -10 to +60 ℃ +14 to +140 ℉ | |

| Ambient humidity (Note 13) | 35 to 85 % RH | |

| Head protective structure (Note 14) | IP64 | |

| Applicable standards and certificates | FDA Regulations, Chinese Standard GB 7247.1, CE Marking [Machinery Directive (Declaration of Incorporation), EMC Directive, RoHS Directive], UKCA Marking [Supply of Machinery (Safety) Regulations (Declaration of Incorporation), EMC Regulations, RoHS Regulations] | |

| Fiber cable length | 2.0 m ±0.2 m 6.562 ft ±0.656 ft, Minimum bending radius 80 mm 3.15 in | |

| Net weight | Head | 8.0 kg approx. |

| Oscillator unit | 13 kg approx. | |

| Controller | 28 kg approx. | |

Notes:

1) Indicates the output for the following settings: laser power: 100, pulse duration: 4 ns, and pulse cycle: 1.6 μs. (Factory default)

2) The pulse cycle setting range varies depending on the pulse duration.

3) There is an individual difference of approximately ±0.5 mm 0.020 in for every product.

4) The indicated values show the allowable setting range. The setting values that can maintain the marking / processing quality vary depending on the marking condition and target material.

5) Depending on the setting data, the scan speed may be subject to upper-limit restriction in some cases.

6) VEC is a figure file format designed exclusively for laser markers. If figure files in the AI or EPS format are used, they must be converted to VEC-format files in advance using the ExportVEC software provided with the product.

7) Depending on the character type, it may not be possible to use the laser marker. Letters written from right to left (Arabic letters, Hebrew letters, etc.) and letters that use ligature (Indian letters, etc.) cannot be marked using the laser marker.

8) For communication, prepare optional items separately. LP-ANW10: EtherNet/IP, LP-ANW11: PROFINET

9) The OS versions for which Microsoft terminated its support are excluded from supported OS.

10) Frequency is selected and set automatically.

11) The rush current (typical value) at startup is as follows: 220 V AC (current flowing time of 10 ms or less): 60 A

12) Laser power setting of 46 or higher: 0 to +36 ℃ +32 to +97 ℉, Laser power setting of 1 to 45: 0 to +40℃ +32 to +104 ℉

13) Common to the controller, head, and oscillator unit. There must be no dew condensation or icing. If there is a temperature difference between the storage place and the operating place, gradually adapt the devices to the ambient temperature to prevent condensation.

14) The oscillator and controller are not designed as protective structures. The protective structure of the head exhibits its performance only when the fiber unit, laser beam emission port protection glass, various cables, and cable connector covers are all properly mounted.

PROFINET is a registered trademark of PROFIBUS and PROFINET International.

EtherNet/IP is a registered trademark of ODVA (Open DeviceNet Vendor Association Inc.).

Windows is a registered trademark or trademark of Microsoft Corporation in the United States and other countries.

Precautions for Proper Use

Laser safety

- This product is classified as a Class 4 Laser Product in laser safety related standards and regulations (IEC, EN, JIS, FDA, GB). Never look at or touch the direct laser beam and its reflection.

- The labels shown on the right are attached to the product.

Handle the product according to the instruction given on the warning labels. (Warning labels are not shown in the product photographs in this catalog.) - The laser used by this product generates infrared light that is invisible to the human eye. Use particular caution when the laser is operating.

- Warning / instruction labels

Recommended use of a dust collector

- Depending on the object being marked, harmful gasses or smoke that have a detrimental effect on the human body or the laser marker may be generating during marking. If your application falls under this description, use a dust collector. For more information, contact your sales representative.

------------------------------ Tab5 showing ------------------------------

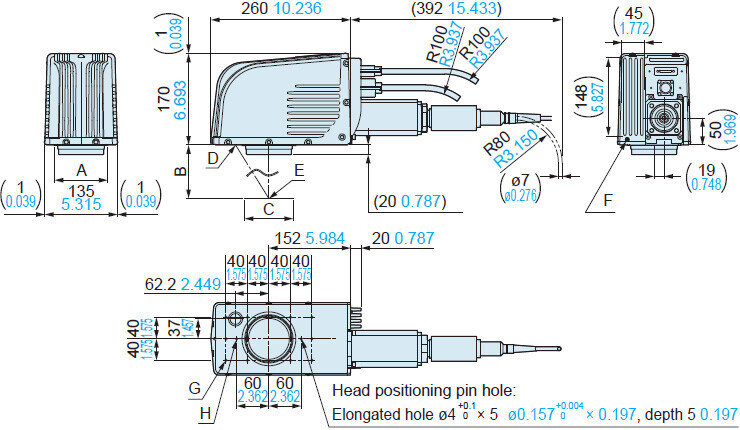

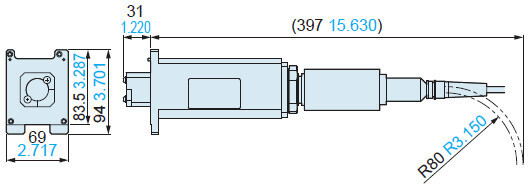

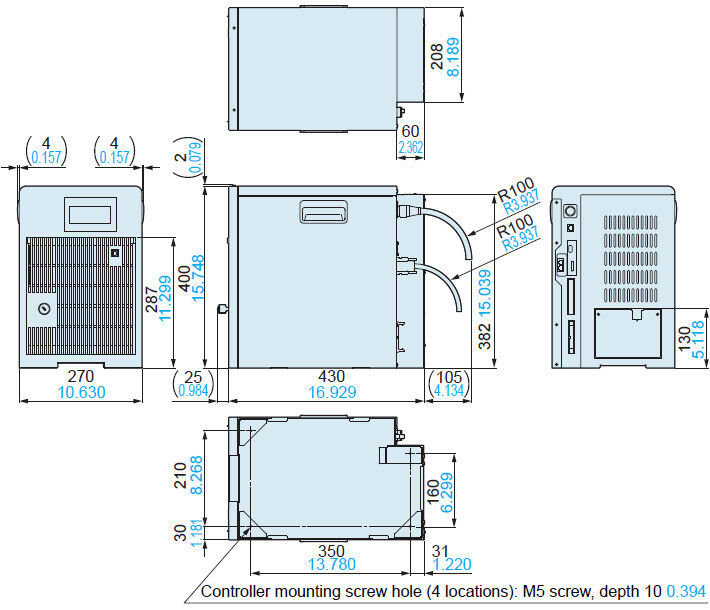

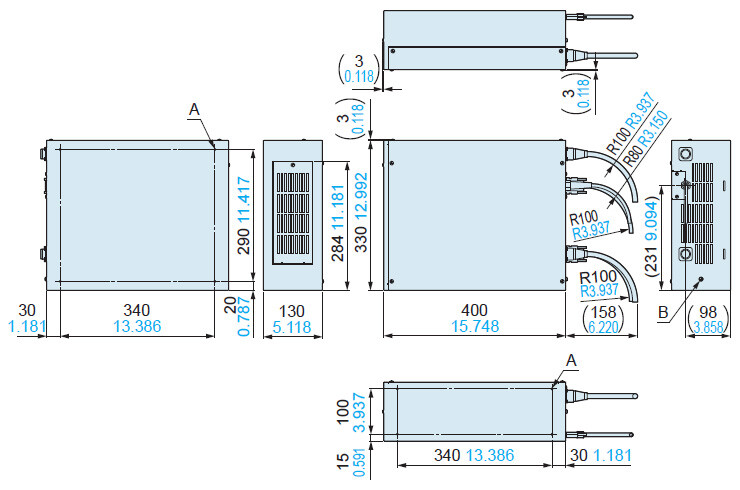

Dimensions

- Unit: mm in

LP-RV200P

Head

A: Laser beam emission port diameter (protruded section): ø100 mm ø3.937 in

B: Work distance: 190 mm 7.480 in

C: Marking field (X, Y): 90 × 90 mm 3.543 × 3.543 in

D: Laser pointer beam emission port diameter: ø26 mm ø1.024 in (lens section: ø20 mm ø0.787 in)

E: Center of marking area

F: Frame grounding screw: M4 screw, depth 5 0.197

G: Head mounting screw hole (10 locations*): M6 screw, depth 6 0.236

*Use six or more screws to mount the head

H: Head positioning pin hole:ø4+0.10ø0.157+0.0040 depth 5 0.197

Fiber unit

With fiber unit removed

Controller

* AC power cable is not attached to the laser marker body. (Sold separately)

Oscillator

A:Oscillator securing screw holes (4 holes each in the bottom and on the left side (facing the front)): M5 screws, depth 6 0.236

B:Frame grounding screw: M4 screw, depth 5 0.197