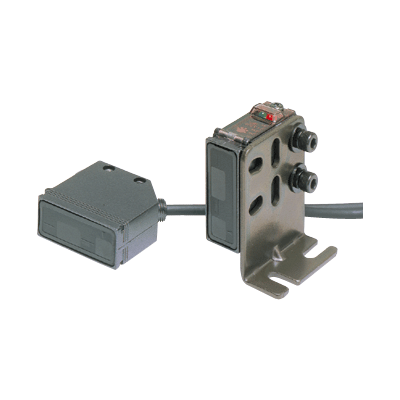

Adjustable Range Reflective Photoelectric Sensor RX-LS200 (Discontinued Products)

Download

-

Discontinued Products

-

Specifications

-

Dimensions

-

Circuit/ Wiring

-

Sensing characteristics

-

Cautions For Use

Ⅾiscontinued

Last time buy (JST)

September 30, 2022

Please refer to the details of the discontinued products and the recommended substitutes list below.

Discontinued Products

Specifications

| Type | Adjustable range reflective | ||

|---|---|---|---|

| NPN output type | PNP output type | ||

| Model No. | RX-LS200 | RX-LS200-P | |

| CE marking directive compliance | EMC Directive, RoHS Directive | ||

| Sensing range | 50 to 200 mm 1.969 to 7.874 in with white non-glossy paper (50 x 50 mm 1.969 x 1.969 in) | ||

| Hysteresis | 10 % or less of operation distance with white non-glossy paper (50 x 50 mm 1.969 x 1.969 in) | ||

| Repeatability | Along sensing axis: 1 mm 0.039 in or less, Perpendicular to sensing axis: 0.5 mm 0.020 in or less | ||

| Supply voltage | 12 to 24 V DC ±10 % Ripple P-P 10 % or less | ||

| Current consumption | 40 mA or less | ||

| Output | NPN open-collector transistor • Maximum sink current: 100 mA • Applied voltage: 30 V DC or less (between output and 0 V) • Residual voltage: 1.5 V or less (at 100 mA sink current) 0.4 V or less (at 16 mA sink current) | PNP open-collector transistor • Maximum source current: 100 mA • Applied voltage: 30 V DC or less (between output and +V) • Residual voltage: 1 V or less (at 100 mA source current) 0.4 V or less (at 16 mA source current) | |

| Utilization category | DC-12 or DC-13 | ||

| Output operation | Switchable either Light-ON or Dark-ON | ||

| Short-circuit protection | Incorporated | - | |

| Response time | 1 ms or less | ||

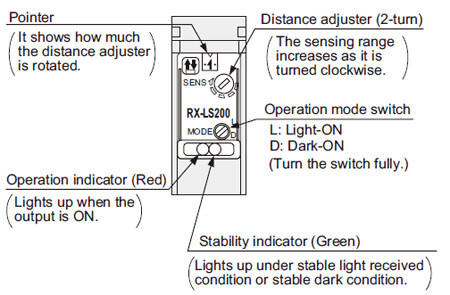

| Operation indicator | Red LED (lights up when the output is ON) | ||

| Stability indicator | Green LED (lights up under stable light received condition or stable dark condition) | ||

| Distance adjuster | 2-turn mechanical adjuster | ||

| Pollution degree | 3 (Industrial environment) | ||

| Protection | IP67 (IEC) | ||

| Ambient temperature | –25 to 60 ℃ –13 to 140 ℉ (No dew condensation or icing allowed), Storage: –30 to 70 ℃ –22 to 158 ℉ | ||

| Ambient humidity | 35 to 85 % RH, Storage: 35 to 85 % RH | ||

| Ambient illuminance | Incandescent light: 3,500 lx or less at the light-receiving face | ||

| Voltage withstandability | 1,000 V AC for one min. between all supply terminals connected together and enclosure | ||

| Insulation resistance | 20 MΩ, or more, with 250 V DC megger between all supply terminals connected together and enclosure | ||

| Vibration resistance | 10 to 500 Hz frequency, 1.5 mm 0.059 in double amplitude (10 G max.) in X, Y and Z directions for two hours each | ||

| Shock resistance | 500 m/s2 acceleration (50 G approx.) in X, Y and Z directions three times each | ||

| Emitting element | Infrared LED (peak emission wavelength: 880 nm 0.035mil, modulated) | ||

| Material | Enclosure: Die-cast zinc alloy, Indicator cover: Polyethersulphone, Lens: Polycarbonate | ||

| Cable | 0.15 mm2 3-core oil, heat and cold resistant cabtyre cable, 3 m 9.843 ft long | ||

| Cable extension | Extension up to total 100 m 328.084 ft is possible with 0.3 mm2, or more, cable. | ||

| Weight | Net weight: 85 g approx. | ||

| Accessories | MS-RX-1 (Sensor mounting bracket): 1 set, Adjusting screwdriver: 1 pc. | ||

Note:Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +23 ℃ +73.4 ℉.

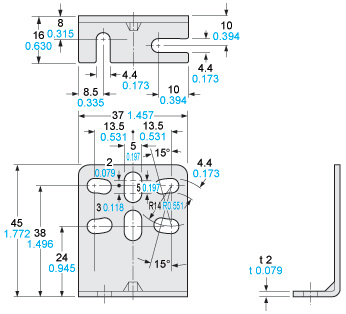

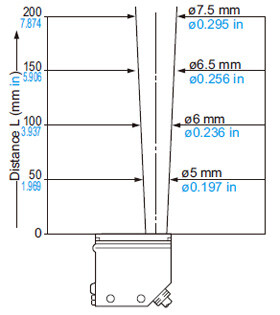

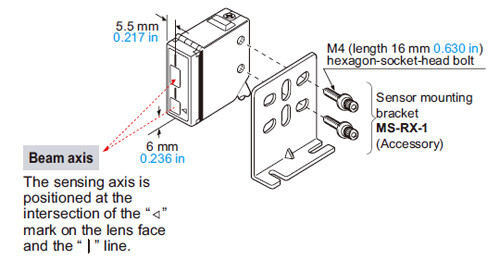

Dimensions

- Unit: mm in

RX-LS200 RX-LS200-P

Sensor

PT-RX500 PT-RX1000

Protective tube (Optional)

MS-RX-1

Sensor mounting bracket (Accessory)

Material:Cold rolled carbon steel (SPCC)Two M4 (length 16 mm0.630 in) hexagon-socket-head bolts are attached.

Assembly dimensions

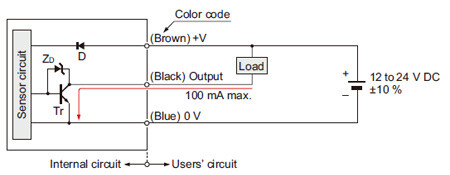

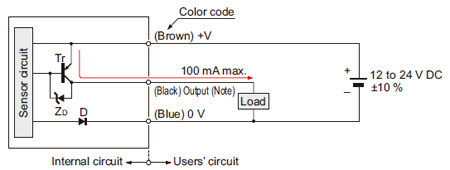

I/O Circuit and Wiring diagrams

NPN output type

RX-LS200

I/O circuit diagram

Symbols・・・D :Reverse supply polarity protection diodeZD:Surge absorption zener diodeTr:NPN output transistor

Wiring diagram

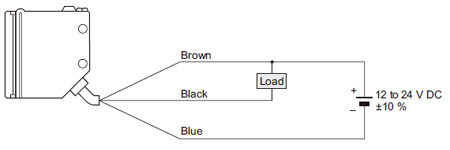

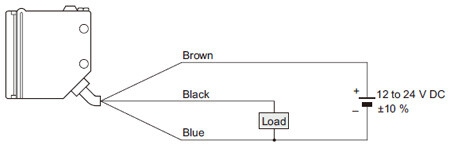

PNP output type

RX-LS200-P

I/O circuit diagram

Note:The output does not incorporate a short-circuit protection circuit.Do not connect it directly to a power supply or a capacitive load.

Symbols・・・

D :Reverse supply polarity protection diode

ZD:Surge absorption zener diode

Tr:PNP output transistor

Wiring diagram

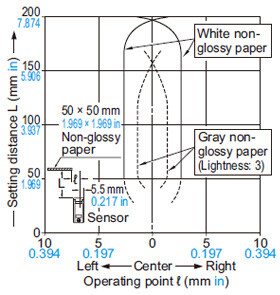

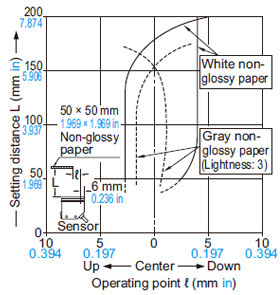

Sensing characteristics

*TYPICAL

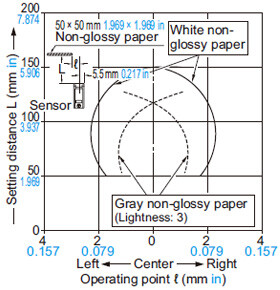

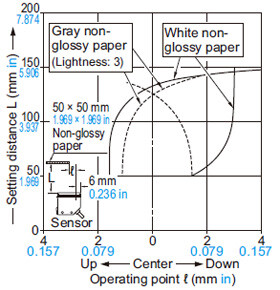

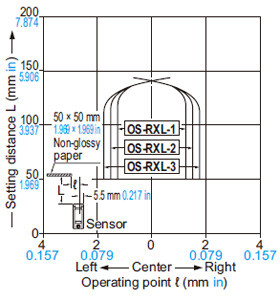

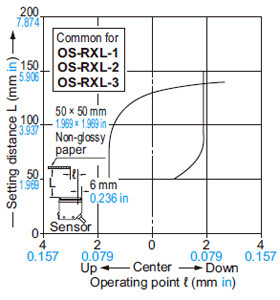

Sensing fields

・Setting distance: 200 mm

7.874 in (Horizontal)

・Setting distance: 200 mm

7.874 in (Vertical)

・Setting distance: 150 mm

5.906 in (Horizontal)

・Setting distance: 150 mm

5.906 in (Vertical)

・Setting distance: 150 mm

5.906 in with slit mask (Horizontal)

・Setting distance: 150 mm

5.906 in with slit mask (Vertical)

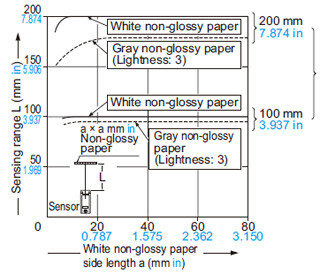

Correlation between sensing object size and sensing range

These curves show the characteristics with the maximum sensing range set to 100 mm 3.937 in, 200 mm 7.874 in, each, with white non-glossy paper (50 × 50 mm 1.969 × 1.969 in).

Emitted beam

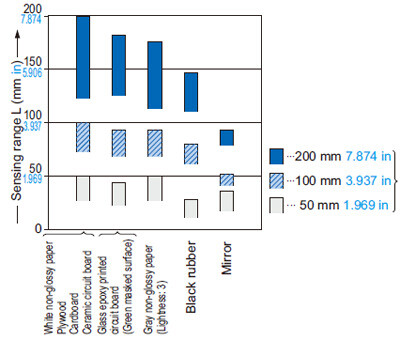

Correlation between material (50 × 50 mm 1.969 × 1.969 in) and sensing range

These bars indicate the sensing range with respective objects when the distance adjuster is set at the sensing range of 200 mm 7.874 in, 100 mm 3.937 in and 50 mm 1.969 in long, each, with white non-glossy paper.

Cautions For Use

- Never use this product as a sensing device for personnel protection.

- In case of using sensing devices for personnel protection, use products which meet laws and standards, such as OSHA, ANSI or IEC etc., for personnel protection applicable in each region or country.

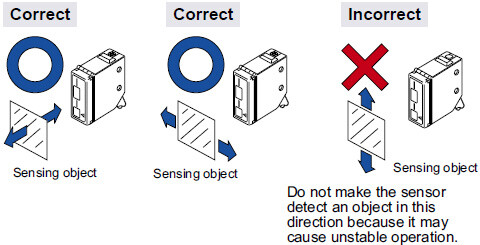

Mounting

- The tightening torque should be 1.17 N·m or less.

- Care must be taken regarding the sensor mounting direction with respect to the object’s direction of movement.

- When detecting a specular object (aluminum or copper foil) or an object having a glossy surface or coating, please take care that there are cases when the object may not be detected due to a small change in angle, wrinkles on the object surface, etc.

- When a specular body is present below the sensor, use the sensor by tilting it slightly upwards to avoid wrong operation.

- If a specular body is present in the background, wrong operation may be caused due to a small change in the angle of the background body. In that case, install the sensor at an inclination and confirm the operation with the actual sensing object.

- Do not install the sensor at a distance of less than 50 mm 1.969 in from the object because the sensing is unstable in this range.

Wiring

- The output of RX-LS200-P does not incorporate a shortcircuit protection circuit. Do not connect it directly to a power supply or a capacitive load.

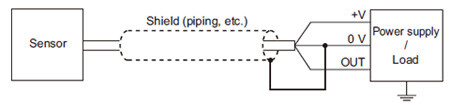

Use conditions to comply with CE Marking

- Following work must be done in case of using this product as a CE marking (European standard EMC Directive) conforming product.

Ensure that the shield is connected to 0 V or the actual ground.

・In case of connecting a sensor to power supply 0 V by using a shield (piping, etc.)

Note: The shield (piping, etc.) must be insulated.

・In case of grounding by using a shield (piping, etc.)

Others

- Do not use during the initial transient time (50 ms) after the power supply is switched on.

Distance adjustment

Adjusters

Adjusting procedure

<When a sensing object moves horizontally to the sensor>

| Step | Description | Distance adjuster |

|---|---|---|

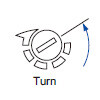

| [1] | Turn the distance adjuster fully counterclockwise to the minimum sensing range position (50 mm 1.969 in approx.). (Do not turn excessively.) |

|

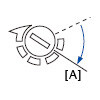

| [2] | Place an object at the required distance from the sensor, turn the distance adjuster gradually clockwise, and find out point " [A] " where the sensor changes to the light received condition. |

|

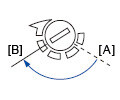

| [3] | Remove the object, turn the distance adjuster further clockwise, and find out point " [B] " where the sensor changes to the light received condition again with only the background. (When the sensor does not go to the light received condition even if the adjuster is fully turned clockwise, point " [B] " is this extreme point.) |

|

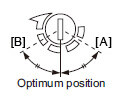

| [4] | The optimum position to stably detect objects is the center point between " [A] " and " [B] ". |

|

<When a sensing object is approaching / moving away from the sensor>

- Follow only steps [1] and [2] respectively. Since the sensing point may change depending on the sensing object, be sure to check the operation with the actual sensing object.