Compact Inductive Proximity Sensor GA-311/GH

Download

-

Basic Information

-

Applications

-

Order guide

-

Option

-

Specifications

-

Dimensions

-

Circuit/ Wiring

-

Sensing characteristics

-

Cautions For Use

Basic Information

High-speed response and excellent workability

UL : Recognition

Contact Us

Features

Suitable for high-speed applications

It has a high performance of 3.3 kHz response frequency.

These sensors are ideal for sensing objects moving at high speeds.

IP67G sensor head variations

The lineup includes 5 different models, from an ultracompact 2.8 mm 0.110 in diameter type to a spatterresistant type. Furthermore, all except for the GH-2SE are IP67G oil-resistant models so that they can be used with confidence even in adverse environments.

Excellent workability and ease of maintenance

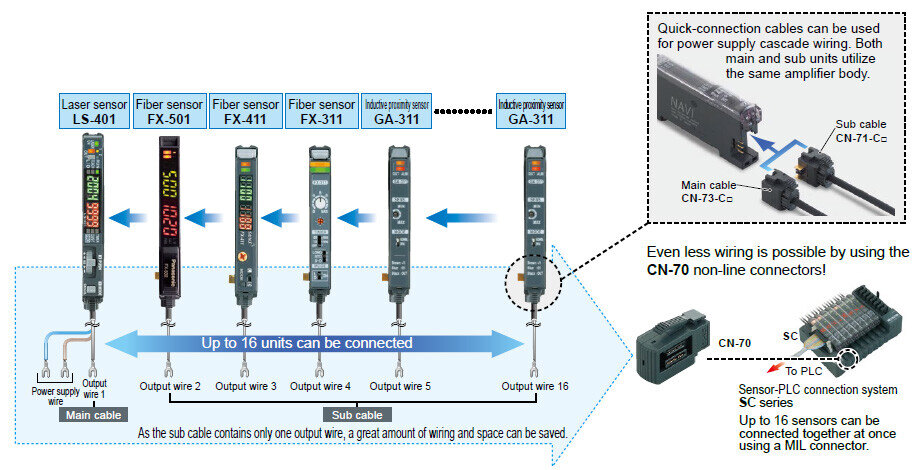

It uses a quick-connection cable that is used in digital fiber sensors. It can be used in combination with fiber sensors and laser sensors, and can reduce the wiring of the power supply.

Labor-saving by one-touch connections

The connection between the sensor head and the amplifier is made using a quick-connection connector.

Past troublesome wiring connections using a screwdriver are no longer necessary.

Disconnection alarm indicator and operation indicator have been incorporated

Applications

Order guide

Sensor heads

| Type | Appearance (mm in) | Sensing range (Note) | Model No. | Hysteresis | ||

|---|---|---|---|---|---|---|

| Maximum operation distance | Stable sensing range | |||||

| Cylindrical type |

| 1.2mm 0.047 in | 0 to 0.6 mm 0 to 0.024 in | GH-2SE | 0.07 mm 0.0028 in or less | |

| 1.8mm 0.071 in | 0 to 0.8 mm 0 to 0.031 in | GH-3SE | 0.05 mm 0.0020 in or less | ||

| 2.4mm 0.094 in | 0 to 1.0 mm 0 to 0.039 in | GH-5SE | |||

| 4.0mm 0.157 in | 0 to 2.0 mm 0 to 0.079 in | GH-8SE | 0.04 mm 0.0016 in or less | ||

| Spatter resistant type | GH-F8SE | |||||

Note : The stable sensing range represents the sensing range for which the sensor can satisfy all the given specifications with the standard sensing object.

The maximum operation distance represents the maximum distance for which the sensor can detect the standard sensing object at +20 ℃ +68 ℉ constant ambient temperature.

Usage within the stable sensing range is recommended for accurate sensing applications.

Due to the characteristics of the potentiometer, it may be difficult to adjust the sensitivity at short distances.

Amplifier

Quick-connection cable is not supplied with the amplifier. Please order it separately.

| Type | Appearance | Model No. | Output |

|---|---|---|---|

| Connector type |

| GA-311 | NPN open-collector transistor |

Quick-connection cable

Quick-connection cable is not supplied with the amplifier. Please order it separately.

| Type | Model No. | Description | |

|---|---|---|---|

| Main cable (3-core) | CN-73-C1 | Length: 1 m 3.281 ft | 0.2 mm2 3-core cabtyre cable, with connector on one end Cable outer diameter: ø3.3 mm ø0.130 in |

| CN-73-C2 | Length: 2 m 6.562 ft | ||

| CN-73-C5 | Length: 5 m 16.404 ft | ||

| Sub cable (1-core) | CN-71-C1 | Length: 1 m 3.281 ft | 0.2 mm2 1-core cabtyre cable, with connector on one end Cable outer diameter: ø3.3 mm ø0.130 in |

| CN-71-C2 | Length: 2 m 6.562 ft | ||

| CN-71-C5 | Length: 5 m 16.404 ft | ||

(Note): The material of Quick-connection cable will be changed from production in March 2013, as soon as the previous ones are shipped out.

・Conductor cross-sectional area has been changed from 0.15mm2 to 0.2mm2.

・Sheath diameter has been changed from ø3.0mm to ø3.3mm.

Main cable

CN-73-C口

Sub cable

CN-71-C口

End plates

End plates are not supplied with the amplifier. Please order them separately when the amplifiers are mounted in cascade.

| Appearance | Model No. | Description |

|---|---|---|

| MS-DIN-E | When cascading multiple amplifiers, or when it moves depending on the way it is installed on a DIN rail, these end plates clamp amplifiers into place on both sides. Make sure to use end plates when cascading multiple amplifiers together. [ 2 pcs. per set ] |

Amplifier mounting bracket

MS-DIN-2

Sensor head mounting bracket

MS-SS口

Specifications

Sensor heads

| Type | Cylindrical type | |||||

|---|---|---|---|---|---|---|

| Spatter- resistant type | ||||||

| Model No. | GH-2SE | GH-3SE | GH-5SE | GH-8SE | GH-F8SE | |

| Applicable amplifier | GA-311 | |||||

| Stable sensing range (Note 2) | 0 to 0.6 mm 0 to 0.024 in | 0 to 0.8 mm 0 to 0.031 in | 0 to 1.0 mm 0 to 0.039 in | 0 to 2.0 mm 0 to 0.079 in | ||

| Max. operation distance (Note 2) | 1.2 mm 0.047 in | 1.8 mm 0.071 in | 2.4 mm 0.094 in | 4.0 mm 0.157 in | ||

| Standard sensing object | Iron sheet 5 × 5 × t 1 mm 0.197 × 0.197 × t 0.039 in | Iron sheet 10 × 10 × t 1 mm 0.394 × 0.394 × t 0.039 in | ||||

| Hysteresis (Note 3) | 0.07 mm 0.003 in or less | 0.05 mm 0.002 in or less | 0.04 mm 0.002 in or less | |||

| Repeatability (Note 3) | Along sensing axis, perpendicular to sensing axis: 1 μm 0.039 mil or less | |||||

| Protection | IP50 (IEC) | IP67 (IEC), IP67G (Note 4) | ||||

| Ambient temperature | -10 to +60 ℃ 14 to +140 ℉, Storage: -20 to +70 ℃ -4 to +158 ℉ | |||||

| Ambient humidity | 35 to 85 % RH, Storage: 35 to 85 % RH | |||||

| Vibration resistance | 10 to 55 Hz frequency, 1.5 mm 0.059 in double amplitude in X, Y and Z directions for two hours each | |||||

| Shock resistance | 500 m/s2 acceleration (50 G approx.) in X, Y and Z directions five times each | |||||

| Temperature characteristics (Note 5) | Within ±7 % | Within ±5 % | Within ±4 % | |||

| Material | Enclosure: Stainless steel (SUS303) Sensing part: PVC | Enclosure: Stainless steel (SUS303) Sensing part: ABS | Enclosure: Stainless steel (SUS303) Sensing part: PAR | Enclosure: Stainless steel (SUS303) Sensing part: ABS | Enclosure: Stainless steel (SUS303) Sensing part: Fluorine resin | |

| Cable (Note 6) | Oil-resistant [Spatter-resistant type: Spatter-resistant cable (Sheath: Fluorine resin)] high-frequency coaxial cable, 3 m 9.843 ft long, with a connector at the end | |||||

| Weight | Net weight: 15 g approx. Gross weight: 30 g approx. | Net weight: 35 g approx. Gross weight: 45 g approx. | Net weight: 40 g approx. Gross weight: 55 g approx. | Net weight: 55 g approx. Gross weight: 70 g approx. | ||

Notes:

1) Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +23 ℃ +73.4 ℉.

2) The stable sensing range represents the sensing range for which the sensor can satisfy all the given specifications with the standard sensing object.

The maximum operation distance represents the maximum distance for which the sensor can detect the standard sensing object at +20 ℃ +68 ℉ constant ambient temperature.

Usage within the stable sensing range is recommended for accurate sensing applications.

Due to the characteristics of the potentiometer, it may be difficult to adjust the sensitivity at short distances.

3) The hysteresis and the repeatability are specified for the standard sensing object within the stable sensing range.

4) The length of the sensor head cable cannot be changed.

5) If using the sensor in an environment where cutting oil droplets splatter, the sensor may deteriorate due to added substances in the oil.

Please check the resistivity of the sensor against the cutting oil you are using beforehand.

6) The value represents the variation in the operation distance, that has been set within the stable sensing range at +20 ℃ +68 ℉, for an ambient temperature drift from 0 to +55 ℃ +32 to +131 ℉. (Values are for sensor head only.)

Amplifier

| Model No. | GA-311 | |

|---|---|---|

| Applicable sensor head | GH-□SE | |

| Supply voltage | 12 to 24 V DC ± 10 % Ripple P-P 10 % or less | |

| Current consumption | 25 mA or less | |

| Output | NPN open-collector transistor ・Maximum sink current: 100 mA (50 mA, if five, or more, amplifiers are connected in cascade.) ・Applied voltage: 30 V DC or less (between sensing output and 0 V) ・Residual voltage: 1 V or less [at 100 mA (at 50 mA, if five, or more, amplifiers are connected in cascade) sink current.] | |

| Output operation | Switchable either Normally open or Normally closed | |

| Short-circuit protection | Incorporated | |

| Max. response frequency | 3.3 kHz | |

| Operation indicator | Orange LED (lights up when the output is ON) | |

| Disconnection alarm indicator | Red LED (lights up when the sensor head cable is disconnected or misconnected) | |

| Sensitivity adjuster | 18-turn potentiometer | |

| Ambient temperature | -10 to +60 ℃ +14 to +140 ℉ (If 4 to 7 units are connected in cascade : -10 to +50 ℃ +14 to +122 ℉, if 8 to 16 units are connected in cascade: -10 to +45 ℃ +14 to +113 ℉) (No dew condensation or icing allowed), Storage: -20 to +70 ℃ -4 to +158 ℉ | |

| Ambient humidity | 35 to 85 % RH, Storage: 35 to 85 % RH | |

| Voltage withstandability | 1,000 V AC for one min. between all supply terminals connected together and enclosure | |

| Insulation resistance | 20 MΩ, or more, with 250 V DC megger between all supply terminals connected together and enclosure | |

| Vibration resistance | 10 to 150 Hz frequency, 0.75 mm double amplitude or maximum acceleration 49 m/s2 in X, Y, and Z direction for 2 hours each | |

| Shock resistance | 100 m/s2 acceleration (10 G approx.) in X, Y and Z directions three times each | |

| Temperature characteristics (Note 2) | Within ±5 % | |

| Material | Enclosure: PBT, Cover: Polycarbonate | |

| Connecting method | Connector (Note 3) | |

| Cable length | Total length up to 100 m 328.084 ft (if 5 to 8 units are connected in cascade: 50 m 164.042 ft, if 9 to 16 units are connected in cascade: 20 m 65.617 ft) is possible with 0.3 mm2, or more, cable. | |

| Weight | Net weight: 15 g approx., Gross weight: 40 g approx. | |

Notes:

1) Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +23 ℃ +73.4 ℉.

2) The value of the temperature characteristics gives the variation in the operation distance, that has been set within the stable sensing range at +20 ℃ +68 ℉, for an ambient temperature drift from 0 to +55 ℃ +32 to +131 ℉. (Value is for amplifier only.)

3) The cable for amplifier connection is not supplied as an accessory. Make sure to use the optional quick-connection cable given below.

Main cable (3-core): CN-73-C1 (cable length 1 m 3.281 ft), CN-73-C2 (cable length 2 m 6.562 ft), CN-73-C5 (cable length 5 m 16.404 ft)

Sub cable (1-core): CN-71-C1 (cable length 1 m 3.281 ft), CN-71-C2 (cable length 2 m 6.562 ft), CN-71-C5 (cable length 5 m 16.404 ft)

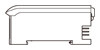

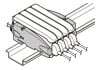

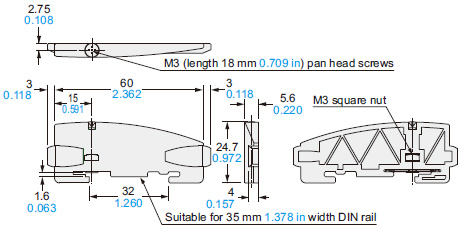

Dimensions

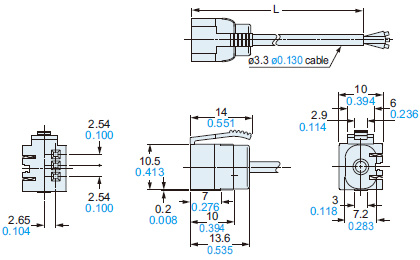

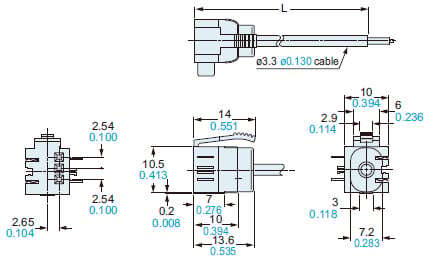

Unit: mm in

GA-311

Amplifier

Note:The front view shows the sensor head connector and quick-connection cable connector attached.The top view is without the sensor head connector, quick-connection cable and the cover.

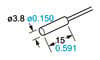

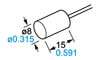

GH-2SE GH-3SE GH-5SE GH-8SE GH-F8SE

Sensor head

| Model No. | A | B | C |

|---|---|---|---|

| GH-2SE | ø2.8 ø0.110 | 12 0.472 | ø1.6 ø0.063 |

| GH-3SE | ø3.8 ø0.150 | 15 0.591 | ø2.5 ø0.098 |

| GH-5SE | ø5.4 ø0.213 | 15 0.591 | ø2.5 ø0.098 |

| GH-8SE | ø8.0 ø0.315 | 15 0.591 | ø2.5 ø0.098 |

| GH-F8SE | ø8.0 ø0.315 | 15 0.591 | ø2.65 ø0.104 |

CN-73-C1 CN-73-C2 CN-73-C5

Main cable (Optional)

• Length L

| Model No. | Length L |

|---|---|

| CN-73-C1 | 1,000 39.370 |

| CN-73-C2 | 2,000 78.740 |

| CN-73-C5 | 5,000 196.850 |

CN-71-C1 CN-71-C2 CN-71-C5

Sub cable (Optional)

• Length L

| Model No. | Length L |

|---|---|

| CN-71-C1 | 1,000 39.370 |

| CN-71-C2 | 2,000 78.740 |

| CN-71-C5 | 5,000 196.850 |

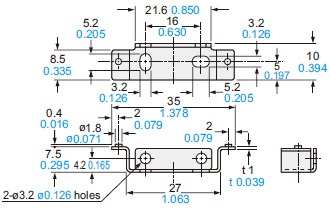

MS-DIN-2

Amplifier mounting bracket (Optional)

Material:Cold rolled carbon steel (SPCC) (Uni-chrome plated)

MS-DIN-E

End plate (Optional)

Material:Polycarbonate

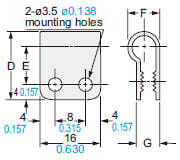

MS-SS3 MS-SS5 MS-SS8

Sensor head mounting bracket (Optional)

Material:Nylon 66

| Symbol | MS-SS3 | MS-SS5 | MS-SS8 |

|---|---|---|---|

| D | 16 0.630 | 18 0.709 | 20 0.787 |

| E | 9 0.354 | 10 0.394 | 11 0.433 |

| F | 6.3 0.248 | 8.3 0.327 | 10.3 0.406 |

| G | 4.9 0.193 | 6.1 0.240 | 6.5 0.256 |

| Applicable sensor head model No. | GH-3SE | GH-5SE | GH-8SE |

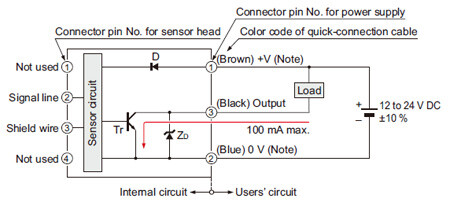

I/O Circuit and Wiring diagrams

I/O circuit diagram

Note: The quick-connection sub cable does not have +V (brown) and 0 V (blue). The power is supplied from the connector of the main cable.

Symbols・・・

D : Reverse supply polarity protection diode

ZD: Surge absorption zener diode

Tr : NPN output transistor

Wiring diagram

Note:The quick-connection sub cable does not have brown lead wire and blue lead wire.

Connector pin position

Sensing characteristics

(TYPICAL)

GH-2SE

The graph on the left is plotted with the sensitivity adjusted so as to just detect a 5 × 5 × t 1 mm 0.197 × 0.197 × t 0.039 in iron sheet placed at a distance of 0.6 mm 0.024 in.

As the sensing object size becomes smaller than the standard size (iron sheet 5 × 5 × t 1 mm 0.197 × 0.197 × t 0.039 in), the sensing range shortens as shown in the left figure.

(The graph on the left is plotted with the sensitivity adjusted so as to just detect a 5 × 5 × t 1 mm 0.197 × 0.197 × t 0.039 in iron sheet placed at a distance of 0.6 mm 0.024 in.)

GH-3SE

The graph on the left is plotted with the sensitivity adjusted so as to just detect a 5 × 5 × t 1 mm 0.197 × 0.197 × t 0.039 in iron sheet placed at a distance of 0.8 mm 0.031 in.

As the sensing object size becomes smaller than the standard size (iron sheet 5 × 5 × t 1 mm 0.197 × 0.197 × t 0.039 in), the sensing range shortens as shown in the left figure.

(The graph on the left is plotted with the sensitivity adjusted so as to just detect a 5 × 5 × t 1 mm 0.197 × 0.197 × t 0.039 in iron sheet placed at a distance of 0.8 mm 0.031 in.)

GH-5SE

The graph on the left is plotted with the sensitivity adjusted so as to just detect a 5 × 5 × t 1 mm 0.197 × 0.197 × t 0.039 in iron sheet placed at a distance of 1.0 mm 0.039 in.

As the sensing object size becomes smaller than the standard size (iron sheet 5 × 5 × t 1 mm 0.197 × 0.197 × t 0.039 in), the sensing range shortens as shown in the left figure.

(The graph on the left is plotted with the sensitivity adjusted so as to just detect a 5 × 5 × t 1 mm 0.197 × 0.197 × t 0.039 in iron sheet placed at a distance of 1.0 mm 0.039 in.)

GH-8SE GH-F8SE

The graph on the left is plotted with the sensitivity adjusted so as to just detect a 10 × 10 × t 1 mm 0.394 × 0.394 × t 0.039 in iron sheet placed at a distance of 2.0 mm 0.079 in.

As the sensing object size becomes smaller than the standard size iron sheet 10 × 10 × t 1 mm 0.394 × 0.394 × t 0.039 in), the sensing range shortens as shown in the left figure.

(The graph on the left is plotted with the sensitivity adjusted so as to just detect a 10 × 10 × t 1 mm 0.394 × 0.394 × t 0.039 in iron sheet placed at a distance of 2.0 mm 0.079 in.)

Cautions For Use

- Never use this product as a sensing device for personnel protection.

- In case of using sensing devices for personnel protection, use products which meet laws and standards, such as OSHA, ANSI or IEC etc., for personnel protection applicable in each region or country.

- Always be sure to use sensor heads and amplifiers from the same set

- Do not shorten or lengthen the sensor head cable.

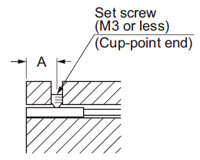

Mounting of the sensor head

How to mount the sensor head

- The tightening torque should be as given below. Make sure to use a set screw with a cup-point end.

| Model No. | Tightening torque | A (mm in) |

|---|---|---|

| GH-2SE | 0.17N·m | 3 0.118 or more |

| GH-3SE | 0.17N·m | 4 0.157 or more |

| GH-5SE | 0.78N·m | 5 0.197 or more |

| GH-8SE GH-F8SE | 0.59N·m | 5 0.197 or more |

Note: Do not tighten excessively.

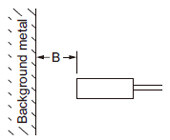

Distance from surrounding metal

- If there is a metal near the sensor head, it may affect the sensing performance.

Keep the minimum distance specified in the table below.

| Model No. | B (mm in) |

|---|---|

| GH-2SE | 3 0.118 |

| GH-3SE | 4 0.157 |

| GH-5SE | 5 0.197 |

| GH-8SE GH-F8SE | 9 0.354 |

Mutual interference

- When two or more sensors are installed in parallel or face to face, keep the minimum separation distance specified below to avoid mutual interference.

| Model No. | C (mm in) | D (mm in) |

|---|---|---|

| GH-2SE | 15 0.591 | 10 0.394 |

| GH-3SE | 20 0.787 | 15 0.591 |

| GH-5SE | 25 0.984 | 20 0.787 |

| GH-8SE GH-F8SE | 40 1.575 | 26 1.024 |

Sensing range

- The sensing range is specified for the standard sensing object. With a non-ferrous metal, the sensing range is obtained by multiplying with the correction coefficient specified below. Further, the sensing range also changes if the sensing object is smaller than the standard sensing object or if the sensing object is plated.

Correction coefficient

| GH-2SE | GH-3SE | GH-5SE | GH-8SE GH-F8SE | |

|---|---|---|---|---|

| Iron | 1 | 1 | 1 | 1 |

| Stainless steel (SUS304) | 0.68 approx. | 0.55 approx. | 0.69 approx. | 0.64 approx. |

| Brass | 0.53 approx. | 0.35 approx. | 0.41 approx. | 0.37 approx. |

| Aluminum | 0.51 approx. | 0.33 approx. | 0.39 approx. | 0.32 approx. |

Others

- This product has been developed / produced for industrial use only.

- This product is suitable for indoor use only.

- Do not use during the initial transient time (0.5 sec.) after the power supply is switched on.

- Do not use the sensor at places having intense vibrations, as this can cause malfunction.

- Make sure that stress by forcible bend or pulling is not applied directly to the cable joint of the sensor head.