LED Type Wafer Alignment Sensor Controller HD-T1

Download

-

Basic Information

-

Applications

-

Order guide

-

Specifications

-

Dimensions

-

Circuit/ Wiring

-

Cautions For Use

Basic Information

The use of a safe LED light beam now allows for high precision detection with a resolution of 30 μm 1.181 mil

Contact Us

Features

No safety measures are required at all

As a safe red LED is used as the light source, there is no need for time-consuming safety measures. The protective covers usually required when using laser beams are not needed, and FDA approval is not required in order to use this sensor in the US.

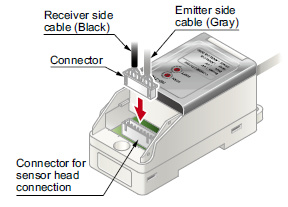

Easy installation

This unit is equipped with a one-touch connector to connect the sensor head to the controller. The amount of wiring is therefore minimized, resulting in easy maintenance.

Low current consumption of 70 mA or less

The HD-T1 series has a maximum current consumption of only 70 mA, for both the sensor head and the controller. The current consumption is almost as low as that of photoelectric sensors.

High resolution of 30 μm 1.181 mil

Although the HD-T1 series uses a red LED for its light source, it has the same high level of performance as laser sensors, thus enabling high precision detection.

No need for beam axis alignment

As both the receiver and the emitter are integrated into a single unit, there is no need to perform any troublesome alignment of the beam axis. In addition, as the HD-T1 series can perform its detection function over a broad area - with both a sensing range and a sensing width of 30 mm 1.181 in, this unit can be utilized for sensing wafers of many different sizes.

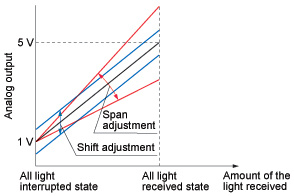

Adjustment functions for both span and shift have been incorporated

In addition to the span adjustment function, a convenient shift adjustment function has also been incorporated into the analog output (1 to 5 V). The shift adjustment function allows the analog voltage to be shifted by up to ±0.5 V.

Applications

Detecting wafer eccentricities or notches

Order guide

Sensor head

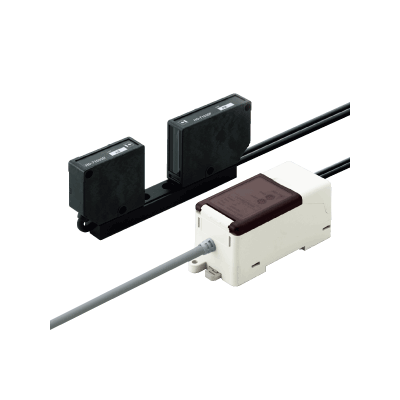

| Appearance | Sensing range | Sensing width | Model No. |

|---|---|---|---|

| 30 mm 1.181 in (fixed) (Note) | 30 mm 1.181 in | HD-T1030 |

Note :

The value is in a state that the sensor is mounted on the mounting base at the time of factory shipment.

Controller

Make sure to use the sensor head and the controller together as a set.

| Appearance | Model No. | Output |

|---|---|---|

| HD-T1C | Analog voltage ・Output voltage: 1 to 5 V |

Specifications

Sensor head

| Model No. | HD-T1030 | |

|---|---|---|

| Applicable controller | HD-T1C | |

| Sensing width | 30 mm 1.181 in (Linearity is specified at 28 mm 1.102 in width.) | |

| Sensing range | 30 mm 1.181 in (fixed) (Note 2) | |

| Pollution degree | 3 (Industrial environment) | |

| Protection | IP40 (IEC) | |

| Ambient temperature | 0 to +40 ℃ +32 to +104 ℉, Storage: -20 to +55 ℃ -4 to +131 ℉ | |

| Ambient humidity | 35 to 85 % RH (No dew condensation) | |

| Ambient illuminance | Incandescent light: 3,000 lx or less at the light-receiving face, Fluorescent light: 3,000 lx or less at the light-receiving face | |

| Voltage withstandability | 1,000 V AC for one min. between all supply terminals connected together and enclosure | |

| Insulation resistance | 20 MΩ, or more, with 250 V DC megger between all supply terminals connected together and enclosure | |

| Vibration resistance | 10 to 150 Hz frequency, 0.75 mm 0.030 in double amplitude or maximum acceleration 49 m/s2, in X, Y and Z directions for two hours each | |

| Shock resistance | 490 m/s2 acceleration (50 G approx.) in X, Y and Z directions three times each | |

| Emitting element | Red LED (Peak emission wavelength: 650 nm 0.026 mil) | |

| Receiving element | Photodiode | |

| Material | Enclosure: PEI and Aluminum, Front cover: Glass, Mounting base: Aluminum | |

| Cable | PVC cable, 0.5 m 1.640 ft long, with a connector at the end | |

| Weight | Net weight: 150 g approx. | |

Note 1:Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +20 ℃ +68 ℉.

Note 2:The value is in a state that the sensor is mounted on the mounting base at the time of factory shipment.

Controller

| Model No. | HD-T1C | |

|---|---|---|

| Applicable sensor head | HD-T1030 | |

| Supply voltage | 24 V DC ± 10 % Ripple P-P 10 % or less | |

| Current consumption | 70 mA or less (Including sensor head) | |

| Analog output | Analog voltage - Output voltage: 1 ± 0.5 V (all light interrupted) to 5 ± 0.5 V (all light received) - Output impedance: 75 Ω | |

| Response time | 0.5 ms or less (8 V/ms or more) | |

| Resolution | 30 μm 1.181 mil (Note 2) | |

| Linearity | ±1.0 % F.S. (at 28 mm 1.102 in sensing width of the sensing center) (Note 3) | |

| Temperature characteristics | ±0.1 % F.S./℃ (at 24 ± 2 ℃ 75.2 ± 35.6 ℉) (Note 3) | |

| Span adjustment function | Span of the analog output voltage is adjusted. 15-turn endless adjuster | |

| Shift adjustment function | Offset of the analog output voltage is adjusted. 15-turn endless adjuster | |

| Warming-up period | 30 min. or more | |

| Environmental resistance | Pollution degree | 3 (Industrial environment) |

| Protection | IP40 (IEC) | |

| Ambient temperature | 0 to +40 ℃ +32 to +104 ℉, Storage: -20 to +70 ℃ -4 to +158 ℉ | |

| Ambient humidity | 35 to 85 % RH (No dew condensation) | |

| Voltage withstandability | 1,000 V AC for one min. between all supply terminals connected together and enclosure | |

| Insulation resistance | 20 MΩ, or more, with 250 V DC megger between all supply terminals connected together and enclosure | |

| Vibration resistance | 10 to 150 Hz frequency, 0.75 mm 0.030 in double amplitude or maximum acceleration 49 m/s2, in X, Y and Z directions for two hours each | |

| Shock resistance | 490 m/s2 acceleration (50 G approx.) in X, Y and Z directions three times each | |

| Material | Enclosure: Heat-resistant ABS, Connector cover: Heat-resistant ABS, Adjuster cover: Polycarbonate | |

| Cable | 0.22 mm2 3-core heat-resistant PVC cable, 0.3 m 0.984 ft long | |

| Cable extension | Extension up to total 3 m 9.843 ft is possible with 0.3 mm2, or more, heat-resistant PVC cable. | |

| Weight | Net weight: 85 g approx. | |

Note 1:Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +20 ℃ +68 ℉.

Note 2:Resolution refers to the peak to peak distance conversion value of analog output (in the frequency band below 20 MHz).

Note 3:This is the representative example of measurement with a combination of sensor head and controller.

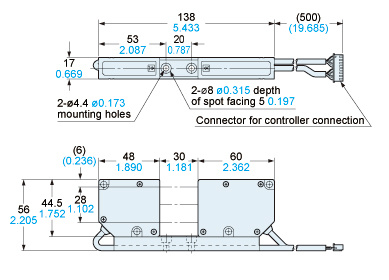

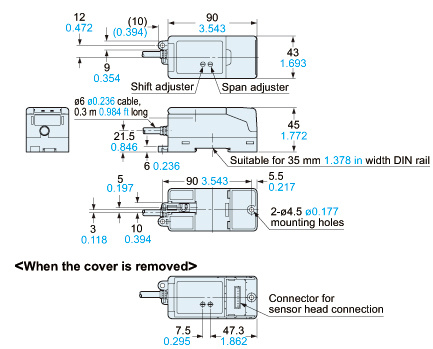

Dimensions

- Unit: mm in

HD-T1030

Sensor head

HD-T1C

Controller

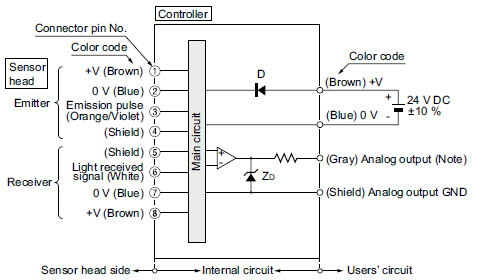

I/O Circuit and Wiring diagrams

I/O circuit diagram

Note:Analog output does not incorporate a short-circuit protection circuit.Do not connect it directly to a power supply or a capacity load.

Symbols・・・

D:Reverse supply polarity protection diode

ZD:Surge absorption zener diode

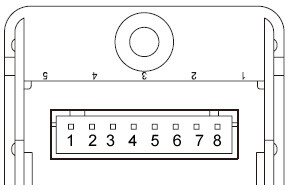

Terminal arrangement

| Terminal No. | Description | |

|---|---|---|

| 1 | +V | Emitter side |

| 2 | 0V | |

| 3 | Emission pulse | |

| 4 | Shield | |

| 5 | Shield | Receiver side |

| 6 | Light received signal | |

| 7 | 0V | |

| 8 | +V | |

Cautions For Use

- Never use this product as a sensing device for personnel protection.

- In case of using sensing devices for personnel protection, use products which meet laws and standards, such as OSHA, ANSI or IEC etc., for personnel protection applicable in each region or country.

・Make sure to use the sensor head and the controller together as a set.

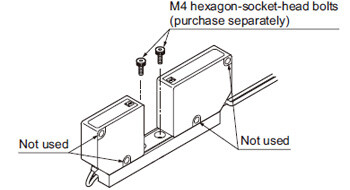

Mounting

- Mount the sensor head using 2 pcs. M4 hexagon-sockethead bolts (purchase separately) with a tightening torque of 0.5 N·m or less.

- Do not remove the screws fixing the emitter / receiver and the mounting base. If removed, the output value will change.

- Do not fix with the screws, using the mounting hole on the side of emitter / receiver.

Controller

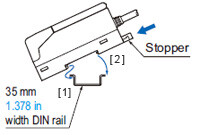

<In case of using DIN rail>

[1]Fit the front part of the mounting section of the unit on the 35 mm 1.378 in width DIN rail, pressing the stopper towards the arrow (the stopper is locked) shown in the right figure.

[2]Press down the rear part of the mounting section of the unit on the 35 mm 1.378 in width DIN rail to fit it.

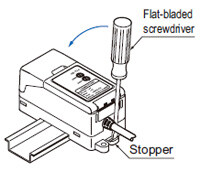

* For removal, insert a flat-bladed screwdriver into the groove of the stopper and pull the handle backwards.

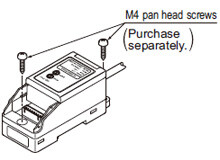

<In case of using screws>

- Mount using M4 pan head screws with a tightening torque of 1.2 N·m or less.

Wiring

- Analog output of controller does not incorporate a shortcircuit protection circuit. Do not connect it directly to a power supply or a capacity load.

- Care should be taken that static electricity is not applied to the connector during wiring. It may damage the product.

- Take care that wrong wiring will damage the product.

- Cable extension is possible up to total 3 m 9.843 ft with 0.3 mm2, or more, cable. Note that the cable length of the sensor head cannot be changed.

- Do not apply stress such as forced bending and pulling to the cable joint.

- Make sure to use an isolation transformer for the DC power supply. If an autotransformer (single winding transformer) is used, this product or the power supply may get damaged.

- In case a surge is generated in the used power supply, connect a surge absorber to the supply and absorb the surge.

Others

- This product has been developed / produced for industrial use only.

- This product is suitable for indoor use only.

- Do not use during the initial transient time (0.5 sec. approx.) after the power supply is switched on.

- This product outputs according to the amount of LED light received. Optical power varies between the center and the periphery of sensing range, and note that dimensional accuracy cannot be assured.

- Do not allow any water, oil, fingerprints, etc., which may refract light, or dust, dirt, etc., which may block light, to stick to the emitting / receiving surfaces of the sensor head. In case they are present, wipe them with a clean, dust-free soft cloth or lens paper.

- If the sensing object is specular or transparent object, note that accurate measurement may not be possible.