FAYb Laser Marker LP-RF

Download

-

Basic Information

-

Applications

-

Option

-

Specifications

-

Dimensions

------------------------------ Tab1 showing ------------------------------

Basic Information

Simple & High Quality

CE : From the production on September, 2019.

GB : Conforming to 7247.1

UKCA : From the production on October, 2022.

Features

Pulse oscillation fiber laser marker (FAYb laser)

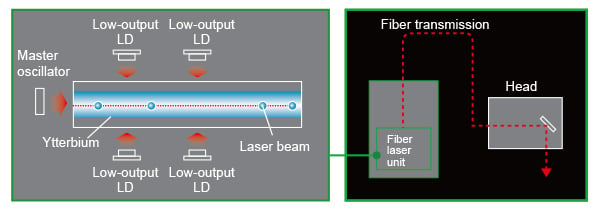

What is FAYb laser?

In a revolutionary method, the FAYb laser amplifies a weak laser beam from a master oscillator as it passes through a fiber treated with the element ytterbium to emit a strong laser beam.

Long life and high reliability

The LD contains reliable and durable InGaAs (gallium indium arsenide). Since the LD lights only during marking, the heat load remains minimal and the product provides a long life.

High efficiency and energy saving

Because laser amplification takes place inside the fiber containing ytterbium, high beam-to-beam conversion efficiency of pproximately 50 % is achieved.

Compact head

The amplification section is contained inside the oscillator unlike solid lasers such as YVO4, so the head is compact and contributes to the reduction of equipment size.

Compact fan-less head with IP64 rating

The head was developed based on the fan-less head equipped in the LP-M series, so it is tough. There will be no entry of water drop and dust particles to cause problems.

No more cumbersome installation work

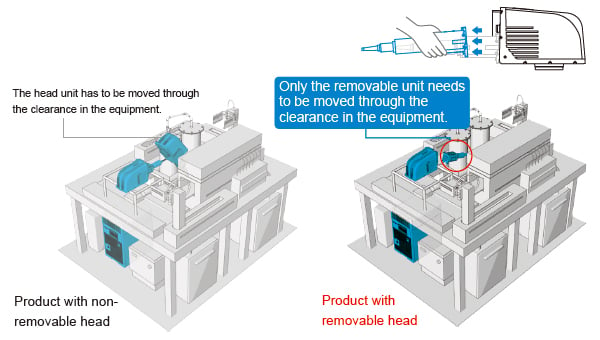

Removable head

With a conventional model, the head cannot be separated from the controller.

Therefore, installation or maintenance work requires the handling of the head that weighs more than 10 kg. The LP-RF series features a removable head, thus allowing the installation of the controller and head individually. This contributes to the reduction of man-hours required for installation and maintenance.

Measure against power supply noise

Electrical noise produced by equipment using a large amount of electrical current or generated in the surrounding area can affect the operation of the internal parts of the equipment and causes problems. Therefore, UPSs (uninterruptible power supply units) are installed to equipment in many production facilities as a measure against power supply noise. The laser marker controller of the LP-RF series is equipped with anti-noise parts such as a power transformer and varistor to ensure safe and reliable use of the laser marker on the production floor. This protects the internal parts of the laser marker from electrical noise and prevents problems caused by noise.

Direct linkage with image processing device

Automatic marking position correction and scan check

The LP-RF series can be connected directly to the PV230 series machine vision system.

This enables the execution of a series of operations, such as detection of the position of approximately placed workpiece, correction of the laser irradiation position, laser marking, and cross-checking of scanned information of marked QR code, etc., without using a PLC.

|

|

| |||||||||

Safety consideration

Duplicate interlock circuit

The interlock circuit using a contactor features a duplicate configuration. It reliably shuts off the laser power source unit in the event an abnormality occurs. In addition, the LP-RF series is complete with safety features such as the broken line notification function and erroneous irradiation detection function.

Laser marking of design image in a simple way

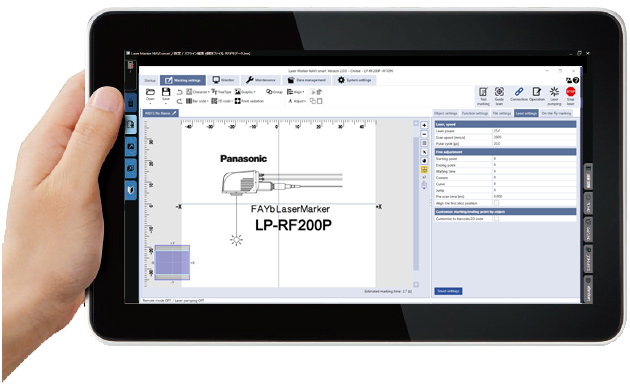

Laser Marker NAVI Smart

The new "Laser Marker NAVI Smart" software, which was supplied with the LP-GS CO2 laser marker and highly acclaimed, is provided with the product. Using the software, characters and logo marks and 2D code can be set and arranged on a PC or tablet. The screen layout can be customized to suit each work environment. The screen can be switched according to the purpose of use, such as for parameter setting or for workers.

Simple 3-step setting

(1) Arrange the characters and figures to be marked.

|

|

|

Navigation for attaining optimal marking result

Smart condition setting function

The one-touch function is packed with our extensive know-how of laser marking parameters such as laser power, scan speed and pulse oscillation frequency. The user can select a desired marking result from 16 types of material and image.

|

|

| ||||||

|

|

| ||||||

PP

(black)

* Installation of Adobe® Illustrator® (for Windows) is required for the use of the plug-in.Regarding the supported versions of Adobe® Illustrator®, contact our company.

The supplied plug-in software converts AI data prepared with Adobe® Illustrator®* to marking data for use by the laser marker. This lets the user to flexibly design the characters to be marked.

------------------------------ Tab2 showing ------------------------------

Applications

Bearing

Gear

Battery pack

Tool

Camshaft

Sheath cutting

Cleaning process

------------------------------ Tab3 showing ------------------------------

------------------------------ Tab4 showing ------------------------------

Specifications

| Model No. | LP-RF200P | |

|---|---|---|

| Marking laser | Laser type | Yb fiber laser; λ= 1,064 nm 0.0419 mil Class4 laser |

| Average oscillator output | 20 W | |

| Average output at processing point (Note 1) | 17 W (±5 %) Pulse oscillation (Pulse cycle: 5 μs to 50 μs) | |

| Guide laser / pointer | Red semiconductor laser; λ= 655 nm 0.026 mil; Class 2 laser: Maximum output 1 mW or less | |

| Scanning method | Galvano scanning method | |

| Marking field | 90 mm × 90 mm 3.543 in × 3.543 in | |

| Work distance (Note 2) | 190 mm 7.480 in | |

| Scan speed (Note 3, 4) | Maximum 12,000 mm/sec. 472.441 in/sec. | |

| Compatible line speed (Note 4) | Maximum 240 m/min. 787.402 ft/min. | |

| Character | English uppercase letters, English lowercase letters, numerals, katakana, hiragana, kanji (JIS level-1 and level-2), symbols, user-registered characters (up to 50), True type Simplified Chinese characters: GB 2312 level-1 and level-2 | |

| Bar code | CODE39,CODE93, CODE128 (GS1-128), ITF, NW-7, EAN/UPC/JAN GS1 DataBar Limited, GS1 DataBar Stacked, GS1 DataBar Limited CC-A, GS1 DataBar Stacked CC-A | |

| 2D code | QR Code, Micro QR Code, iQR Code, Data Matrix, GS1 Data Matrix, PDF417 | |

| Figure data (Note 5) | VEC, DXF, HPGL, BMP, JPEG, AI, EPS | |

| Input / output port | I/O terminal block (40 pins), I/O connector (40 pins) | |

| Interface | EIA-RS-232C, Ethernet, EtherNet/IP (Note 6, 7), PROFINET (Note 6, 7) | |

| Cooling method | Head: Naturally air cooling, Controller: Forced air cooling | |

| Power supply (Note 8) | 180-264 V AC (including power voltage fluctuation of ±10 %), 50/60 Hz | |

| Power consumption (Note 9) | 370 VA or less (2.1 A or less) | |

| Protection | Head: IP64 | |

| Ambient temperature (Note 10, 11) | 0 to +40 ℃ +32 to +104℉ | |

| Ambient temperature for storage (Note 10) | -10 to +60 ℃ +14 to +140 | |

| Ambient humidity (Note 10) | 35 to 85 % RH | |

| Net weight | Head | 8 kg approx. |

| Controller | 37 kg approx. | |

| Applicable regulations and certifications | FDA Regulations, CE Marking [Machinery Directive (Declaration of Incorporation), EMC Directive, RoHS Directive], UKCA Marking [Supply of Machinery (Safety) Regulations (Declaration of Incorporation), EMC Regulations, RoHS Regulations], Chinese Standard GB 7247.1 | |

| Supplied software | Laser Marker Smart Utility (Laser Marker NAVI Smart, logo data editing software, ExportVec, font maker software) | |

| Laser Marker NAVI smart display language | Japanese, English, Simplified Chinese, Traditional Chinese, German, Korean | |

| OS supported by the supplied software (Note 12, 13) | Windows® 10 Pro (32 bit, 64 bit), Windows® 8.1 Pro (32 bit, 64 bit) | |

Notes:

1) This indicates the output power at processing point when maximum power is set. (Factory default)

2) There may be an individual difference of approximately ±0.5 mm ±0.02 in in the work distance.

3) The indicated values show the allowable setting range. The setting values that can maintain the marking / processing quality vary depending on the marking condition and target material.

4) Depending on the setting data, the scan speed may be subject to upper-limit restriction in some cases.

5) VEC is a figure file format designed exclusively for laser markers. If figure files in the AI or EPS format are used, they must be converted to VEC-format files in advance using the ExportVEC software provided with the product.

6) Please prepare optional items separately for communication.

LP-ANW10: EtherNet/IP, LP-ANW11: PROFINET

EtherNet/IP is a registered trademark of ODVA (Open DeviceNet Vender Association, Inc.).

PROFINET is a registered trademark of PROFIBUS & PROFINET INTERNATIONAL.

7) Supported from the production in September 2019.

8) Frequency is selected and set automatically.

9) The rush current (typical value) at startup is as follows: 220 V AC (current flowing time of 10 ms or less): 50 A

10) Common to the controller and head. There must be no dew condensation or icing.

11) Laser power setting of 46 or higher: 0 to +36 ℃ +32 to +97 ℉,

Laser power setting of 1 to 45: 0 to 40 ℃ 32 to 104 ℉

12) Microsoft and Windows are registered trademarks or trademarks of Microsoft Corporation in the United States and other countries.

13) OS versions of which Microsoft has ended support are excluded.

PRECAUTIONS FOR PROPER USE

・This catalog is a guide to select a suitable product. Be sure to read instruction manual attached to the product prior to its use.

- This product is classified as a Class 4 Laser Product in IEC / JIS / FDA* regulations 21 CFR 1040.10 and 1040.11. Never look at or touch the direct laser beam and its reflection.

- The laser used by this product generates infrared light that is invisible to the human eye. Use particular caution when the laser is operating.

- The following labels are attached to the LP-RF series. Handle the product according to the instruction given on the warning labels. (Warning labels are not shown in the product photographs in this catalog.)

No. 50, dated June 24, 2007, issued by CDRH.

Safety standards for laser beam products

- A laser beam can harm human being’s eyes, skin, etc., because of its high energy density. IEC has classified laser products according to the degree of hazard and the stipulated safety requirements.

The LP-RF series are classified as Class 4 laser.

Overview of classification by IEC 60825-1

| Classification | Description |

|---|---|

| Class 4 | Lasers that are also capable of producing hazardous diffuse reflections. They may cause skin injuries and could also constitute a fire hazard. |

Safe use of laser products

Recommended use of a dust collector

* For more information, contact our office.

- For the purpose of preventing user from suffering injuries by laser products, IEC 60825-1 (Safety of laser products).

Kindly check the standards before use.

------------------------------ Tab5 showing ------------------------------

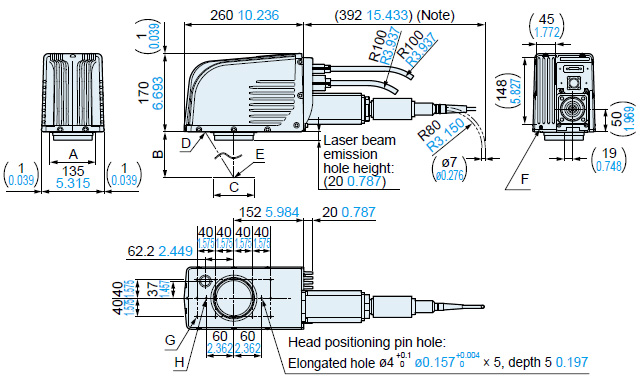

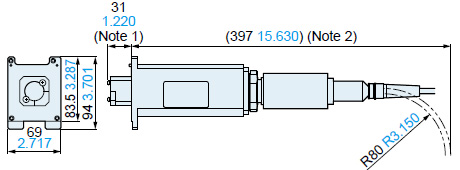

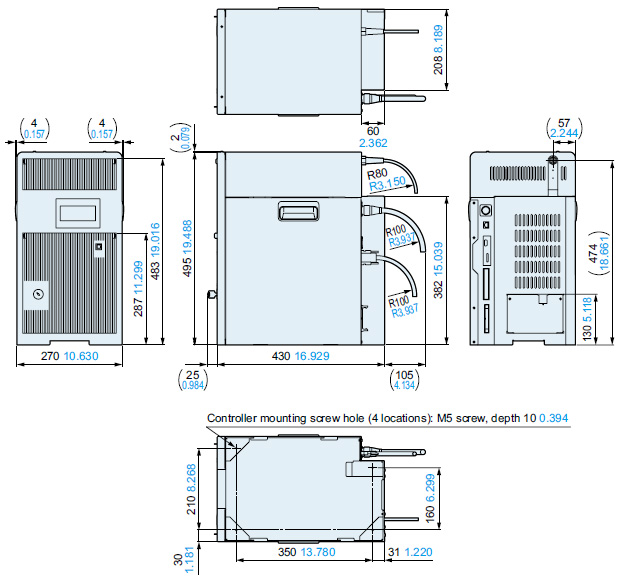

Dimensions

- Unit: mm in

Head

A:Laser beam emission port diameter (protruded section): ø100ø3.937

B:Work distance: 1907.480

C:Marking field (X, Y): 90 × 903.543 × 3.543

D:Laser pointer beam emission port diameter : ø26ø1.024(lens section: ø20ø0.787)

E:Center of marking area

F:Frame grounding screw: M4 screw, depth 50.197

G:Head mounting screw hole (10 locations*): M6 screw, depth 60.236*Use six or more screws to mount the head

H:Head positioning pin hole:ø4+0.10ø0.157+0.0040depth 50.197

(Note 1) :Production before August 2021 is 377 mm14.843 inch.

Fiber unit

With fiber unit removed

(Note 2) :Production before August 2021 is 46 mm1.811 inch.

(Note 3) :Production before August 2021 is 382 mm15.039 inch.

Controller

* AC power cable is not attached to the laser marker body. (Sold separately)