Optical Touch Switch SW-100

Download

-

Basic Information

-

Order guide

-

Option

-

Specifications

-

Dimensions

-

Circuit/ Wiring

-

Cautions For Use

Basic Information

Gentle start-up switches in accordance with ergonomics

CE : EMC Directive

UKCA : EMC Regulations

Contact Us

Features

Greater convenience with less stress on the hands.

Inventive start-up switches in accordance with ergonomics. [SW-101]

![Greater convenience with less stress on the hands. Inventive start-up switches in accordance with ergonomics. [SW-101]](https://test-test-test-tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/safety/sw-101/images/pic02.jpg)

Reduction in false operation from dropped objects [SW-101]

The response time is set for a slight delay so that the switch will not respond a falling object, such as a dropped tool. The switch is designed so that it will operate when touched by hand, but false operation will rarely occur when something is dropped onto it.

![Reduction in false operation from dropped objects [SW-101]](https://test-test-test-tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/safety/sw-101/images/pic03.jpg)

A switch that pursues the prevention requirement for malfunctioning as required by ISO 13851 (JIS B 9712) two-hand control devices [SW-111]

![A switch that pursues the prevention requirement for malfunctioning as required by ISO 13851 (JIS B 9712) two-hand control devices [SW-111]](https://test-test-test-tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/safety/sw-101/images/pic04.jpg)

Safeguard prevents false operation

SW-111 saves the hassle of making an additional safeguard. In addition, with its ISO 13851 complying shape, even a knock on the elbow will not cause a false operation (light interruption).

Intended startup is possible [SW-111]

SW-111's detection does not operate when a hand is just placed onto the unit.

With a design that only detects when fingers are bent in and lightly grip onto the unit, an intended startup is possible.

![Intended startup is possible [SW-111]](https://ap.industry.panasonic.com/hubfs/pid-corp/products/fasys/sensor/safety/sw-101/images/pic06.jpg)

Equipped with external input indicators

Two sets of external input indicators (two colors) are provided, so that they can be used as operation indicators for a variety of purposes.

Prevents false operation caused by dirt

If the light is continuously interrupted for more than 10 sec. by dust, etc., the switch is disabled and the fault indicator (yellow) illuminates.

Uses a long-life Photo-MOS relay

Because a Photo-MOS relay is used for the output, a single unit can be configured without a specific output polarity.

In addition, there is no need for periodic replacement of parts such as contact-type relays.

Option

| Designation | Model No. | Description |

|---|---|---|

| Mounting tool | SW-MT1 | Tool for tightening mounting nuts with a commercially-available wrench. |

| Sensing surface protective sheet for SW-101 | SW-PS1 | A transparent stick-on sheet that protects the sensing surface of SW-101 from dirt and scratches. [5 sheets per set] |

Mounting tool

SW-MT1

Sensing surface protective sheet for SW101

Specifications

| Designation | Optical touch switch | ||

|---|---|---|---|

| With safeguard | |||

| Model No. | SW-101 | SW-111 | |

| Sensing method | Thru-beam type photoelectric sensor (2 beam axes) | ||

| Applicable standards | CSA 22.2 No.14, CSA 22.2 No.0.8, ANSI / NFPA 79, UL 508, EN 60947-5-2 (EMC only) | ||

| Power supply | 12 to 24 V DC ±10 % Ripple P-P 10 % or less | ||

| Current consumption | 100 mA or less (excluding external connection load) | ||

| Outputs | Semiconductor Photo-MOS relay output x 3 • Maximum load current: 100 mA • Applied voltage: 30 V DC or less (between output and +V) • Residual voltage: 1.5 V or less (at 100 mA of load current) | ||

| Output operation | Output 1 : When an object is detected (beam is interrupted): OFF / When an object is not detected (beam is received): ON Output 2, 3 : When an object is detected (beam is interrupted): ON / When an object is not detected (beam is received): OFF | ||

| Short-circuit protection | Incorporated | ||

| Response time | 100 ms or less when an object is detected, 50 ms or less when an object is not detected | ||

| Time-out function | Switchable either effective or ineffective by short-circuiting terminals (disabled when short-circuited) | ||

| External input | 0 to 1 V or 10 V to +V: Valid (External input indicator lights up), 4 to 6 V or Open: Invalid (External input indicator lights off) | ||

| Indicators | Power indicator (POWER) | Green LED (lights up when the power is ON) | |

| Operation indicator (OPE.) | Green LED (lights up when an object is detected) | ||

| External input indicator 1 | Green LED (lights up when external input 1 is valid) | ||

| External input indicator 2 | Orange LED (lights up when external input 2 is valid) | ||

| Fault indicator (FAULT) | Yellow LED (blinks or lights up when fault occurs) | ||

| Protection | IP65 (IEC), TYPE 1 (UL 50) (excluding terminal part) | ||

| Ambient temperature | −25 to +50 ℃ −13 to +122 ℉ (No dew condensation or icing allowed), Storage: −30 to +70 ℃ −22 to +158 ℉ | ||

| Ambient humidity | 30 to 85 % RH, Storage: 30 to 85 % RH | ||

| Ambient illuminance | Incandescent light: 3,000 Lx or less at the light-receiving face | ||

| Voltage withstandability | 1,000 V AC for one min. between all supply terminals connected together and enclosure | ||

| Insulation resistance | 20 MΩ, or more, with 500 V DC megger between all supply terminals connected together and enclosure | ||

| Vibration resistance | 10 to 500 Hz frequency, 3 mm 0.118 in double amplitude in X, Y and Z directions for two hours each | 10 to 150 Hz frequency, 0.75 mm 0.030 in double amplitude in X, Y and Z directions for two hours each | |

| Shock resistance | 500 m/s2 acceleration (50 G approx.) in X, Y and Z directions three times each | ||

| Removable-type terminals | Connector | 3.5 mm 0.138 in pitch, 2-level socket: 12 pins | |

| Terminal part | 3.5 mm 0.138 in pitch spring-cage terminals: 6 pins x 2 (FMC1,5/6-ST-3,5GS manufactured by Phoenix Contact) | ||

| Cable | 0.2 to 1.5 mm2 [including single wire or ferrule (sleeve)] | ||

| Maximum cable length | Up to 20 m 65.617 ft (for cable from 0.2 to 0.3 mm2), Up to 100 m 328.084 ft (for cable from 0.3 to 1.5 mm2) | ||

| Material | Enclosure: Polycarbonate, Polyester, O-ring: Silicone rubber, Mounting nut: PBT, Mounting packing: Silicone rubber | ||

| Weight | Net weight: 130 g approx., Gross weight: 200 g approx. | Net weight: 150 g approx., Gross weight: 220 g approx. | |

Note:

Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +23 ℃ +73.4 ℉.

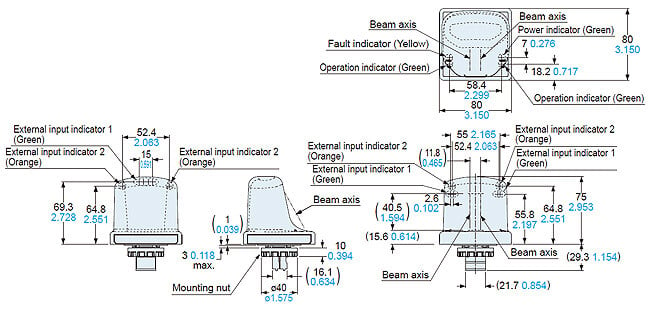

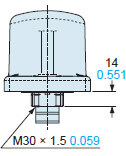

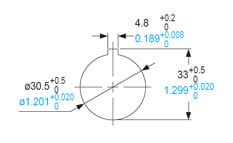

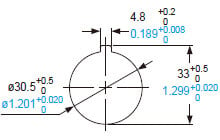

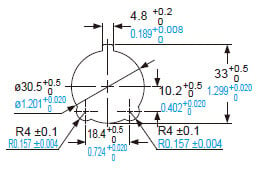

Dimensions

- Unit: mm in

SW-101

Diagram without mounting nuts installed

Panel cut-out dimensions

<When mounting with a resin plate>

<When mounting with a metal plate>

Note:The panel thickness should be 3 mm 0.118 in or less.

SW-111

Diagram without mounting nuts installed

Panel cut-out dimensions

<When mounting with a resin plate>

<When mounting with a metal plate>

Note:The panel thickness should be 3 mm 0.118 in or less.

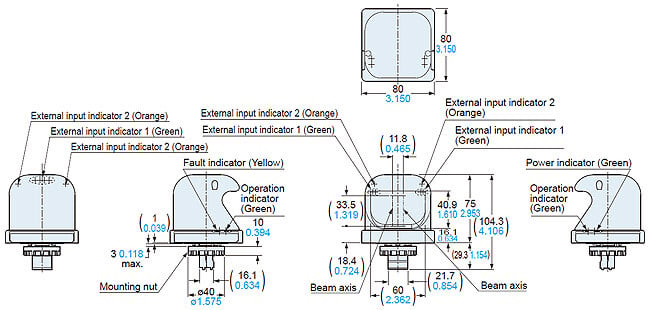

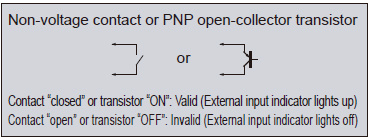

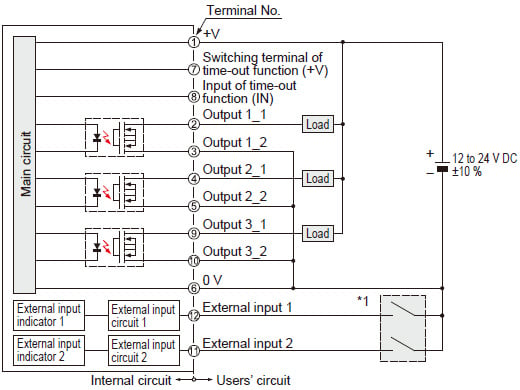

I/O Circuit and Wiring diagrams

I/O circuit diagram

If case of connecting output to Minus common

*1

If case of connecting output to Plus common

*1

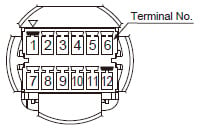

Terminal arrangement diagram

Cautions For Use

- Never use this product in a device for personnel protection.

- In case of using devices for personnel protection, use products which meet laws and standards, such as OSHA, ANSI or IEC etc., for personnel protection applicable in each region or country.

- Do not use this product as a device for emergency stop.

- This product is used to start up the machinery. Securing safety for the startup of machinery should be performed separately.

- When using the products for two-hand control, comply with the following contents.

- Select a model of a control device for two-hand control, based on results of risk assessment.

- Make sure to use a controller for two-hand control which complies with ISO 13851 (EN 574, JIS B 9712)

- For another requirements such as mounting of this product, or prevention of accidental actuation and of defeat etc., comply with ISO 13851 (EN 574, JIS B 9712) and ANSI B11.1, B11.9. Furthermore, comply with the regulations established by national or regional security committees (Occupational Safety and Health Administration: OSHA, the European Standardization Committee, etc.)

Mounting

- Fasten a mounting nut (accessory) from the reverse side of the mounting plate.(Note 1)

The tightening torque should be 2 to 3 N·m.

Notes:

1) A mounting tool (SW-MT1) for fastening the mounting nut is available separately. The shape of fastening part of SW-MT1 is M10 nut.

2) Make sure to use the attached mounting packing, or waterproof property will be invalid.

Time-out function

- Unintended beam interrupted status caused by dirt on the sensing surface, etc. can be monitored.

When beam interrupted status (sensing status) continues for 10 sec. or more, output 1 turns ON and output 2 and 3 turn OFF (output status is the same as non-sensing status.)

This function can be invalid by short-circuiting “between switching terminals of time-out function (terminal No. 7 and No. 8)” as described below.

Note : When time-out function is operated, the fault indicator (yellow) lights up. In this case, once beam is received, the fault indicator lights off and the sensor returns to normal operation.

Others

- This device has been developed / produced for industrial use only.

- This product is suitable for indoor use only.

- When the power of the thru-beam type photoelectric sensor inside the main body turns on in beam interrupted status, output 1 turns ON and output 2 and 3 turn OFF, then the fault indicator (yellow) lights up. In this case, once beam is received, the fault indicator lights off and the sensor returns to normal operation.

- Use a power supply unit conforming to the EMC Directive and the Low Voltage Directive. (Only for use in Europe)

- Use a power supply unit conforming to Class 2. (Only for use in the North America)

- Use a power supply unit with an output holding time of 20 ms or more.

- Do not use during the initial transient time (300 ms approx.) after the power supply is switched on.