DC Fan Motor 80 x 25t(ASFN8) (Discontinued Products)

Download

-

Discontinued Products

-

Specifications

-

Dimensions

-

Cautions For Use

Ⅾiscontinued

Last time buy (JST)

September 30, 2021

Discontinued Products

Specifications

SPECIFICATIONS

| Ambient temperature | -10℃ to +60℃ +14℉ to +140℉ | |

|---|---|---|

| Humidity resistance test condition | 40 ℃ 104 ℉, 95% RH, 500 hrs. | |

| Temperature rise | Coil surface: Max. 50℃ 122℉ (Nominal voltage, by resistive method) External surface:M ax. 20℃ 68℉ (Nominal voltage, by thermocouple method) | |

| Breakdown voltage | 500 V AC for 1 min. (between lead wire and external housing) | |

| Insulation resistance | Min. 10 MΩ (at 500 V DC) | |

| Vibration resistance | Frequency | 10 to 55Hz |

| Double amplitude width | 0.75mm | |

| Applied direction | X, Y and Z directions | |

| Applied time | 10 min. in each direction | |

| Lead wire tensile strength | 9.8 N, single wires did not break at 15 seconds | |

| Fan blockage | No coil burnout even after blockage of 72 hrs. at nominal voltage. | |

| Reverse polarity power connection | No damage even after reverse polarity connection for short time at nominal voltage. | |

| Expected life | 90% survival rate at 60,000 hrs. (When rotation frequency drops 30% of initial value when run at nominal voltage under 25℃ 77℉, room humidity.) | |

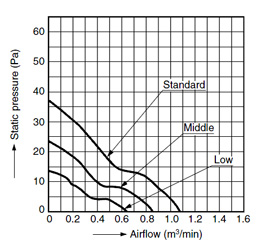

DATA (Airflow - Static pressure Characteristic Curve)

MATERIALS USED

| Frame | plastic |

|---|---|

| Propeller | plastic |

| Bearings | ball bearings |

| Lead wires | UL1007 and AWG24 |

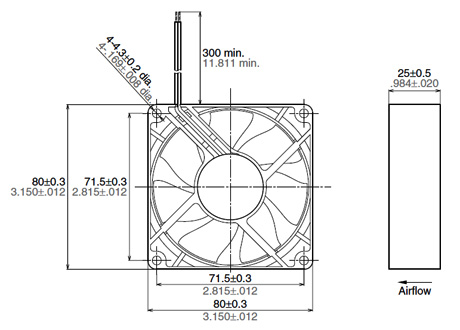

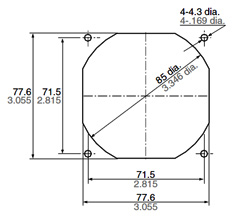

Dimensions

- Unit: mm in

ASFN8

Discharge side / Suction side

Cautions For Use

DC fan motor

- Do not reverse-connect the power supply. Although nothing adverse will occur if the rated voltage is connected in reverse for a short time period, the fan will not operate.

- If the power is to be pulsed on and off in order to start and stop the fan quickly, be sure to install a switch on the + side of the power supply. Not doing so may damage the circuit.

DC fan motor and AC fan motor

- Since our fan motor employs precision ball bearings, due care should be taken not to apply any shock in handling.

- Due to the bearing mechanism, the noise level will increase in proportion to the length of time the fan is used.

Avoid use where the temperature is high or where there is a lot of dirt. - Do not allow substances such as oil and grease to get onto the plastic part of the fan body. Some oils and greases decompose and become altered at high temperatures. These can have an adverse effect if they contact the fan.

Therefore, be very careful when handling these substances. - Do not apply unnecessary force to the internal parts when handling the product. Also, do not use a fan that has been dropped.

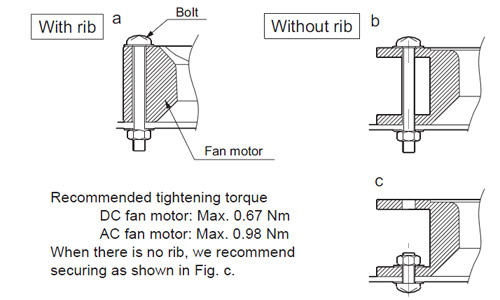

- Installation

Install according to the diagrams below.

- Fan life is based on usage at room temperature and a humidity of 15 to 45 % RH. Please verify life under actual conditions, since life will depend on the frequency and duration of use, as well as the atmosphere in which it is used.

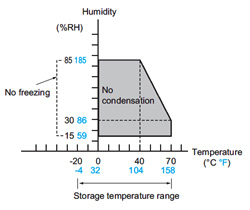

- Transport and storage conditions

The allowable specifications for environments suitable for transportation and storage are given below.

・No freezing between -20 ℃ to 0 ℃ -4 ℉ to +32 ℉

・No condensation in the range above between 0 ℃ to +70 ℃ +32 ℉ to +158 ℉ - Condensation

If the temperature is high and there is a lot of humidity, condensation will occur when the temperature suddenly changes.

This should be avoided because it can cause degradation of the fan insulation. - Freezing

At temperatures 0 ℃ +32 ℉ moisture such as that caused by condensation will freeze and lead to problems such as lockage of the moving parts and operation lags. Be careful to prevent this from happening. - Low-temperature, low-humidity environments

Do not leave the fan for a long period in an environment of low temperature and low humidity. Doing so may cause the plastic to become brittle. - When storing, avoid places of high temperature and high humidity or where corrosive gas is present.

- Do not store the fan any longer than six months.

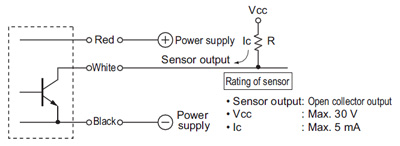

FUNCTIONS OF DC FAN SENSOR

In case of the fan stops as a result of forced external restraint, a signal will be generated to indicate that there is a problem. This signal can be used to control an external warning circuit in order to help prevent the device from overheating. Although there are various detection methods for this sensor, we adopt the method that uses a logic circuit.

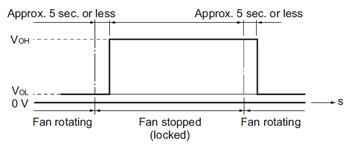

1.Lock sensor specifications

Output waveform

*Output may be high for approximately 0.5 seconds when power is turned on.

*The continually high output waveform type when fan is stopped (locked) is standard. A high/low output waveform type and output waveform type that corresponds to the rotation frequency during fan rotation are available by special order. Please inquire for details.

2.Sensor output circuit

Note 1:Set the resistance value (R) so that the sensor circuit current (Ic) does not exceed 5 mA.

Note 2:When using at TTL level, the sensor circuit current (Ic) should be approximately 2 mA.

* Exceeding the values above may lead to IC damage.