Amplifier Built-in / U-shaped Micro Photoelectric Sensor[Ultra-small / Cable type] PM-25

Download

-

Basic Information

-

Applications

-

Order guide

-

Option

-

Specifications

-

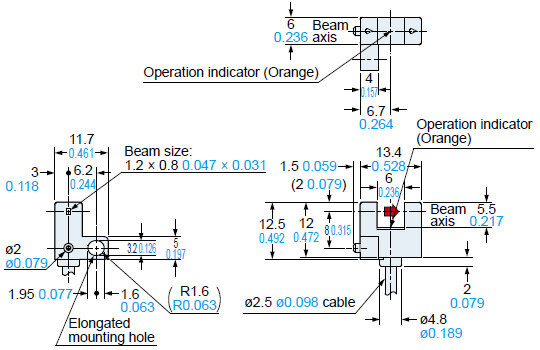

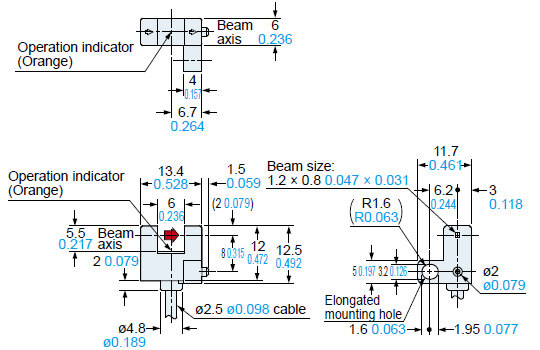

Dimensions

-

Circuit and Wiring

-

Sensing characteristics

-

Cautions For Use

Basic Information

One step ahead in performance and mounting ease

UL : Recognition

Contact Us

- Be sure to read the "Cautions For Use" when using for the above applications.

- Before using this device, be sure to confirm the standards / regulations applied in the relevant nation and region.

- If you need the Certificate or Confirmation Letter, please contact us.

Features

Sensor unit complies with ISO 13849-1*1 Category 1 PLc*2.

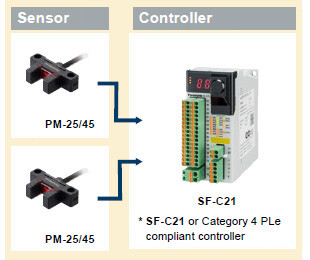

A Category 3 PLd Safety System can be built by using Category 4 PLe compliant controllers together with our sensors

*1 Safety-related parts of control systems, Part 1: General principles for design

*2 Conformed from December 2021 production.

■ Category 3, PLd construction example

[Precautions when using as Category 3 PLd]

Sensor redundancy is required!

Observe the following when connecting to the safety controller.

・In the case the product is used in a standalone state, the safety system may not operate properly when a sensor malfunction occurs.

・Do not use the two outputs from PM-25/45 series unit for achieving the redundancy (duplication) of safety circuit.

CAUTION

The product cannot be used for human body detection.

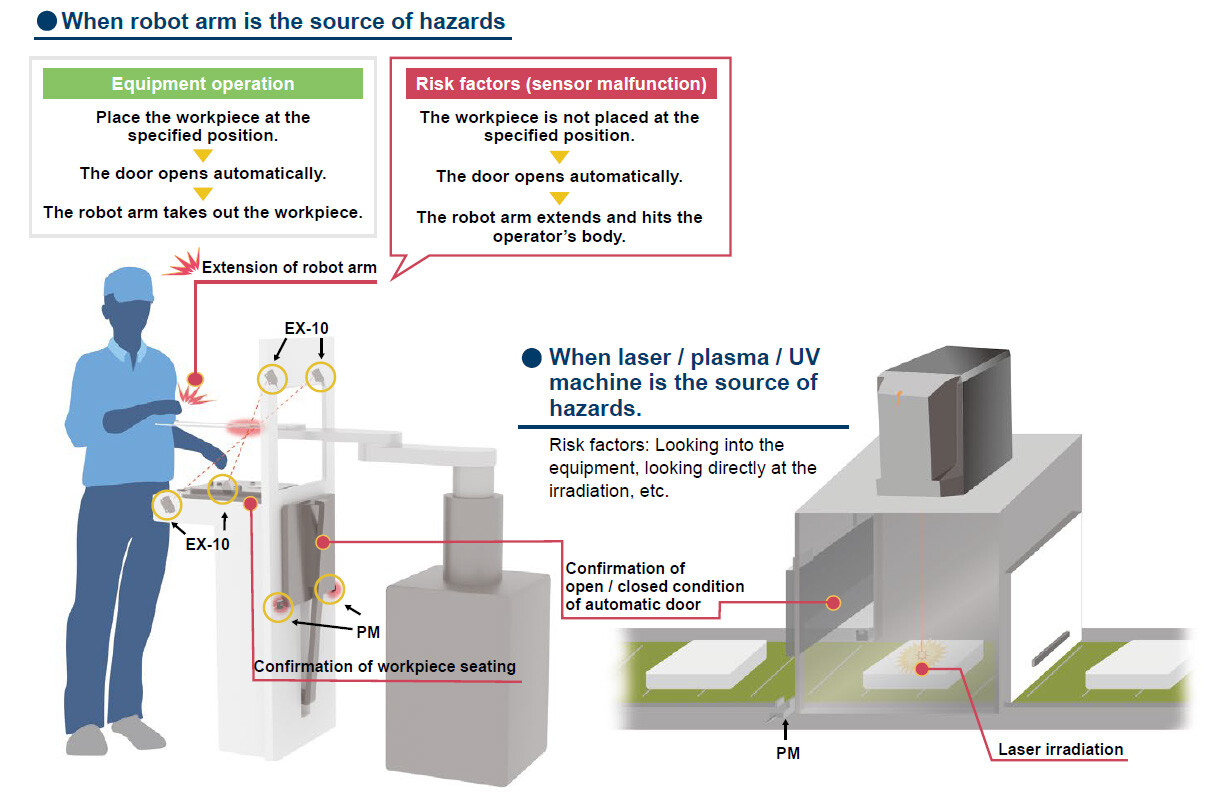

■ Application examples

[Required conditions]

1. The source of hazards is located inside the machine and may cause hazards to nearby people.

2. The equipment is classified as Category 3 PLd or lower.

3. The source of hazards is isolated only by the automatic door.

* The product can be used safely when all of the above conditions 1 through 3 are satisfied!

* There are cases where you can use it under other conditions.

* Be sure to read the "Cautions For Use" when using for safety applications.

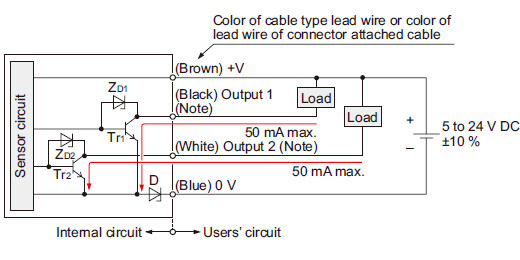

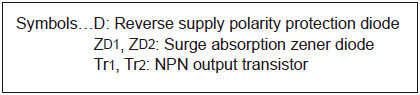

Three protection circuits standard on all models

All models are standardly equipped with the following protection circuits in their compact bodies. These protection circuits minimize the possibility of sensor malfunctions caused by erroneous wiring.

(1) Reverse supply polarity protection circuit

(2) Reverse output polarity protection circuit

(3) Output short-circuit protection circuit

Industry’s first! IP64 rating

*As of April 2017, in-company survey.

Our original integrated molding method has eliminated grooves and gaps on the sensing surface and main body, thus reducing the possibility of malfunctions caused by splashing water or dust.

Note : The above image is PM-L45.

Ample beam emitting / receiving distance of 6 mm 0.236 in

The beam emitting and receiving sections are 0.5 mm 0.02 in thinner than those on our conventional models while their external dimensions are the same. As a result, the distance between the beam emitting point and receiving point increased by 1 mm 0.039 in. The wider distance means less possibility of collision between the sensing section and sensing object.

(Unit: mmin)

Note : The above image is PM-K45.

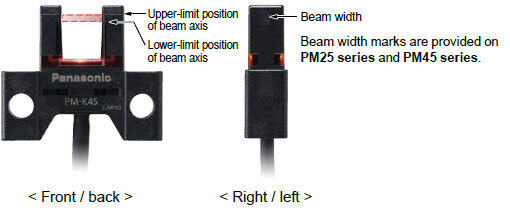

Beam marks for easy adjustment

The upper-limit and lower-limit positions of beam can be visually confirmed from the front, back, right and left sides of the sensor unit. This allows easy adjustment of the position of sensing object.

Note : The above image is PM-K45.

Large and easy to see

Multi-angle operation indicator

The large operation indicator (orange) lights up when the beam enters. The indicator is easy to see from above and from the sides.

All models easy to mount with M3 screws

The sensor unit can be installed with M2 or M3 screws.

(M2 screws, M3 screws and washers are not included.)

■Models requiring one M2 or M3 screw for installation : PM-F25, PM-R25

■Models requiring two M2 or M3 screws for installation : Models other than above

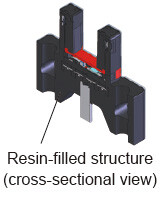

Resistant to vibrations and impacts

The sections where stress concentrates, such as the connecting section of the cable and internal circuit, are covered with a resin. This helps prevent malfunctions caused by vibrations and impacts.

Applications

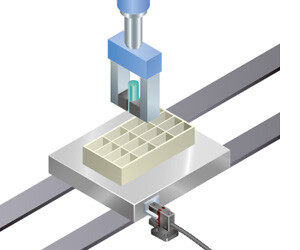

Positioning of a pallet

Pallet is stopped by sensing the dog*.

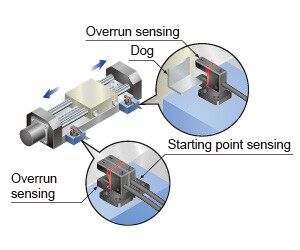

Sensing the starting point and overrun of a moving body

Starting point and overrun is sensed using the dog* on the base.

* "Dog" refers to the sensing object for activating the sensor's detecting operation.

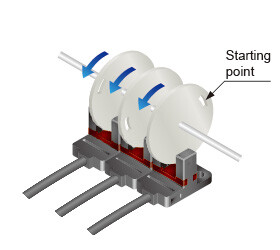

Sensing the starting point on a rotating body

The starting point can be sensed by making a slit in the rotating body.

Order guide

Ultra-small / Cable type

ISO 13849 -1 Category 1, PLc compliant model no. list (Note 1)

| Type | Appearance (mm in) | Sensing range | Model No. (Note 2) | Cable length | Output | Output operation |

|---|---|---|---|---|---|---|

| K type |

| 6 mm 0.236 in (fixed) | PM-K25 | 1m 3.281 ft | NPN open-collector transistor | Incorporated with 2 outputs: Light-ON / Dark-ON |

| PM-K25-R | 1m 3.281 ft, bending-resistant cable | |||||

| PM-K25-C3 | 3 m 9.843 ft | |||||

| PM-K25-P | 1m 3.281 ft | PNP open-collector transistor | ||||

| L type |

| PM-L25 | 1m 3.281 ft | NPN open-collector transistor | ||

| PM-L25-R | 1m 3.281 ft, bending-resistant cable | |||||

| PM-L25-C3 | 3 m 9.843 ft | |||||

| PM-L25-P | 1m 3.281 ft | PNP open-collector transistor | ||||

| U type |

| PM-U25 | 1m 3.281 ft | NPN open-collector transistor | ||

| PM-U25-R | 1m 3.281 ft, bending-resistant cable | |||||

| PM-U25-C3 | 3 m 9.843 ft | |||||

| PM-U25-P | 1m 3.281 ft | PNP open-collector transistor | ||||

| F type |

| PM-F25 | 1m 3.281 ft | NPN open-collector transistor | ||

| PM-F25-R | 1m 3.281 ft, bending-resistant cable | |||||

| PM-F25-C3 | 3 m 9.843 ft | |||||

| PM-F25-P | 1m 3.281 ft | PNP open-collector transistor | ||||

| R type |

| PM-R25 | 1m 3.281 ft | NPN open-collector transistor | ||

| PM-R25-R | 1m 3.281 ft, bending-resistant cable | |||||

| PM-R25-C3 | 3 m 9.843 ft | |||||

| PM-R25-P | 1m 3.281 ft | PNP open-collector transistor |

Notes :

1) Conformed from December 2021 production. When ordering a product that complies with safety standards, please order Lot No. "1L1" (First 3 digits) or later.

2) The suffix "-R" in the model No. indicates a bending-resistant cable type. The suffix "-C3" indicates a 3 m 9.843 ft cable length type.

Option

| Designation | Model No. | Description |

|---|---|---|

| Mounting screw | MS-M2 | Mounting screw with washers for the ultra-small type sensor (50 pcs. lot). It can mount securely as it is spring washer attached. |

MS-M2

M2 (length 10 mm0.394 in)screw with a spring washer

Recommended e-CON connector

Manufactured by 3M Japan Limited

Adapted connector : 37104-4080-G00 FL

Please refer to "Introducing the 3M™ mini-clamp connector" for details.

Specifications

| Type | Ultra-small / Cable type | |||

|---|---|---|---|---|

| Bending-resistant cable | 3 m 9.843 ft cable | |||

| Model No. | NPN output | PM-□25 | PM-□25-R | PM-□25-C3 |

| PNP output | PM-□25-P | - | - | |

| Applicable regulations and certifications | CE Marking (EMC Directive, RoHS Directive), UKCA Marking (EMC Regulations, RoHS Regulations), ISO 13849-1 (Category 1, PLc) (Note 2), UL/c-UL Recognition certification | |||

| Sensing range | 6 mm 0.236 in (fixed) | |||

| Minimum sensing object | 0.8 × 1.2 mm 0.031 × 0.047 in opaque object | |||

| Hysteresis | 0.05 mm 0.002 in or less | |||

| Repeatability | 0.01 mm 0.0004 in or less | |||

| Supply voltage | 5 to 24 V DC ±10 % Ripple P-P 10 % or less | |||

| Current consumption | 15 mA or less | |||

| Output | <NPN output type> NPN open-collector transistor ・Maximum sink current: 50 mA ・Applied voltage: 30 V DC or less (between output and 0 V) ・Residual voltage: 2 V or less (at 50 mA sink current), 1 V or less (at 16 mA sink current) <PNP output type> PNP open-collector transistor ・Maximum source current: 50 mA ・Applied voltage: 30 V DC or less (between output and + V) ・Residual voltage: 2 V or less (at 50 mA source current), 1 V or less (at 16 mA source current) | |||

| Output operation | Incorporated with 2 outputs: Light-ON / Dark-ON | |||

| Short-circuit protection | Incorporated | |||

| Response time | Under light received condition: 20 μs or less Under light interrupted condition: 80 μs or less (Maximum response frequency: 3 kHz) (Note 3) | |||

| Operation indicator | Orange LED (lights up under light received condition) | |||

| Pollution degree | 3 | |||

| Protection | IP64(IEC) | |||

| Ambient temperature (Note 4, 5) | –25 to +55 ℃ –13 to +131 ℉ (No dew condensation or icing allowed), Storage: –30 to +80 ℃ –22 to +176 ℉ | |||

| Ambient humidity | 5 to 85 % RH, Storage: 5 to 95 % RH | |||

| Ambient illuminance | Fluorescent light: 1,000 ℓx at the light-receiving face | |||

| Voltage withstandability | 1,000 V AC for one min. between all supply terminals connected together and enclosure | |||

| Insulation resistance | 20 MΩ, or more, with 250 V DC megger between all supply terminals connected together and enclosure | |||

| Vibration resistance | 10 to 2,000 Hz frequency, 1.5 mm 0.059 in double amplitude (maximum acceleration 196 m/s2) in X, Y and Z directions for two hours each | |||

| Shock resistance | 15,000 m/s2 acceleration (1,500 G approx.) in X, Y and Z directions three times each | |||

| Emitting element | Infrared LED (Peak emission wavelength: 855 nm 0.034 mil, non-modulated) | |||

| Material | Enclosure: PBT, Display section: Polycarbonate | |||

| Cable | 0.09-mm2 4-core cabtyre cable, PVC, 1 m 3.281 ft long | 0.1-mm2 4-core bending-resistant cabtyre cable, PVC, 1 m 3.281 ft long (Note 6, 7) | 0.09-mm2 4-core cabtyre cable, PVC, 3 m 9.843 ft long | |

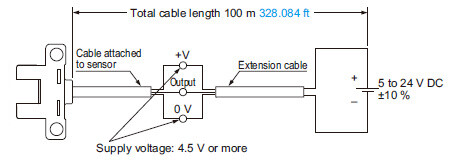

| Cable extension | Extension up to total 100 m 328.084 ft is possible with 0.3 mm2, or more, cable. (Note 8, 9) | |||

| Weight | Net weight: 10 g approx., Gross weight: 15 g approx. | Net weight: 30 g approx., Gross weight: 35 g approx. | ||

Notes:

1) Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +23 ℃ +73.4 ℉.

2) Conformed from December 2021 production.

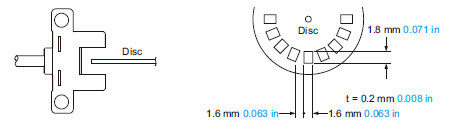

3) The response frequency is the value when the disc, given in the figure below, is rotated.

4) In case the PM-25 series is used at an ambient temperature of +50 ℃ +122 ℉, or more, make sure to mount it on a metal body.

5) Note that the cable of PM-□25-R loses its flexibility when the ambient temperature decreases to about -10 ℃ +14 ℉.

6) The cable of PM-□25-R is a bending-resistant cable usable on a moving base. When the sensor is mounted on a moving base, secure the sensor cable joint at the unit in place so that stress is not applied to it.

7) When storing PM-□25-R, make sure that the cable does not come into contact with the sensing section or operation indicator.

8) If the cable is extended to 20 m 65.617 ft or longer, confirm that the supply voltage at the end of the cable attached to the sensor is 4.5 V or higher.

9) For safety applications, do not exceed 30 m 98.425 ft.

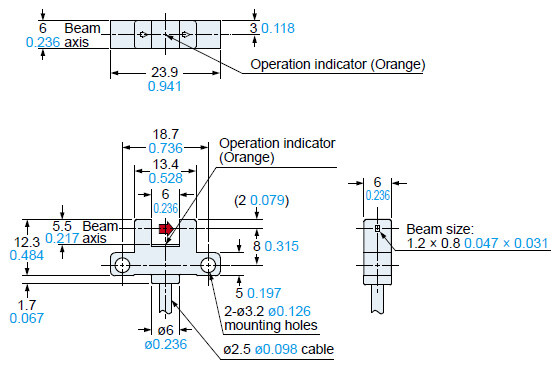

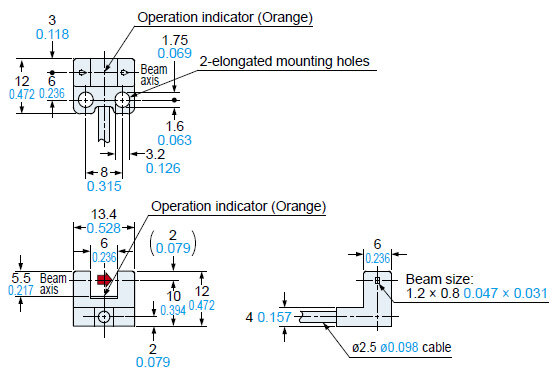

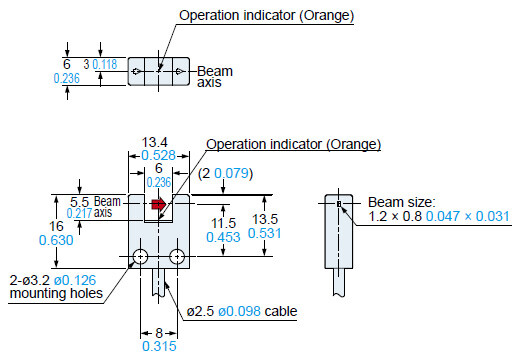

Dimensions

- Unit: mm in

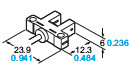

PM-K25□

Sensor

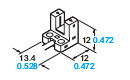

PM-L25□

Sensor

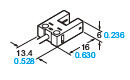

PM-U25□

Sensor

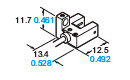

PM-F25□

Sensor

PM-R25□

Sensor

I/O Circuit and Wiring diagrams

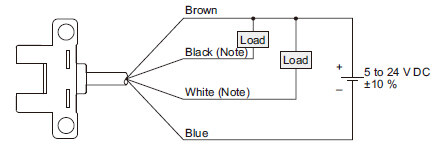

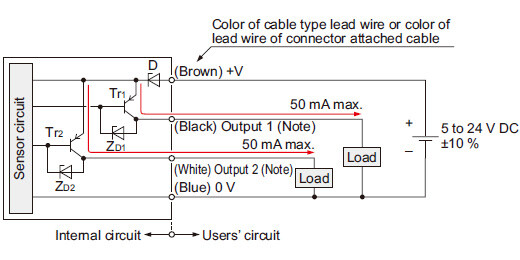

NPN output type

I/O circuit diagram

Note: Ensure to insulate the unused output wire.

Wiring diagram

Note: Ensure to insulate the unused output wire.

Output operation

| Color code | Output operation | |

|---|---|---|

| Output 1 | Black | Light-ON |

| Output 2 | White | Dark-ON |

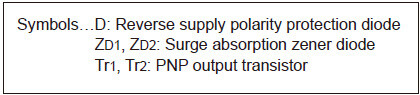

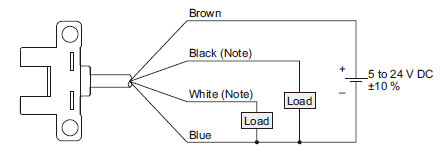

PNP output type

I/O circuit diagram

Note: Ensure to insulate the unused output wire.

Wiring diagram

Note: Ensure to insulate the unused output wire.

Output operation

| Color code | Output operation | |

|---|---|---|

| Output 1 | Black | Light-ON |

| Output 2 | White | Dark-ON |

Sensing characteristics

TYPICAL

Sensing position

Cautions For Use

- Do not use this product for an application where it directly detects the human body. Otherwise, there is a risk of death or serious injury.

- When the human body needs to be detected for safety application, use products that conform to the laws and standards related to human body detection for safety application in each country, such as OSHA, ANSI, and IEC.

- The PM-□25 conforms to the international standard ISO 13849-1 (Category 1, PLc) and can be used as a detection device to indirectly protect the human body.

- When using the PM-□25 as a part of the safety system, observe the precautions summarized in the “When Using for Safety Applications”. The “When Using for Safety Applications” explains important rules that must be observed to prevent personal injury and property damage when using the product as a part of the safety system. The “When Using for Safety Applications” can be downloaded from the following website.

>>Go to Data download

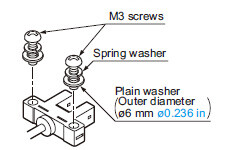

Mounting

| Screw | Spring washer | Flat washer | Tightening torque |

|---|---|---|---|

| M2 screw | 1 pc. | ø4.3 mm ø0.169 in (small round washer) | 0.15N・m |

| M3 screw | 1 pc. | ø6 mm ø0.236 in (small round washer) | 0.5N・m |

- The following conditions must be observed when using screws to mount the sensor unit.

<When using M2 screws for mounting>

<When using M3 screws for mounting>

When using the optional mounting screw set MS-M2, a spring washer is included.

- In case the PM-25 series is used at an ambient temperature of +50 ℃ +122 ℉, or more, make sure to mount it on a metal body.

Cable extension

- Cable extension is possible up to an overall length of 100 m 328.084 ft with a 0.3 mm2, or more, cable. However, since a voltage drop shall occur due to the cable extension, ensure that the power supply voltage at the end of the cable attached to the sensor is within the rating.

But, when the overall cable length, including the cable attached to the sensor, is as given below, there is no need to confirm the voltage.

| Conductor crosssection area of extension cable | Total cable length |

|---|---|

| 0.08 to 0.1mm2 | Up to 5 m 16.404 ft |

| 0.2mm2 | Up to 10 m 32.808 ft |

| 0.3mm2 | Up to 20 m 65.617 ft |

Other

- This device has been developed / produced for industrial use only.

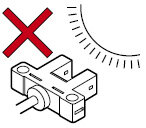

- Since the sensor is intended for use inside machines, no special countermeasures have been taken against extraneous light. Take care that extraneous light is not directly incident on the beam receiving section.

- Do not use during the initial transient time (50 ms) after the power supply is switched on.

- If the sensor is used in a place having excessive dust, periodically clean the emitting and receiving sections with a dry, soft cloth.

- If there is a large surge generating equipment, such as, motor, solenoid, electromagnetic valve, etc., in the vicinity of the sensor, use a surge absorber on that equipment. Further, do not run the sensor cables along power lines and use a capacitor between +V and 0 V, if required. Use the sensor after confirming that the surge has been eliminated.

- Note that the cable of PM-□25-R loses its flexibility when the ambient temperature decreases to about -10 ℃ +14 ℉.

- The cable of PM-□25-R is a bending-resistant cable usable on a moving base. When the sensor is mounted on a moving base, secure the sensor cable joint at the unit in place so that stress is not applied to it.

- When storing PM-□25-R, make sure that the cable does not come into contact with the sensing section or operation indicator.