KW1M-H Eco-POWER METER (Discontinued Products)

Download

-

Discontinued Products

-

System Configuration

-

Rating/ Performance

-

Dimensions

-

Cautions For Use

Ⅾiscontinued

Last time buy

September 29, 2023

------------------------------ Tab1 showing ------------------------------

Discontinued Products

------------------------------ Tab2 showing ------------------------------

System Configuration

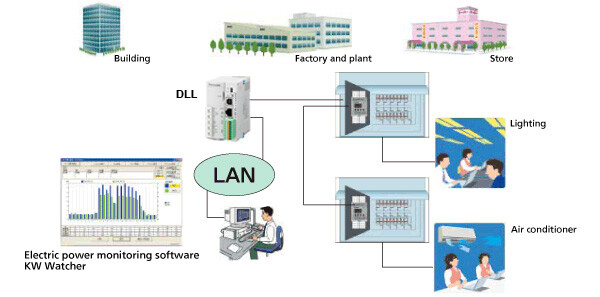

1. Power monitoring of machine

2. Power monitoring of lighting and air conditioner

------------------------------ Tab3 showing ------------------------------

Rating/ Performance

Measurement items

| Item | Unit | Data display range | |

|---|---|---|---|

| Instantaneous electric power (Active) | kW | 0.00 to 9999.99 | |

| Integrated electric power (Active) | kWh/MWh | 0.00 to 9999.99 MWh 0.00 to 9999999.99 kWh (when 9-digit display) | |

| Current | R-current | A | 0.0 to 6000.0 |

| S-current | A | 0.0 to 6000.0 | |

| T-current | A | 0.0 to 6000.0 | |

| Voltage | R (RS)-voltage | V | 0.0 to 9999.9 |

| S (RT)-voltage | V | 0.0 to 9999.9 | |

| T (TS)-voltage | V | 0.0 to 9999.9 | |

| Electricity charge (Note 1) | - | 0.00 to 999999 | |

| Conversion carbon dioxide value | kg-CO2 | 0.00 to 999999 | |

| Power factor | - | 0.00 to 1.00 [Identify leading phase (–) or lagging phase] (Only in range of phase angle θ = –90° to +90°) | |

| Frequency | - | 47.5 to 63.0 Hz | |

| Hour meter | ON-time | h (Hour) | 0.0 to 99999.9 |

| OFF-time | h (Hour) | 0.0 to 99999.9 | |

| Pulse counter | - | 0 to 999999 | |

| Simple demand | Present demand | kW | 0.00 to 9999.99 |

| Estimated demand | kW | 0.00 to 9999.99 | |

| Ratio of estimated demand | % | 0.0 to 9999.9 | |

Note 1:

Eco-POWER METER is designed chiefly to manage saving energy. It is neither intended nor can it be legally used for billing.

General specifications

| Item | Specifications | |

|---|---|---|

| Rated operating voltage | 100 to 240V AC | |

| Rated frequency | 50 / 60 Hz common | |

| Rated power consumption | 8 VA (240 V AC at +25 ℃ +77 ℉) | |

| Allowable operating voltage range | 85 to 264 V AC (85 % to 110 % of rated operating voltage) | |

| Allowable momentary power-off time | 10 ms | |

| Ambient temperature | -10 to +50 ℃ +14 to +122 ℉ (-25 to +70 ℃ -13 to +158 ℉ at storage) | |

| Ambient humidity | 30 to 85 % RH (at +20 ℃ +68 ℉) non-condensing | |

| Breakdown voltage(initial) | Between the isolated circuits : 2000V for 1min | A)Outer edge (case)-All terminals B)Between Insulated circuit ·Operating power supply terminals-Analog input terminals ·Operating power supply terminals-Pulse input terminal ·RS485-All other terminals ·Pulse output terminals-All other terminals |

| Insulation resistance(initial) | Between the isolated circuits : 100MΩor more (measured at 500V DC) | |

| Vibration resistance | 10 to 55Hz (1cycle/min) single amplitude : 0.375mm(1h on 3 axes) | |

| Shock resistance | Min. 294m/s2 (5 times on 3 axes) | |

| Display method | LCD with backlight Upper: green, 4-digit, 16-segment Lower: amber, 6-digit, 7-segment | |

| Power failure memory method | EEPROM (more than 100,000 overwrite) | |

| Weight | 180 g approx.(wihtout battery) | |

Note :

Analog input terminals: No.4, No.5 and No. 6

Electric power input

| Item | Specifications | ||

|---|---|---|---|

| Phase and wire system | Single-phase two-wire system Single-phase three-wire system Three-phase three-wire system Three-phase four-wire system | (common) | |

| Input voltage | Rating | Single-phase two-wire : 0-440V AC (Line voltage) Single-phase three-wire : 0-220V AC (Phase voltage) Three-phase three-wire : 0-440V AC (Line voltage) Three-phase four-wire : 0-254V AC (Phase voltage) | |

| Allowable measurement voltage | Up to 120% of rated input voltage Single-phase two-wire : 0-528V AC (Line voltage) Single-phase three-wire : 0-264V AC (Phase voltage) Three-phase three-wire : 0-528V AC (Line voltage) Three-phase four-wire : 0-300V AC (Phase voltage) | ||

| VT ratio | 1.00 to 99.99 (Set with setting mode) *Voltage transformer (VT) is required when you measure a load with voltage over 440VAC (Allowable measurement voltage). *Secondary current rating of VT is 110V. | ||

| Input current | Primary side rating | <Using the dedicated CT> ・5A/50A/100A/250A/400A/600A (Select with setting mode) <Using a CT with the secondary side current 5A> ・1 to 4000A (Set with setting mode) *Use a CT with secondary side current of 5A when measure 600A or more. | |

| Special functions | Cut-off current | 1.0 to 50.0%F.S (Set with setting mode) | |

| Cut-off voltage | Below 5% of rating voltage (Rating voltage x 0.05 x VT ratio) (Fixed) | ||

| Current threshold for hour meter | 1.0 to 100.0%F.S. | ||

| Accuracy (without error in CT and VT) | Indication accuracy | Instantaneous electric power, Integrated electric power, Conversion electricity charge value, Conversion carbon dioxide value | |

| Within ± (2.0 % F.S. + 1 digit) (at +20 ℃ +68 ℉, rated input, rated frequency, power factor 1) (Note) | |||

| Current | |||

| Within ± (1.0 % F.S. + 1 digit) (at +20 ℃ +68 ℉ rated input, rated frequency, power factor 1) (Note) | |||

| Voltage | |||

| Within ± (1.0 % F.S. + 1 digit) (at +20 ℃ +68 ℉ rated input, rated frequency, power factor 1) | |||

| Hour meter | |||

| Within ± (0.01 % +1 digit) (at +20 ℃ +68 ℉) (In case power on start or current energizing: ± 0.01 % + 1 sec + 1 digit) | |||

| Temperature characteristics | Within ± (1.0 % F.S. + 1 digit) (Range of -10 to +50 ℃ +14 to +122 ℉, rated input, power factor 1) In case of 5 A CT mode, within ± (1.5 % F.S. + 1 digit) under the same condition | ||

| Frequency characteristics | Within ± (1.0 % F.S. + 1 digit) (Frequency change ± 5 % based on rated frequency, rated input, power factor 1) In case of 5 A CT mode, within ± (1.5 % F.S. + 1 digit) under the same condition | ||

Note :

Accuracy coverage: 5 to 100 % of rated current

In case of 5 A CT mode, within ± (2.5 % F.S. + 1 digit) under the same condition

Pulse input specifications

| Item | Specifications | |

|---|---|---|

| Input mode | Addition (Fixed) | |

| Max. counting speed | 2 kHz / 30 Hz (Select with setting mode) (Note 1) | |

| Pulse input (Min. input signal width) | 0.25 ms (When 2 kHz selected) / 16.7 ms (When 30 Hz selected), ON : OFF ratio = 1 : 1 | |

| Input signal (at +20 ℃ +68 ℉) | Contact / No contact (open collector) - Impedance when shorted: Max. 1 kΩ - Residual voltage when shorted: Max. 2 V - Impedance when open: Min. 100 kΩ | |

| Mode | HOLD (Over count) | |

| Prescale | Decimal point | Setting possible up to under 3-digit |

| Range | 0.001 to 100.000 (Set with setting mode) | |

Note 1:

Counting speed will be fixed at 50Hz when you select "pulse through" in the pulse output unit.

Demand monitoring pulse input specifications

| Item | Specifications |

|---|---|

| Input method | Non-voltage pulse input or open-collector input |

| Pulse constant number | 50,000(pulse/kWh)/2,000(pulse/kWh) |

| Minimum pulse width | 0.25ms (2kHz selection) / 16.7ms (30Hz selection) |

| Pulse rate | 0.001 to 100.000 kWh/1pulse |

Specifications of the pulse output (transistor output)

| Item | Specifications |

|---|---|

| Number of output point | 1 point |

| Insulation method | Optical coupler |

| Output type | Open collector |

| Output capacity | 100 mA 30 V DC |

| Pulse width | 100 ms approx. |

| ON state voltage drop | 1.5 V or less |

| OFF state leakage current | 100 μA or less |

| Pulse output unit | 0.001/0.01/0.1/1/10/100kWh/Alarm(AL-P)/ Current alarm(AL-C) /Stand-by alarm (AL-S) /Counter(Cnt) / Demand alarm(DEM) /Pulse through (P-THR) (Selectable with setting mode) |

Note :

We recommend the setting of minimum unit for pulse output for measurement shown as below.

Output pulse: 4 pulse or less per 1sec.

- How to calculate -

(Unit for pulse output: PL-P)>(Max. measurement power [kW])/(3600[s]×4 [pulse/s])

Note 1:

Improper unit setting may cause miss counting.

Note 2:

If the OFF time is too short, there is a possibility of counting errors.

Communication specification

| Item | Specifications |

|---|---|

| RS-485 communication | |

| Protocol | MEWTOCOL and Modbus RTU (selectable with setting mode) |

| Isolation status | Isolated with the internal circuit |

| Number of connected units | Max. 99 units (Note 1) (Note 2) |

| Transmission distance | 1,200 m 3,937 ft (Note 3) |

| Transmission speed | 115200 / 57600 / 38400 / 19200 / 9600 / 4800 / 2400 bps (selectable with setting mode) |

| Transmission format | Data length: 8-bit / 7-bit (selectable with setting mode) (Note 4), Parity: Not available / Odd number / Even number (selectable with setting mode), Stop bit: 1 bit (fixed) |

| Communication method / Synchronous system | Half-duplex / Synchronous communication method |

| Ending resistance | 120 Ω approx. (built-in) |

Note 1:

For RS-485 converter on the computer side, we recommend SI-35 and SI-35USB (from LINE EYE Co.,Ltd.).

Note 2:

When using SI-35,SI-35USB or PLC from our company (which can be connected up to 99 units), up to 99 Eco-POWER METER can be connected. In case using this system with the other devices, up to 31 Eco-POWER METER can be connected.

Note 3:

Please check with the actual devices when some commercial devices with RS-485 interface are connected. The number of connected devices, transmission distance, and transmission speed may be different according to using transmission line.

Note 4:

With Modbus RTU protocol, it works only with 8bit.

* Modbus Protocol is a communications protocol developed for PLCs by Modicon Inc.

Demand power

| Item | Specifications | |

|---|---|---|

| Demand span | 30 minutes span fix | |

| Span system | Synchronized with the main unit clock (synchronized with the frewuency of measured voltage) Time correction; available / not available (selectable with setting mode) | |

| Data update cycle | 1 minute | |

| Power input type | Current transformer (CT) input / Pulse input (Note 1) (selectable with setting mode) | |

| Measurement item | Present demand (update every 1 second), Estimated demand (update every 1 minute) | |

| Display | Present demand, Estimated demand, Demand setting value Ratio of estimated demand Demand log, Monthly max. demand log, Max. demand | |

| Saved data (main unit memory) | Monthly max. demand log 13 records (13 months) Demand log 336 records (7 days) | |

| Demand alarm (Note 2) | Indication | [D] blinking on the upper line |

| Output | 1-circuit Pulse output (pulse output terminal) | |

| Demand alarm stand-by time | 1 to 30 min. | |

| Power Failure Memory | Monthly max. demand log, Demand log, Present demand, Max.demand | |

Note: 1

In order to use demand function by pulse input, input pulse with applicable pulse width according to 8.2.2 Pulse input. If other pulse is input, it doen't work the demand function correctly.

Note 2:

Demand alarm

When the present demand or estimated demand exceeds the setting value, it notifies by the output and the indication. You need to set "DEM" with unit for pulse output setting in order to output.

Note: 3

In case of a power failire, it stops monitoring demand and demand alarm (demand alarm off).

Please use this simple demand function as your standard.

It doesn’t support pulse input. It supports only CT input (power measurement).

The time used by this function is the time set up with Eco-POWER METER.

Therefore, it is different from the demand meter controlled by an electric power company.

Memory specifications of main unit

| Item | Specifications | |

|---|---|---|

| File type 1 (Instantaneous value) (Note) | Save cycle | 60 minutes (Just at every hour) (fixed) |

| Saved data | (Instantaneous value) Integrated electric power, Instantaneous electric power, Current, Voltage, Power factor, Frequency, Count value | |

| Saved data amount | 24 records for 1 file (Max 1.5 years) | |

| File type 2 (Difference value) (Note) | Save cycle | 60 minutes (Just at every hour) (fixed) |

| Saved data | (Difference value) Integrated electric power, Count value | |

| Saved data amount | 24 records for 1 file (Max 1.5 years) | |

| File type 3 (Detail instantaneous value) (Note) | Save cycle | Selectable from 1min, 5min, 10min, 15min, 30min, 60min. (Saved timing) 1min selected: Just at every minute 5min selected: 00,05,10,15,20,25,30min・・・of every hour 10min selected: 00,10,20,30,40,50min of every hour 15min selected: 00,15,30,45min of every hour 60min selected: Just at every hour |

| Saved data | (Instantaneous value) Integrated electric power, Instantaneous electric power, Current, Voltage, Power factor, Frequency, Count value, Electric power converted by pulse, Present demand, Load ON-time, Load OFF-time | |

| Saved data amount | Max. 5760 records about 4 days (In case of 1 min of save cycle) | |

| Display | Monthly integrated electric power (Latest 18 months) Daily integrated electric power (Latest 30 days) Hourly integrated electric power (Latest 24 hours) | |

Note :

You can select if the data of file type 1,2 and 3 is written to SD memory card with setting mode.

Calendar timer specifications

| Item | Specifications |

|---|---|

| Time accuracy | Monthly accuracy: ± 240 sec (at -10 ℃ +14 ℉) Monthly accuracy: ± 70 sec (at +25 ℃ +77 ℉) Monthly accuracy: ± 240 sec (at +50 ℃ +122 ℉) |

| Content of battery backup | Time measurement and log data |

| Battery life | 2 years approx. (at ambient temperature +25 ℃ +77 ℉) (in power-off state) |

External memory specifications <SD memory card slot>

| Item | Specifications |

|---|---|

| Support media | SD memory card (Note 1) |

| Supported format standards | SD / SDHC standard conformance |

Note 1:

Please use the SLC type SD memory card.

DEDICATED CURRENT TRANSFORMER (CT)

Specifications

| Item | Clamp-on typ | ||||

|---|---|---|---|---|---|

| AKW4801B AKW4801C | AKW4802B AKW4802C | AKW4803B AKW4803C | AKW4804B AKW4804C | AKW4808B AKW4808C | |

| CE marking directive compliance | Low Voltage Directive, RoHS Directive | ||||

| Primary side rated current | 5A/50A | 100A | 250A | 400A | 600A |

| Secondary side rated current | 1.67mA/16.7mA | 33.3mA | 125mA | 200mA | 200mA |

| Winding (Turn) | 3000 | 3000 | 2000 | 2000 | 3000 |

| Ratio error | ±2.0%F.S. | ||||

| Through hole | ø10 ø0.39 | ø16 ø0.63 | ø24 ø0.94 | ø36 ø1.42 | ø36 ø1.42 |

| Breakdown voltage (initial) | 1000V AC/1min (Between through hole and output lead wire) | 2000V AC/1min (Between through hole and output lead wire) | |||

| Insulation resistance (initial) | Min. 100 M Ω (at 500 V DC) (Between through hole and output lead wire) | ||||

| Functional vibration resistance | 10 to 55 Hz (1 cycle / min), single amplitude: 0.15 mm 0.01 in (10 min on 3 axes) | ||||

| Vibration resistance | 10 to 55 Hz (1 cycle / min), single amplitude: 0.375 mm 0.01 in (1 hour on 3 axes) | ||||

| Functional shock resistance | Min. 98m/s2(4 times on 3 axes) | ||||

| Shock resistance | Min. 294m/s2(5 times on 3 axes) | ||||

| Output protection level | ±7.5 V with clamp element | ±3.0V with clamp element | |||

| Permissible clamping frequency | 100 times approx. | ||||

| Ambient temperature range | -10 to +50℃ +14 to +122 ℉ (without frost and non-condensing) | ||||

| Storage temperature | -20 to +60℃ -4 to +140 ℉ (without frost and non-condensing) | ||||

| Ambient humidity | 35 to 85%RH(at +20℃ +68 ℉ non-condensing) | ||||

| Dimensions (mm in) (W x H x D) | 23 x 40 x 26.5 0.08 x 0.13 x 0.09 | 30 x46.5 x 32 0.10 x 0.15 x 0.11 | 45 x65 x 34 0.15 x 0.21 x 0.11 | 57 x81 x 38 0.19 x 0.27 x 0.12 | 62.6 x93.3 x 40 0.21 x 0.31 x 0.13 |

| Weight (Relay cable included) | 60 g approx. | 90 g approx. | 200 g approx. | 295 g approx. | 450 g approx. |

| Item | Through type | |||

|---|---|---|---|---|

| AKW4506B AKW4506C | AKW4507B AKW4507C | AKW4508B AKW4508C | ||

| CE marking directive compliance | Low Voltage Directive, RoHS Directive | |||

| Primary side rated current | 50A/100A | 250A/400A | 600A | |

| Secondary side rated current | 16.7mA/33.3mA | 125mA/200mA | 200mA | |

| Winding (Turn) | 3000 | 2000 | 3000 | |

| Ratio error | ±1.0%F.S. | |||

| Through hole | ø17mm ø0.67 in | ø36mm ø1.42 in | ||

| Breakdown voltage (initial) | 1000V AC/1min (Between through hole and output lead wire)) | 2000V AC/1min (Between through hole and output lead wire) | ||

| Insulation resistance (initial) | Min. 100 MΩ (at 500 V DC megger) (Between through hole and output lead wire) | |||

| Functional vibration resistance | 10 to 55 Hz (1 cycle / min), single amplitude: 0.15 mm 0.01 in (10 min on 3 axes) | |||

| Vibration resistance | 10 to 55 Hz (1 cycle / min), single amplitude: 0.375 mm 0.01 in (1 hour on 3 axes) | |||

| Functional shock resistance | Min. 98 m/s2 (4 times on 3 axes) | |||

| Shock resistance | Min. 294 m/s2 (5 times on 3 axes) | |||

| Output protection level | ±7.5 V with clamp element | ±3.0 V with clamp element | ||

| Permissible clamping frequency | - | |||

| Ambient temperature range | –10 to +50 ℃ +14 to +122 ℉ (without frost and non-condensing) | |||

| Storage temperature | –20 to +60 ℃ –4 to +140 ℉ (without frost and non-condensing) | |||

| Ambient humidity | 35 to 80 % RH (at +20 ℃ +68 ℉non-condensing) | |||

| Dimensions (mm in) (W x H x D) | ø42 x 15 1.65 x 0.05 | ø70 x19 2.76 x 0.06 | ø70 x19 2.76 x 0.06 | |

| Weight (Relay cable included) | 70 g approx. | 200 g approx. | 215 g approx. | |

Notes :

1)

Dedicated CT are dedicated for low voltage under 440 V AC system. They can not be used for high voltage circuit.

2)

In each type of Eco-POWER METER excluding AKW8115, KW9M and KW2M, a combination of commercially secondary side 5 A CTs and dedicated CTs for 5 A is used for measuring high voltage circuits; For details, confirm with each respective user's manual.

3)

Since dedicated CTs cannot be used when measuring with AKW8115, KW9M and KW2M, please be careful and do not purchase a dedicated CT by mistake.

4)

For the AKW8115, KW9M and KW2M, CT with a secondary side current 1 A or 5 A is recommended. Please confirm the specification beforehand.

5)

Dedicated CT are not included with Eco-POWER METERs.

6)

Each dedicated CT includes a 1 m 3.281 ft relay cable, respectively.

------------------------------ Tab4 showing ------------------------------

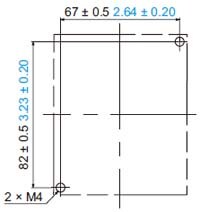

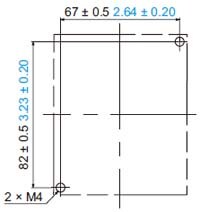

Dimensions

- Unit: mm in

KW1M-H

AKW1121B

Mounting hole dimensions

Note : Please keep space that the thumb enters for the battery exchange at the left of the main unit (about 30mm).

Dedicated current transformers CT

Dedicated current transformer (CT) Clamp-on type 5A/50A (AKW4801B)

Dedicated current transformer (CT) Clamp-on type 100A (AKW4802B)

Dedicated current transformer (CT) Clamp-on type 250A (AKW4803B)

Dedicated current transformer (CT) Clamp-on type 400A (AKW4804B)

Dedicated current transformer (CT) Clamp-on type 600A (AKW4808B)

Dedicated current transformer (CT) Through type 50A/100A (AKW4506B)

Dedicated current transformer (CT) Through type 250A/400A/600A (AKW4507B/AKW4508B)

Terminal arrangement・Wiring diagrams

Terminal arrangement

Be sure to wire correctly according to the terminal arrangement and wiring diagrams.

After completing wiring, be sure to attach the terminal cover for safety reasons.

Caution for Wiring

1) Terminal fastening torque should be 0.5 to 0.6N・m. In case of using a crimping terminal, use it with insulating sleeve applicable to M3 screw.

2) This has no built-in power switch, circuit breaker for power supply part. To protect the device, it is necessary to install power switch and circuit breaker in the power supply circuit.

And this has no built-in power switch, circuit breaker or fuse for measured voltage input parts.

Therefore it is necessary to install them in the circuit near this unit.

3) We recommend a wire with the cross section of 0.75 to 1.25mm2 for power supply line and measured voltage input line.

4) Use flame-resistant cable for each wiring.

Wiring diagrams

When measuring load with rated input voltage (100 to 200 V AC system and 400 V AC system)

·Single-phase two-wire system

*One dedicated current transformer (CT) is required.

Note: Do not wire to (6), (7) terminal. They are connected internal.

·Single-phase three-wire system / Three-phase three-wire system

*Two dedicated current transformers (CT) are required.

Note: Do not wire to (7) terminal.They are connected internal.

·Three-phase four-wire system

*Three dedicated current transformers (CT) are required.

When measuring a load with exceed input voltage

Voltage transformer (VT) is needed when you measure a load with over rated input voltage (440V).Use VT, those secondary rating is 110V.

Grounding the secondary side of VT and CT is not necessary with low-voltage circuit.

- Single-phase two-wire system

- Single-phase three-wire system / Three-phase three-wire system

- Three-phase four-wire system

Discontinued products [Order accepted till December, 2016]

AKW1121

Mounting hole dimensions

Dedicated current transformer (CT) Clamp-on type 5A/50A (AKW4801C)

Dedicated current transformer (CT) Clamp-on type 100A (AKW4802C)

Dedicated current transformer (CT) Clamp-on type 250A (AKW4803C)

Dedicated current transformer (CT) Clamp-on type 400A (AKW4804C)

Dedicated current transformer (CT) Clamp-on type 600A (AKW4808C)

Dedicated current transformer (CT) Through type 50A/100A (AKW4506C)

Dedicated current transformer (CT) Through type 250A/400A/600A (AKW4507C/AKW4508C)

|

|

| |||||||||

------------------------------ Tab5 showing ------------------------------

Cautions For Use

*Please refer to each manual for the precautions in using.

Avoid locations subject to flammable or corrosive gases, excessive dust, oil, vibrations, or excessive shocks.

Although the case is made from fireproof resin, do not mount it next to flammable materials. Also, avoid placing it directly on top of materials that catch fire easily.

Since the cover for main unit is made of polycarbonate resin, avoid contact with or use in environments containing methyl alcohol, benzene, thinners, and other organic solvents; and ammonia, caustic sodas, and other alkaline substances.

This product is designed to be used only with our options. Options from other companies are not compatible.

Measurement

- Accurate measurement may not be possible if harmonics or waveforms are distorted. Therefore, please test on actual equipment before using.

- Do not use the secondary circuit of the inverter. It causes heat and malfunctions in the main unit.

Surge

- If the operating power supply surge exceeds the following value, the internal circuit could be destroyed, so be sure to use a surge absorption element.

| Surge voltage | KW1M series | Other series |

|---|---|---|

| 4,000 V | 6,000 V |

The values in the graph are the surge-voltage resistance at ±(1.2 × 50) μs of single-polarity full-wave voltage.

Surge wave form [±(1.2/50) μs single-polarity full-wave voltage]

- External noise up to the level shown below is treated as noise voltage, but levels higher than this could lead to malfunctioning or damage to the internal circuit.

| Operating power supply terminals | |

|---|---|

| Noise voltage | 1,500V |

Noise wave form (noise simulator)

Rise time: 1 ns Pulse width: 1 μs, 50 ns

Polarity: ± Cycle: 10 ms

(Note 1): Accurate measurement may not be possible if excessive noise gets added to the input line.

Self-diagnostic function

If an error occurs, the following displays will be given.

| Display | Meaning | Output status | Restoration procedure | Status after restoration |

|---|---|---|---|---|

| ERR00 | CPU error | OFF | Turn the power off and then on again. | The display at start-up before the CPU malfunction occurred. |

| ERR01 | Memory error (Note 2) | EEPROM life ended. Replace the main unit. | - |

(Note 2):

Includes the possibility that the EEPROM's life has expired.

Power failure memory

- Eco-POWER METER memories integrated electric power and working status to internal EEPROM until when power supply is off. (Power failure guarantee)

And every time to change each setting, each setting value is memorized to internal EEPROM at the same time. Therefore, change setting frequently makes EEPROM's life short. Avoid to usage like this.

Others

- Eco-POWER METER is designed chiefly to manage saving energy. It is neither intended nor can it be legally used for billing.

Wiring

Please make sure to check wiring in dimensions page in each product page.

Note:

Please connect a breaker (3 to 15A) to the voltage input part for safety reasons and to protect the device. Grounding the secondary side of VT (Voltage transformer) and CT (Current transformer) is not necessary with low-voltage circuit.

Regarding dedicated current transformers(In AKW8115, dedicated current transformers are not used,therefore, please confirm the respective user's manual.)

HOW to attach the Current Transformer (CT)

- In case the Eco-POWER METER has connectors for CT, connect to the Eco-POWER METER as it is.

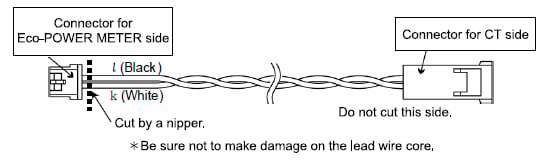

- In case the Eco-POWER METER has screw terminals for CT (KW4M and KW8M), cut the connector for Eco-POWER METER side. Refer to the below.

<Process drawings>

- The below number of CT is required.

For single-phase, two-wire system; 1 pc.

For single-phase, three-wire system; 2 pcs.

For three-phase, three-wire system; 2 pcs.

For three-phase, four-wire system; 3 pcs.

All using CT for one Eco-POWER METER should have the same rating. - Check beforehand that the thickness of the load electric wire is smaller than the through hole of the CT.

- Do not attach CT to the part which a conductor is exposed, such as a bus bar in a control box.

It might cause an electric shock. - When connecting CT, connect the secondary side to the terminal of the Eco-POWER METER first, and after that wire the primary side to a load electric wire. Incorrect order might cause an electric shock or break CT.

- CT has polarity. Align according to the direction (K → L) written on the CT and install from the power source side (K) facing the load side (L). If the direction is incorrect, accurate measurement is impossible.

- When installing and closing CTs, please confirm there is no dust or foreign matter on the separating surfaces. In addition, verify that the separating surfaces are making perfect contact when the CT is closed. Measurement errors will occur if there is a gap in the separating surfaces. (Only Clamp-on type)

- If there is some distortion by harmonic or waveform, it may not measure correctly. Please check with the actual system before adopting it.

- Separate the wiring (strong electric part) of the measured voltage input terminal (operating power supply terminal) from the CT cable. It may not satisfy the accuracy due to noise.

When CT's cable is extended

- Extension of the cable is possible up to approximately 10 m 32.808 ft if the environment is completely free from noise such as external and line induction noise, and the cable has a thickness of at least 0.75 mm2. When extending the cable, use as thick a cable as possible.

*When extending the cable, please perform testing under actual conditions before using.

To connect CT with secondary side current 5 A

How to connect for measuring by combination with CT (secondary side current 5 A)

- Select 5 A at CT type setting mode (CT-T).

- Set the primary current of measured CT (secondary side current 5 A) at primary side current of CT setting mode (CT-1). If the measured CT is 400 A / 5 A, set to "400".

- Clamp the dedicated CT for 5 A, which is connected to the main unit first, to secondary side of the CT. CT direction (K → L) should be set for the CT direction.

- Please set the CT (secondary side current 5 A CT) and, the dedicated CT for 5A, approximately 1 m 3.281 ft apart. If the two CTs are set too close each other, it may not measure accurately due to magnetic field interference.

(Connection example)

With ammeter etc.

Without ammeter

Input connection [except AKW7111B and AKW1110B]

- Contact input

Use highly reliable metal plated contacts. Since the contact's bounce time leads directly to error in the count value, use contacts with as short a bounce time as possible. In general, select 30 Hz for max. counting speed. - Non-contact input (Transistor input)

Connect with an open collector. Use the transistor with the following specifications.

VCEO=min. 20 V, IC=min. 20 mA, ICBO= max. 6 μA

Use transistors with a residual voltage of less than 1.5 V when the transistor is ON.

Note:

Short-circuit impedance should be less than 1 kΩ. (When the impedance is 0 Ω, drain current is approx, 7 mA. The opencircuit impedance should be more than 100 KΩ.)

- Input wiring

Please use shielded wire or metal wire-ways exclusively and a wire length of 10 m 32.808 ft or less. If the wiring length is longer, the impact due to floating capacitance may result in abnormal operation.

Note:

Operating power supply input part and measured voltage input are not insulated to pulse input parts.So the input equipment must have the power supply transformer in which the secondary side is not grounded with the primary and secondary sides insulated, in order to prevent interference of the power supply circuit when connecting the external input circuit. Be sure not to use an auto-transformer.

Output connection

Since the transistor output is insulated from the internal circuit by a photo-coupler, it can be used both as a NPN output and PNP (equal value) output.

Crimping terminal

please make sure to check crimping terminal in dimensions page in each product page.

Low Voltage Directive

When using in the application confirming to EN61010-1/IEC61010-1, make sure to satisfy the following conditions.

(1)

Pulse output part secure only basic insulation. In order to secure reinforced (double) insulation demanded by EN 61010-1/ IEC61010-1, secure basic insulation or more with load side and reinforced (double) insulation with communication system side.

(2)

Provide the voltage input part with an EN60947-1 or EN60947-3 compliant circuit breaker. The breaker that connects to the voltage input part must arrange at the position easily reached, and display shows it is the breaker of the equipment.

(3)

Use a wire with basic insulation or more for a wire cramped (or connected) CT.

【Environmental conditions】

- Overvoltage category II, Pollution degree 2

- Indoor use

- An ambient temperature of –10 to 50℃

- An ambient non-condensing humidity of 35 to 85%RH (at 20℃)

- Altitude of 2000m or less

【Mount the product in a place with】

- A minimum of dust, and an absence of corrosive gases

- No flammable, explosive gasses

- Few mechanical vibrations or shocks

- No exposure to direct sunlight

- No large capacity electromagnetic switches or cables through which large current is flowing