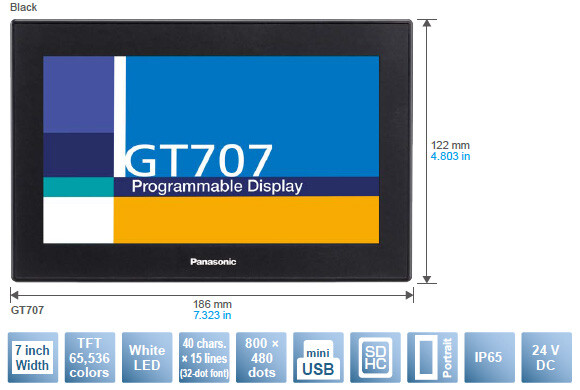

GT707

Download

-

Basic Information

-

Order guide

-

Option

-

Specifications

-

Dimensions

-

Software

-

PLC Compatibility

------------------------------ Tab1 showing ------------------------------

Basic Information

Wide screen, small body

7 inch width in space of a 5.7 inch!

Contact Us

Features

• The panel face protection sheet for the GT series is available as an option.

7 inch type can be placed in the space of a 5.7 inch type.

Since 7 inch type can fit in a 5.7 inch type space, the screen shows more and the product looks greater.

■Usable screen comparison

7 inch, 65,536 colors TFT color LCD equipped with long life LED backlight

Easy-to-view screen thanks to use of a TFT LCD with contrast ratio of 500 : 1.

Slim frame and body

Designed for easy installation with slim frame and body compared to LCD

Built-in SD / SDHC memory card slot

Easy to copy, back up, and restore screen data.

Data logging possible.

Integrated USB Interface

You can connect your PC and GT707 using your USB cable to transfer screen data. When used with our FP series PLC, this display supports the pass through function, which allows simultaneous debugging of the PLC and the display.

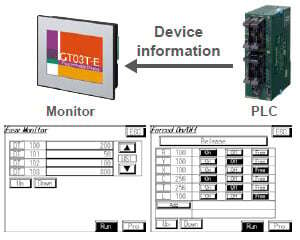

Device monitor shows PLC status without a PC

You can directly check PLC devices from the Programmable Display without having to use a PC (FPWIN GR / FPWIN GR7).

The device monitor is easily viewed from the system menu, which eliminates the bother of screen creation (except FP7).

Confirm PLC wiring and operation status simply and efficiently

Whether the PLC is installed inside the equipment where it is not visible or in a remote location you can still monitor PLC input/output status.

With simply drag and drop functionality, from PLC templates found in the parts library registered in GTWIN, you can easily verify the wiring and operation status.

Transfer programs from Programmable Display to PLC

Transfer of PLC ladder programs and Programmable Display screen data is possible from a SD / SDHC memory card without using a PC.

Also, PLC ladder programs can be backed up inside the Programmable Display and restored at any time (except FP7).

SD Solutions only Panasonic Industry can provide

Links and expansion via SD

As small-size touch panels have significantly improved their image quality, easy to read displays with sharp characters are no longer special features these days.

Instead, programmable displays will evolve with maximum "user-friendliness" in various applications with PCs or other devices.

As shown below, our touch panels exchange and store data using SD memory card, data for many applications.

PLC program transfer without the use of a PC

It is possible to modify PLC ladder programs as well as the GT screen programs by using an SD / SDHC memory card.

SD / SDHC memory card enables everyone to easily modify programs.

* Our FP series, excluding FP7 / FP0H.

SD card data transfer function

Log and other data saved on a SD memory card inserted into the GT’s onboard SD memory card slot can now be sent to a PC using a USB connection.

Notes:

1) Installation on the PC of GT_SD_Reader software is required. This software is installed simultaneously with Terminal GTWIN (Ver. 2.E1 and higher).

2) The GT unit firmware must be a version that supports this function. If you are using a version that does not support this function, please upgrade by downloading it from our website.

SD logging function to produce data “Visualization”

Capable of automatically collecting electrical power readings of Eco-POWER METERS and displaying them in a real time graph, allowing users to take quick actions for solutions.

● The GT unit can collect data, such as electrical power on an SD / SDHC memory card, and display the log data in a real time graph.

You can make data “Visualization” without using a PC as a display or Data logger for collecting data.

● One bar graph has a maximum of eight bars and can be combined with line graphs.

● The following three conditions can be selected to trigger an operation to save log data.

(1) Specified time (2) Specified cycle (1 sec. to 24 hrs.) (3) Specified condition

● Large volumes of data can be saved on an SD / SDHC memory card, which can be carried with you.

SD recipe function

For high-mix production, recipe data up to 64 types and 4,096 devices in total, can be easily set on a PC. The created recipe data is saved on an SD / SDHC memory card, and the specified data can be written or read from a PLC.

Saving alarm history data on an SD / SDHC memory card

The alarm history data stored in the GT built-in memory can be saved on an SD / SDHC memory card, making it possible to easily control problems on a PC.

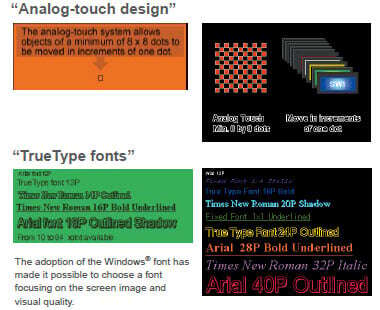

Highly flexible screen design!

GT series displays use an analog-touch panel where locations of parts and characters can be adjusted in increments of one dot. The adoption of the Windows® font has widened the character size selection (10 to 240 dots), making the screen design more flexible.

Note : The maximum size varies depending on the model.

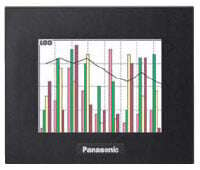

Graph function

One bar graph has a maximum of eight bars and can be combined with line graphs.

Portrait display ideal for narrow spaces

The unit can display screens in portrait orientation and can therefore be installed in narrow spaces, expanding system design possibilities and contributing to size reduction.

The portrait display is also ideal for slim equipment without enough space to install a display.

Flow display function

A flowing message of up to 64 characters (two-byte) can be displayed at the bottom of the screen. (128 messages)

Multi-function switches

Multiple operations are possible. For example, screens can be switched by setting multiple values.

4,096-color parts libraries

3D-design buttons with higher visibility and operability are available.

FP monitoring function [FP0H / FP2SH / FP0R / FP-Σ / FP-X / FP-X0 / FP-e]

*Excluding FP7

Five convenient features of GT series for improved compatibility with our FP series of PLCs

[1] Device monitor (Display and change values of FP series devices. Three different modes available.)

(1)Easy monitor mode:Use this mode when you want to monitor something. Display is continuous when one device is specified and the device can be changed.

(2)Entry monitor mode:Use this mode when you want to monitor multiple devices. You can register devices you want to display one-by-one and you can change them.

(3)Forced on / off mode:Use this mode feature to forcibly turn output on and off. You can set devices one-by-one for which you want to control output.

[2] System register monitor (Display and change of system register values.)(Excluding FP0H))

You can specify the system register number, display the value, and change it.

[3] Shared memory monitor (Display shared memory values.)

You can specify the slot number, bank number and address, and display the value. You cannot change the value.

[4] Error monitor (Display an error occurring in the FP series PLC.)

You can display the self-diagnostic result, error code and error flag, and you can even clear the error.

[5] Password setting (Set the password to protect FP series program reading and writing functions.)

Password registration and clearing is possible for the FP series password protection function.

Multiple GT displays can be connected to our PLC FP series. (RS-485 type)

GT link function

Up to 32 GT displays can be connected to one PLC unit without communication programs. The same screen operation is possible at a conveyor line or other remote locations, and the number of PLC units can be reduced, cutting the production process costs.

Notes:

1) As the number of connected units increases, the response slows down.Check the speed in the actual line.

2) The response time becomes relatively longer than those in the case of one-to-one connection. Please evaluate whether a sufficient performance can be obtained in designing the system.

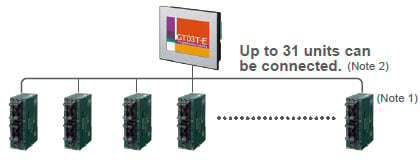

Connectivity with multiple PLCs

Up to 31 PLC units can be connected to one GT unit. Progress in multiple production lines can be centrally monitored and controlled via one GT unit.

Notes:

1) This function cannot be used for a data link between PLCs.

2) The response time becomes relatively longer than those in the case of one-to-one connection. Please evaluate whether a sufficient performance can be obtained in designing the system.

Enhanced security with password protection

Password protection and operation security functions protect the data asset in the display unit and control the authorization for operation.

Password protection function

The screen data upload operation can be restricted by using passwords to protect the data asset in the display unit.

Operation security function

Up to 64 operators can set individual passwords, and up to 16 levels of restrictions can be set on displays and operations for each part. The registered users and passwords can be changed on the display unit.

High-efficiency operation with through function

This function allows operators to simultaneously carry out the transfer of screen data of a GT series display and the debugging of our FP series PLC connected to the display.

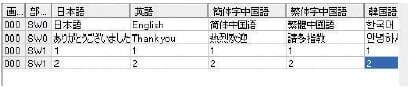

Easy-to-switch language

Conventionally, screens were created for each language. With this new language switching function, data can be registered in multiple languages (up to 16) for each part. The characters can be easily edited with Microsoft Excel® and then imported.

Write device function

This function modifies the PLC data or turns bits on/off according to the PLC status or the screen No. Now four arithmetic operations between devices are also possible.

------------------------------ Tab2 showing ------------------------------

Order guide

Main unit and tool software

GT707

| Product name | Description | Part No. | |||||

|---|---|---|---|---|---|---|---|

| LCD | Screen size | Power supply | Communication port | Color of front panel | SD memory card slot | ||

| color | TFT color LCD (white backlight) | 7 inch | 24 V DC | RS-232C | Black | Available | AIG707WCL1G2 |

| Product name | DescriptionScreen size | Part No. | |

|---|---|---|---|

| Terminal GTWIN Ver.3 *1 | Japanese version | Terminal GTWIN CD-ROM | AIGSGT7JP |

| English version | Terminal GTWIN CD-ROM | AIGSGT7EN | |

Note: The model of the "Available" have a built-in clock.

*1: Some functions are not supported in GT series other than GT703/704/707.

PLC connection cable

■24V DC

| Power supply and communication port | Connection cable | PLC |

|---|---|---|

| 24 V DC RS-232C |

PLC connection cable (3 m 9.843 ft) 9-pin D-SUB - 5-pin mini DIN (L type) | Our FP series (Excluding FP7 / FP0H / FP-XH)*1 |

*1: For FP7 / FP0H / FP-XH, please use commercially available D-SUB 9-pin (female) connector cable with a connector free wire.

------------------------------ Tab3 showing ------------------------------

Option

Panel face protection sheets

10 sheets in a set (option)

Part No. :AIG7A07S01

Spare connector

5 connectors for communication and power supply in a setPackage includes one set.

Part No. :AIGT084

Backup battery

Part No. :AFPABAT001

------------------------------ Tab4 showing ------------------------------

Specifications

| Item | GT707 | |

|---|---|---|

| 24V, RS-232C | ||

| Applicable regulations | CE Marking (EMC Directive, RoHS Directive) (Excluding some models), UKCA Marking (EMC Regulations, RoHS Regulations) (Excluding some models) | |

| Power supply | 24 V DC | |

| Operating voltage range | 21.6 to 26.4 V DC | |

| Power consumption | 6 W or less | |

| Power supply unit isolation method | Transformer isolation | |

| Ambient temperature | 0 to +50 ℃ +32 to +122 ℉ | |

| Ambient humidity | 20 to 85 % RH (at +25 ℃ +77 ℉) (No dew condensation allowed) | |

| Storage temperature | -20 to +60 ℃ -4 to +140 ℉ | |

| Storage humidity | 10 to 85% RH (at 25 ℃ +77 ℉) (No dew condensation allowed) | |

| Vibration resistance | 5 to 8.4 Hz amplitude: 3.5 mm 0.138 in, 8.4 to 150 Hz acceleration 9.8 m/s2, 10 sweeps each in X, Y and Z directions (1 octave/min.) | |

| Shock resistance | 147 m/s2, 3 times in each of the X, Y and Z directions | |

| Superposed noise suppression | 1,000 V [P-P] or more, pulse width of 50 ns, 1 μs between power supply terminals (by a noise simulator) | |

| Protection | IP65 (in the initial stages)(Note 1) | |

| Net weight | 360 g approx. | |

| Display | Display device | TFT color LCD |

| Resolution | 800 (W) × 480 (H) dots | |

| Display color | 65,536 colors | |

| Displayable area | 153.8 (W) × 85.6 (H) mm W6.055(W) × H3.370(H) in | |

| Backlight | White LED | |

| Functions | Font types | True Type (GTWIN): 10 to 240 dots, Windows®: 10 to 240 dots |

| Languages | Japanese, English, Simplified Chinese, Traditional Chinese, Korean, German, Italian, Spanish, French, Turkish, Russian, Vietnamese | |

| Graphics | Straight lines, Continuous straight lines, Squares, Circles, Arcs, Curves, Fan shapes, Polygons, Fill, Bitmaps | |

| Number of screens (Note 2) | 230 screens approx. | |

| Screen setting No. | Base screens: No. 0 to 3FF, Key board screens: No. 0 to 7, Login screens: No. 0 to F | |

| Part functions | Lamps, Switches, Data, Bar graphs, Clocks, Keyboards, Line graphs, Alarm list | |

| Other functions | Recipe, Flow display, Write device, Multi language exchange, Operation security, Data logging, SD recipe | |

| Clock function | Provided with a built-in clock. (Can also refer to and display a PLC clock.) * Buy the backup battery [AFPABAT001]. | |

| Backlight brightness adjustment | Can be set on the menu screen, via the GT configuration screen of GTWIN, or via PLC. (There are some minor variations in the backlight brightness.) | |

| Contrast adjustment | Not adjustable | |

| Buzzer | Installed | |

| Automatic communication settings | The communication speed (baud rate) is automatically changed if there is no response from the target equipment. | |

| Through function | GT connected between PC and PLC allows PLC to be debugged without a direct connection to a PC. | |

| Screen creation | Dedicated software should be used. Applicable OS: Windows® Vista / 7 / 8 / 8.1 / 10 (Note 3) | |

| Touch key resolution | Free layout (8 dots min.) | |

| Touch key operation force | 0.8 N or less | |

| Touch key life | 1 million operations or more (at +25 ℃ +77 ℉) | |

| COM. Port | Communication standard | Conforms to RS-232C |

| External communication conditions | Baud rate: 9,600 bps, 19,200 bps, 38,400 bps, 57,600 bps, 115,200 bps Data bits: 7 or 8 bits, Parity: None, Odd, Even, Stop bits: 1 bit | |

| Protocol | Our FP series supported, General-purpose serial interface supported, and Other companies' PLC supported (Refer to the compatible PLC list for manufacturers and models.) | |

| Connector | D-SUB connector (9 pins) | |

| Screen data transfer interface | Communication standard | USB2.0 |

| Protocol | Our dedicated protocol | |

| Connector | USB Mini-B | |

| User's memory | Memory | F-ROM |

| Capacity | 76 Mbyte | |

| Memory backup | Memory | SRAM |

| Backup battery | Battery less | |

Notes:

1) This protective structure condition applies to the front surface of the installed panel. This condition does not guarantee usage in all environments provided by users.

2) The number of screens that can be registered varies according to the registered contents.

3) The 64-bit version is not supported except for Windows® 7 / 8 / 8.1 / 10.

Windows is registered trademark or trademark of Microsoft Corporation in the United States and other countries.

Conformance to the UL / c-UL standards

| UL / c-UL file No. | E96300 |

|---|---|

| UL standard No. | UL508 |

------------------------------ Tab5 showing ------------------------------

Dimensions

- Unit: mm in

Applicable panel thickness : 1.0 to 5.0 mm 0.039 to 0.197 in

------------------------------ Tab6 showing ------------------------------

------------------------------ Tab7 showing ------------------------------

PLC Compatibility

Models listed are the models that have been evaluated as of November, 2016.

| Company name | Series | Model | RS-232C type | RS-422 / RS-485 type*2 |

|---|---|---|---|---|

| Our company | FP series | FP7 | ◎ | ○ |

| FP-X | ◎ | ○ | ||

| FP-X0 | ◎ | ○ | ||

| FPΣ | ◎ | ○ | ||

| FP-e | ◎ | ○ | ||

| FP0 | ◎ | ○ | ||

| FP0R | ◎ | ○ | ||

| FP2 | ◎ | ○ | ||

| FP2SH | ◎ | ○ | ||

| Mitsubishi Electric*1 | FX series | FX0N | ○ | ◎ |

| FX1S | ○ | ◎ | ||

| FX1N | ○ | ◎ | ||

| FX1NC | ○ | ◎ | ||

| FX2N | ○ | ◎ | ||

| FX2NC | ○ | ◎ | ||

| FX3UC | ○ | ◎ | ||

| FX3U | ○ | ◎ | ||

| FX3G | ○ | ◎ | ||

| FX3GC | ◎ | |||

| IQ-F series | FX5U | ○ | ◎ | |

| FX5UC | ○ | ◎ | ||

| Q series | Q00CPU | ◎ | ||

| Q01CPU | ◎ | |||

| Q00JCPU | ○ | |||

| Q00HCPU | ○ | |||

| Q00UJCPU | ◎ | |||

| Q26UDHCPU | ○ | ○ | ||

| Q25HCPU | ◎ | |||

| Q12HCPU | ◎ | |||

| Q06HCPU | ◎ | |||

| Q02HCPU | ◎ | |||

| Q02CPU | ◎ | |||

| A series (Except GT7□□) | A1N | ○ | ||

| A2N | ○ | |||

| A3N | ○ | |||

| A1S | ○ | |||

| A1SJ | ○ | |||

| A2SH | ○ | |||

| A1SH | ○ | |||

| A2CCPU24 | ◎ | |||

| Omron*1 | C series | C200H | ○ | |

| C200HS | ◎ | |||

| C500 | ○ | |||

| C500F | ○ | |||

| C1000H | ○ | |||

| C2000 | ○ | |||

| C2000H | ○ | |||

| C1000HF | ○ | |||

| C20H | ◎ | |||

| C28H | ◎ | |||

| C40H | ◎ | |||

| C120 | ○ | |||

| C120F | ○ | |||

| CQM1-CPU42 | ◎ | |||

| SRM1-C02 | ◎ | |||

| CPM2A | ◎ | |||

| CPM1-20CDR-A | ○ | |||

| CQM1H-CPU21 | ◎ | |||

| CPM2C | ◎ | |||

| CPM2B | ◎ | |||

| α series | C200HE-CPU32(-Z) | ○ | ||

| C200HG-CPU33(-Z) | ○ | |||

| C200HG-CPU53(-Z) | ○ | |||

| C200HX-CPU34(-Z) | ○ | |||

| C200HX-CPU54(-Z) | ○ | |||

| C200HE-CPU42(-Z) | ◎ | |||

| C200HG-CPU43(-Z) | ◎ | |||

| C200HG-CPU63(-Z) | ◎ | |||

| C200HX-CPU44(-Z) | ◎ | |||

| C200HX-CPU64(-Z) | ◎ | |||

| C200HX-CPU65-Z | ◎ | |||

| C200HX-CPU85-Z | ◎ | |||

| CV series | CV500 | ◎ | ||

| CV1000 | ◎ | |||

| CVM1 | ◎ | |||

| CS1 series | CS1H-CPU67 | ◎ | ||

| CS1H-CPU66 | ◎ | |||

| CS1H-CPU65 | ◎ | |||

| CS1H-CPU64 | ◎ | |||

| CS1H-CPU63 | ◎ | |||

| CS1G-CPU45 | ◎ | |||

| CS1G-CPU44 | ◎ | |||

| CS1G-CPU43 | ◎ | |||

| CS1G-CPU42 | ◎ | |||

| CJ series | CJ1H | ◎ | ||

| CJ1M | ◎ | |||

| CJ1G | ◎ | |||

| CJ2H | ◎ | |||

| CP1 series | CP1H | ○ | ||

| CP1L | ○ | |||

| CP1E | ◎*4 | ○ | ||

| Toshiba Machine*1 | TC mini series | ◎ | ◎ | |

| Models with RS-232C port | Models with RS-485 port | |||

| Yokogawa Electric*1 | FA-M3 series | F3SP59-7S | ◎ | |

| F3SP58-6S | ◎ | |||

| F3SP58-6H | ◎ | |||

| F3SP53-4S | ◎ | |||

| F3SP53-4H | ◎ | |||

| F3SP38-6S | ◎ | |||

| F3SP38-6N | ◎ | |||

| F3SP35-5N | ◎ | |||

| F3SP28-3S | ◎ | |||

| F3SP28-3N | ◎ | |||

| F3SP25-2N | ◎ | |||

| F3SP21-0N | ◎ | |||

| KEYENCE*1 | KV Nano series | ◎ | ||

| KV series | KV-10/16/24/40 | ◎ | ||

| KV700 | ◎ | ○ | ||

| KV1000 | ◎ | ○ | ||

| KV3000 | ◎ | ○ | ||

| KV5000 | ○ | ○ | ||

| Hitachi Industrial Equipment Systems*1 | EH-150 EHV series | EHV-CPU128 | ◎ | ◎ |

| EHV-CPU64 | ◎ | ◎ | ||

| EHV-CPU32 | ◎ | ◎ | ||

| EHV-CPU16 | ◎ | ◎ | ||

| EH-150 series | EH-CPU104A | ◎ | ◎ | |

| EH-CPU208A | ◎ | ◎ | ||

| EH-CPU316A | ◎ | ◎ | ||

| EH-CPU516 | ◎ | ◎ | ||

| EH-CPU548 | ◎ | ◎ | ||

| MICRO-EH series | 10-point | |||

| 14 / 20-point | ◎ | |||

| 23 / 28-point | ◎ | ◎ | ||

| 40 / 64-point | ◎ | |||

| Web controller | 10-point | ◎ | ||

| 23-point | ◎ | ◎ | ||

| Rockwell Automation*1 (Allen-Bradley) Models that support DF protocol | MicroLogix series | MicroLogix500 | ◎ | |

| MicroLogix1000 | ◎ | |||

| MicroLogix1100 | ◎ | |||

| SLC-500 series | SLC-5/03 | ◎ | ||

| SLC-5/04 | ◎ | |||

| Siemens*1 | S7-200 series | CPU222 | ○ | ◎ |

| CPU216 | ○ | ◎ | ||

| CPU215 | ○ | ◎ | ||

| CPU214 | ○ | ◎ | ||

| CPU212 | ○ | ◎ | ||

| LS Industrial Systems*1 | MASTER-K series | 80S / 200S | ◎ | |

| 300S / 1000S | ○ | |||

| Modbus*1 | Models that support RTU protocol | *3 | ◎ | ◎ |

| General-purpose serial*1 | Our dedicated protocol | *3 | ◎ | ◎ |

*1) PLCs other than our FP series may be limited in the type of device that can be used and addresses. Please see manual for details.

*2) Communication may not be possible when using RS-485 depending on the sending and receiving timing with the other device.

*3) We cannot specify what other device you should use; therefore, please test it using the actual equipment before using.

*4) Available for models equipped with on RS-232C port.

◎: Direct connection is possible to the CPU unit of the PLC.

○: Connection is possible using the communications unit or a signal conversion cable, etc.

(Example: The QJ71C24N or QJ71C24N-R2 calculator link unit is required when using the Mitsubishi Q Series.)

Blank: Not evaluated.

Refer to the HELP of the latest version of tool software "Terminal GTWIN", or GT series Connection with other companies' PLC s Manual for more details such as usable devices and addresses.