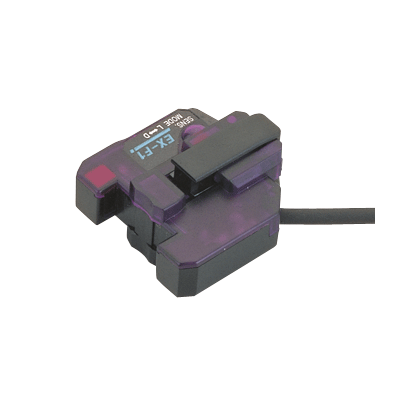

Pipe-mountable Liquid Level Detection Sensor EX-F1

Download

-

Basic Information

-

Applications

-

Order guide

-

Specifications

-

Dimensions

-

Circuit/ Wiring

-

Cautions For Use

Basic Information

Reliable liquid level detection with amplifier built-in low-priced sensor

CE : EMC Directive

UKCA : EMC Regulations

Contact Us

Features

Space-saving amplifier built-in type

EX-F1 amplifier built-in sensor saves space as there is no need to install a separate amplifier.

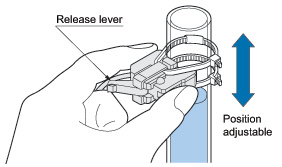

Easily mountable and adjustable

Just attach it on a pipe with the tying bands. The position can be easily changed with the release lever even after mounting, so that there is no need to cut the tying bands.

Low price

EX-F1 is very cost-effective.

Easy to check operation Indicator

The operation can be checked at a glance from different directions.

Operation mode switch

Either Light-ON or Dark-ON can be selected by a switch. This is useful to check the operation during installation because it forces the output to be turned ON or OFF even without the liquid being inside the pipe.

Applications

Detecting liquid level in a tank

Order guide

| Type | Appearance | Sensing object | Applicable pipe diameter | Model No. | |

|---|---|---|---|---|---|

| Amplifier built-in pipe-mountable |

| Liquid (Note 1) | Outer dia. ø6 to ø13 mm ø0.236 to ø0.512 in transparent pipe [PFA (Fluorine resin) or equivalently transparent pipe, wall thickness 1 mm 0.039 in (Note 2)] | EX-F1 | |

| 5 m 16.404 ft cable length type | EX-F1-C5 | ||||

Note 1:Unclear or highly viscous liquid may not be detected stably.

Note 2:Do not use the sensor with pipes other than the above specified.

Specifications

| Type | Amplifier built-in, Pipe-mountable | |

|---|---|---|

| Model No. | EX-F1 | |

| CE marking directive compliance | EMC Directive, RoHS Directive | |

| Sensing object | Liquid (Note 2) | |

| Applicable pipe diameter | Outer dia. ø6 to ø13 mm ø0.236 to ø0.512 in transparent resin pipe [PFA (Fluorine resin) or equivalently transparent pipe, wall thickness 1 mm 0.039 in ] (Note 3) | |

| Supply voltage / Current consumption | 12 to 24 V DC ± 10 % Ripple P-P 10 % or less / 30 mA or less | |

| Output | NPN open-collector transistor - Maximum sink current: 100 mA - Applied voltage: 30 V DC or less (between output and 0 V) - Residual voltage: 1 V or less (at 100 mA sink current) 0.4 V or less (at 16 mA sink current) | |

| Utilization category | DC-12 or DC-13 | |

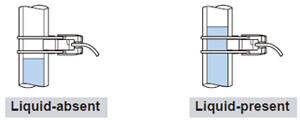

| Output operation | Switchable either Light-ON (Liquid-absent-ON) or Dark-ON (Liquid-present-ON) | |

| Short-circuit protection | Incorporated | |

| Response time | 2 ms or less | |

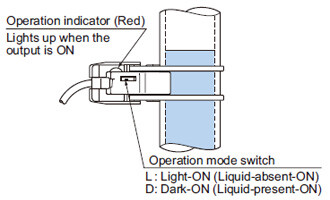

| Operation indicator | Red LED (lights up when the output is ON) | |

| Pollution degree | 3 (Industrial environment) | |

| Ambient temperature (Note 4) | -10 to +55 ℃ +14 to +131 ℉ (No dew condensation or icing allowed), Storage: -20 to +70 ℃ -4 to +158 ℉ | |

| Ambient humidity / Ambient illuminance | 35 to 85 % RH, Storage: 35 to 85 % RH / lncandescent light: 3,000 lx or less at the light-receiving face | |

| Voltage withstandability | 1,000 V AC for one min. between all supply terminals connected together and enclosure | |

| Insulation resistance | 20 MΩ, or more, with 250 V DC megger between all supply terminals connected together and enclosure | |

| Vibration resistance | 10 to 150 Hz frequency, 0.75 mm 0.030 in double amplitude in X, Y and Z directions for two hours each | |

| Shock resistance | 100 m/s2 acceleration (10 G approx.) in X, Y and Z directions three times each | |

| Emitting element | Infrared LED (modulated) | |

| Material | Enclosure: Polycarbonate, Tying band: Nylon, Anti-slip tube: Silicone | |

| Cable | 0.1 mm2 3-core cabtyre cable, 1 m 3.281 ft long | |

| Cable extension | Extension up to total 50 m 164.042 ft is possible with 0.3 mm2, or more, cable. | |

| Weight | Net weight: 15 g approx., Gross weight: 60 g approx. | |

| Accessories | Tying band: 2 pcs., Anti-slip tube: 2 pcs. | |

Note 1:Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +20 ℃ +68 ℉.

Note 2:Unclear or highly viscous liquid may not be detected stably.

Note 3:Do not use the sensor with pipes other than the above specified.

Note 4:Liquid being detected should also be kept within the rated ambient temperature range.

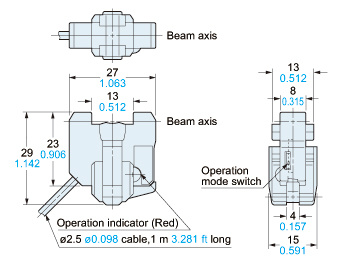

Dimensions

- Unit: mm in

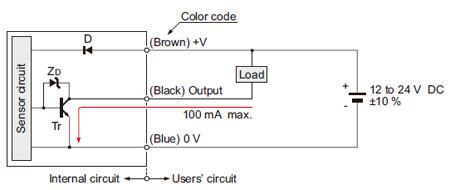

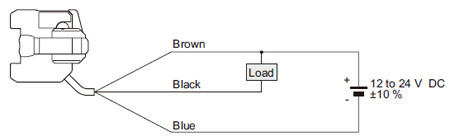

I/O Circuit and Wiring diagrams

I/O circuit diagram

Symbols・・・

D: Reverse supply polarity protection diode

ZD: Surge absorption zener diode

Tr: NPN output transistor

Wiring diagram

Cautions For Use

- Never use this product as a sensing device for personnel protection.

- In case of using sensing devices for personnel protection, use products which meet laws and standards, such as OSHA, ANSI or IEC etc., for personnel protection applicable in each region or country.

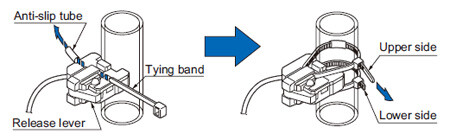

Mounting

- Mount the sensor on a pipe with the attached tying bands and anti-slip tubes as shown in the figure below. Make sure that the release lever is retracted (position as in the figure) before mounting. Fasten two tying bands, as shown, and cut off the excess portions.

- If other tying bands are to be used, the dimension A shown in the figure below should be 2.5 mm 0.098 in or less.

Selecting output operation

- Either Light-ON (Liquid-absent-ON) or Dark-ON (Liquidpresent- ON) can be selected with the operation mode switch according to your application.

- The indicator operation and the output operation are different with the setting of the operation mode switch as given in the table below.

: Lights up

: Lights up

: Lights off

: Lights off

| MODE | Sensing condition | Operation indicator | Output operation |

|---|---|---|---|

| Light-ON (Liquid-absent-ON) | Liquid-present |

| OFF |

| Liquid-absent |

| ON | |

| Dark-ON (Liquid-present-ON) | Liquid-present |

| ON |

| Liquid-absent |

| OFF |

Others

- Do not use during the initial transient time (50 ms) after the power supply is switched on.

- Do not use this sensor with a pipe which is not transparent.

- Unclear or highly viscous liquid may not be detected.

- Fit the sensor to the pipe securely, otherwise the operation may be erroneous.

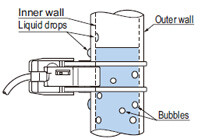

- Take care that no dew condenses on the pipe’s sensing surface or the pipe’s inside wall and that no bubble attaches on the pipe’s inside wall, since it can affect the operation. If a liquid drop flows down across the sensing point or an air bubble sticks on the wall at the sensing point, the operation may be erroneous. Make sure that no bubble arises in the liquid, and that no dew or liquid drop is present on either surface of the pipe wall.

- EX-F1 is not water-proof or chemical-resistant. Installation should be avoided at any place where it could come in direct contact with water or chemicals.