KC2S/KE2S (Discontinued Products)

Download

-

Discontinued Products

-

Rating/ Performance

-

Dimensions

-

Cautions For Use

Ⅾiscontinued

Last time buy

September 29, 2023

Discontinued Products

Rating/ Performance

1.Main units

| Item | Specifications | ||

|---|---|---|---|

| Eco-COUNT METER (Power-on Counter) | Eco-HOUR METER (Power-on Hour Meter) | ||

| AKC2421/AKC2621 | AKE2421/AKE2621 | ||

| No. of digits | 8 digits | 6 digits | |

| External power supply | Not required (built-in battery) | ||

| Counting max. speed | 2Hz (CT through current minimum power-up time: 250ms, ON:OFF =1:1) | - | |

| Time accuracy | - | ±100ppm (25℃) | |

| Measurement range | 0 to 99999999 counts | 0 to 99999.9h | |

| Detection sensitivity (through current) | Counting start: 0.5A to 80A (50/60Hz)*1 | Timing start: 0.5A to 80A (50/60Hz)*1 | |

| Counting stop: 0.2A (50/60Hz) or less | Timing stop: 0.2A (50/60Hz) or less | ||

| Reset input | Min. input signal width | 100ms | |

| Input method (signal) | • Non voltage input using contacts or open collector connection • Input impedance, When shorted: Max.10kΩ, When open: Min.750kΩ • Residual voltage: Max. 0.5V | ||

| Display method | 7-segment LCD | ||

| Breakdown voltage (initial) | Between live and dead metal parts: 1,000V AC for 1 minute. | ||

| Insulation resistance (initial) | Between live and dead metal parts: Min. 100MΩ (measured at 500 V DC) | ||

| Protective construction | IEC Standard IP66 (only front panel with rubber gasket) | ||

| Vibration resistance (Functional) | 10 to 55 Hz: 1 cycle/min., signal amplitude of 0.15mm .006inch (10 min. on 3 axes) | ||

| Vibration resistance (Destructive) | 10 to 55 Hz: 1 cycle/min., signal amplitude of 0.375mm .015inch (1 hr. on 3 axes) | ||

| Shock resistance (Functional) | Min. 98m 321.522ft/s2 (4 times on 3 axes) | ||

| Shock resistance (Destructive) | Min. 294m 964.567ft/s2 (5 times on 3 axes) | ||

| Operating temperature | –10 to +50℃ +14 to +122℉ (without frost or dew) | ||

| Storage temperature | –25 to +65℃ –13 to +149℉ (without frost or dew) | ||

| Ambient humidity | 35 to 85% RH (at 20℃ non-condensing) | ||

| Battery life *2 | 7 years (at 25℃ 77℉) | 10 years (at 25℃ 77℉) | |

| Mass (weight) | Approx. 110g (Dedicated CT included) | Approx. 105g (Dedicated CT included) | |

*1 Maximum cable diameter is 10 mm.

*2 Battery life is calculated based on the above conditions.

This is not a guarantee of actual battery life.

Please use this as a guide for replacing the battery only.

The actual battery life may be shortened, depending on the utilization environment of the main unit.

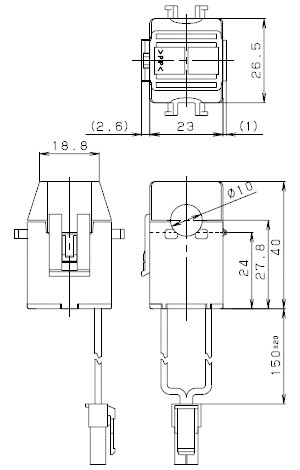

2.Dedicated CT

| Item | Specification |

|---|---|

| Diameter of conductor to be measured | 10 dia. (max.) |

| Breakdown voltage (Initial value) | 1,000 Vrms AC for 1min: Between core and output connector terminal |

| Insulation resistance (Initial value) | Min. 100MΩ: Between core and output terminal (at 500V DC) |

| Allowable number of detachments/attachments | Approx. 100 times |

| Vibration resistance (Functional) | 10 to 55 Hz: 1 cycle/ min single amplitude of 0.15 mm .006 inch (10 min on 3 axes) |

| Vibration resistance (Destructive) | 10 to 55 Hz: 1 cycle/ min single amplitude of 0.375 mm .015 inch (1 h on 3 axes) |

| Shock resistance (Functional) | Min. 98 m 321.522 ft./s2 (4 times on 3 axes) |

| Shock resistance (Destructive) | Min. 294 m 964.567 ft./s2 (5 times on 3 axes) |

| Operating temperature range | –10℃ to +50℃ +14℉ to 122℉ (Without frost or dew) |

| Storage temperature | –20℃ to +60℃ -4℉ to 140℉ (Without frost or dew) |

| Mass (Weight) | Approx. 55g 1.94oz (trunk cable included) |

| Ambient humidity | 35 to 80% R.H. (at 20°C non-condensing) |

*1 For Eco-COUNT METER and Eco-HOUR METER, this CT is supplied together.

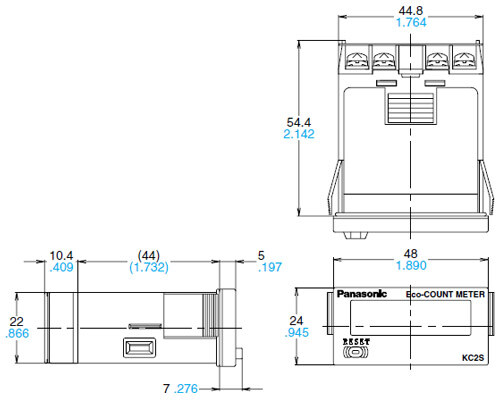

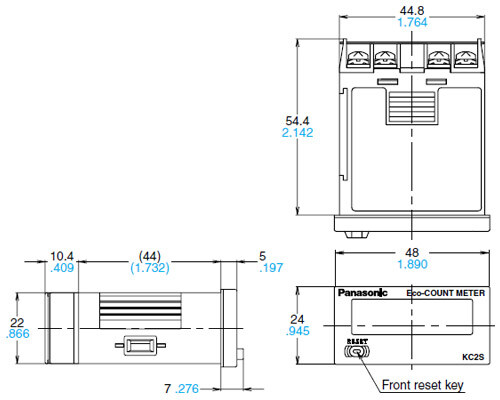

Dimensions

- Unit: mm in

1.Main unit

One touch installation type(AKC2621/AKE2621)

Installation frame type(AKC2421/AKE2421)

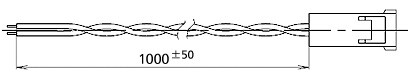

2.Dedicated CT

3.Trunk Cable

Note: The trunk cable connects the main unit and dedicated CT.It is included with the main unit.

Cautions For Use

1.Main unit

1) Reset input

(1) Never apply voltage to reset input. This can cause damage to the internal elements.

(2) Since the current flow is very small from reset input terminal 3, please use relays and switches with high contact reliabillity.

When inputting a reset by a transistor’s open collector use a transistor for small signals in which ICBO is 1μA or less and always input with no voltage.

(3) When wiring, try to keep all the input lines to the reset inputs as short as possible and avoid running them together with high voltage and power transmission lines or in a power conduit.

Note that power cable floating capacitance in excess of 500 pF (10m on 2 mm2 parallel cables) could cause malfunctions. Take particular care of inter-cable capacitance when using shielded cables.

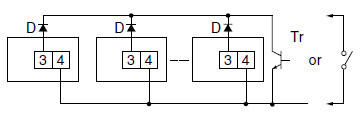

2) How to reset multiple panel installation type units all at once.

Note 1:Use the following as a guide for choosing transistors used for input (Tr).Leakage current < 1μΑNote 2:Use as small a diode (D) as possible in the forward voltage so that the voltage between terminals 3 and 4 during reset input meets the standard value (0.5V).(At IF = 20μA, forward voltage 0.1 V or less.)

2.Dedicated CT

1) Measured power is AC (50 Hz/60 Hz).

Will not function when used with DC power.

2) When clamping to the power cable to be measured, clamp only one of the live wires.

3) Avoid usage that bends the lead wire.

4) When clamping, make sure that no dust or other foreign matter intercedes between the clamp and contact. Foreign matter could impact detection sensitivity.

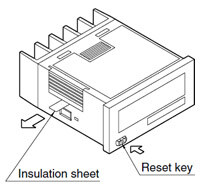

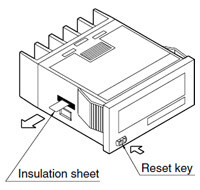

3.Insulation sheet

Before using, please pull and remove the insulation sheet in the direction of the arrow.

In consideration that the product might be stored for long periods without being used, an insulation sheet is inserted before shipping.

Remove the insulation sheet and press the front reset key.

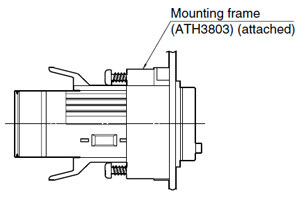

Installation frame type

One-touch installation type

4.Waterproof construction

The operation part is constructed to prevent water from entering the unit and a rubber gasket is provided to prevent water from

entering the gap between the unit and the panel cutout.

There must be sufficient pressure applied to the rubber gasket to prevent water from entering.

Be sure to use the mounting screws when using the mounting frame (ATH3803).

Attaching the one-touch installation type to a panel will not waterproof the panel surface.

5.Do not use in the following environments

- 1) In places where the temperature changes drastically.

- 2) In places where humidity is high and there is the possibillity of dew. (When dew forms the display may vanish and other display errors may occur.)

6.Cautions regarding battery replacement

- 1) Remove wiring before replacing the battery.

You may be electrocuted if you come into contact to a part where high voltage is applied. - 2) Make sure you are not carrying a static electric charge when replacing the battery.

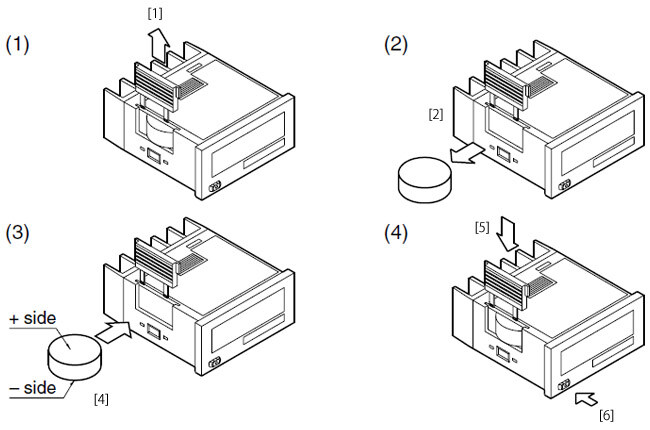

- 3) Battery replacement procedure

• Installation frame type

(1) Remove the battery cover [1] from the case.

(2) Remove the battery [2] from the side of the case.

The battery will come loose if you put the battery side face down and lightly shake the unit.

(3) Before inserting wipe clean the surface of the battery.

Insert the battery [4] with the + and – sides in the proper position.

(4) After replacing the battery return the battery cover [5] to the case. Verify that the hook of the battery cover is properly engaged.

Before using press the reset key [6] on the front.

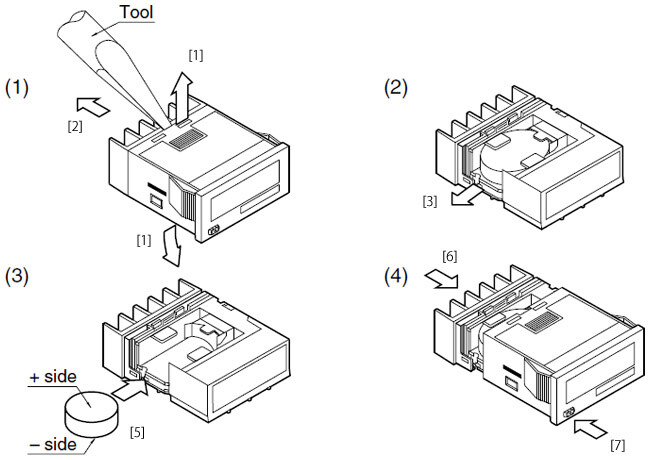

• One-touch installation type

(1) Using a tool remove the up/down hook of the case [1].

Pull the unit [2] away from the case.

(2) Remove the battery [3] from the side of the unit. Do not touch the display or other parts.

(3) Before inserting wipe clean the surface of the battery.

Insert the battery [5] with the + and – sides in the proper position.

(4) After replacing the batery return the unit [6] to the case. Verify that the hook of the case has properly engaged.

Before using press the reset key [7] on the front.