KT2 Temperature Controllers (Discontinued Products)

Download

-

Discontinued Products

-

Number System

-

Rating/ Performance

-

Dimensions

-

Wiring/ Connection

-

Cautions For Use

Ⅾiscontinued

Last time buy (JST)

September 29, 2023

We are sorry, the products have been discontinued. Please refer to the details of the discontinued products and the recommended substitutes list below.

Discontinued Products

Number System

Notes:

1) When heating / cooling is selected, alarm output 1 cannot be used.

2) When the communication function is selected, alarm output 2 cannot be used.

Model No. search method

Example: Basic functions + optional functions (Heating / cooling: relay contact output + communication function)

• For KT2 series, the option function is only the following 4 patterns.

AKT2*1*200 Blank AKT2*1*1001

AKT2*1*110 Blank AKT2*1*0101

• Model No.: AKT21110101

Rating/ Performance

Rating And Specifications

| Display | Specifications | |||

|---|---|---|---|---|

| KT2 | ||||

| CE marking directive compliance | Low Voltage Directive, EMC Directive, RoHS Directive | |||

| Size | 48×24mm 1.890×0.945 in | |||

| Rating | Supply voltage (Must be specified) | 100 - 240V AC | ||

| 24V AC/DC | ||||

| Frequency | 50/60Hz | |||

| Rating power consumption | 5 VA approx. | |||

| Rated scale | Input type | Input range | ||

| Thermocouple | K | -200 to 1,370℃(-320 to 2500℉) | ||

| -199.9 to 400.0℃(-199.9 to 750.0℉) | ||||

| J | -200 to 1,000℃(-320 to 1800℉) | |||

| R | 0 to 1,760℃(0 to 3200℉) | |||

| S | 0 to 1,760℃(0 to 3200℉) | |||

| B | B0 to 1820℃(0 to 3300℉) | |||

| E | -200 to 800℃(-320 to 1500℉) | |||

| T | -199.9 to 400.0℃(-199.9 to 750.0℉) | |||

| N | -200 to 1,300℃(-320 to 2300℉) | |||

| PL-II | 0 to 1,390℃(0 to 2500℉) | |||

| C(W/Re5-26) | 0 to 2315℃(0 to 4200℉) | |||

| RTD | Pt100 | -200 to 850℃(-300 to 1500℉) | ||

| -199.9 to 850.0℃(199.9 to 999.9℉) | ||||

| JPt100 | -200 to 500℃(-300 to 900℉) | |||

| -199.9 to 500.0℃(-199.9 to 900.0℉) | ||||

| DC Current | 4 to 20mA DC | -1,999 to 9,999, -199.9 to 999.9 -19.99 to 99.99, -1.999 to 9.999 | ||

| 0 to 20mA DC | ||||

| DC Voltage | 0 to 1V DC | |||

| 0 to 10V DC | ||||

| 1 to 5V DC | ||||

| 0 to 5V DC | ||||

| · Scaling and change to the decimal point position is possible for DC current input and DC voltage input. · DC current input is supported with an externally connected 50Ω shunt resistor (sold separately). | ||||

| Sensor input | Thermocouple | K, J, R, S, B, E, T, N, PL-II, C (W/Re5-26) External resistor: Max. 100Ω (max. 40Ω external resistor for B input) | ||

| RTD | Pt100, JPt100 3-conductor system (Allowable input conductor resistance for each conductor: max. 10Ωor less) | |||

| DC current | 0 to 20mA DC | Input impedance: 50Ω (Connect 50Ω shunt resistor between input terminals.) Allowable input current: 50 mA or less (When 50Ω shunt resistor is used) | ||

| 4 to 20mA DC | ||||

| DC voltage | 0 to 1V DC | Input impedance: 1 MΩ or more, Allowable input voltage: 5 V or less, Allowable signal source resistance: 2 kΩ or less | ||

| 0 to 5V DC | · 0 to 5 V DC, 1 to 5 V DC, 0 to 10 V DC Input impedance: 100 kΩ or more, 1 to 5 V DC Allowable input voltage: 15 V or less, Allowable signal source resistance: 100 Ω or less | |||

| 1 to 5V DC | ||||

| 0 to 10V DC | ||||

| Control output | Relay contact | (Must be specified) | 1a | |

| 3 A 250 V AC (at resistive load), 1 A 250 V AC (at inductive load cos ø = 0.4), Electrical life: 100,000 times | ||||

| Non-contact voltage (Voltage output for SSR drive ) | 12+20 V DC, Max. load current: 40mA (with short circuit protection circuit) | |||

| DC current | 4 to 20mADC Load resistance: Max. 550Ω | |||

| Alarm output 1 (EV1) | Relay contact 1a 3A 250V AC (Resistive load), 1a 1A 250V AC (cosø=0.4) | |||

| Alarm output 2 (EV2) | Open collector 0.1A 24V DC | |||

| Control method | PID action (with auto-tuning function), PI action, PD action (with manual reset function), P action (with manual reset function), ON / OFF action | |||

| Target temperature setting | Primary setting/secondary setting (switched by external terminal) | |||

| Program control function | 1 pattern, 9-step setting is possible (However, make function selection setting of either control with fixed set point or program control.) | |||

| Accuracy | Thermocouple | Within ± (0.2 % + 1 digit) of each input span or within ±2℃ (4℉) whichever is greater However, R or S input; within ±6℃ (12℉) in the range of 0 to 200℃ (32 to 392℉) B input, range of 0 to 300℃ (32 to 572℉): accuracy is not guaranteed K, J, E, T, and N input, less than 0℃ (32℉): within ± (0.4 % ±1 digit) of input span | ||

| RTD | Within ±(0.1 % + 1 digit) of each input span or ±1℃ (2℉) whichever is greater | |||

| DC current and DC voltage | Within ±0.2% ±1 digit of each input span | |||

| Sampling period | 250ms | |||

| Hysteresis | Thermocouple and RTD: 0.1 to 100.0℃ (℉) DC current and DC voltage: 1 to 1,000 (The decimal point place follows the selection) | |||

| Proportional band | For sensor input range and DC current,DC voltage 0.0 to 110.0% | |||

| Integral time | 0 to 1,000 seconds | |||

| Derivative time | 0 to 300 seconds | |||

| Proportional cycle | 1 to 120 seconds | |||

| Allowable voltage fluctuation | When 100-240 V AC: 85-264 V AC, When 24 V AC/DC: 20-28 V AC/DC | |||

| Insulated resistance | 500 V DC, Min. 10 MΩ | |||

| Breakdown voltage | Between input terminal and power terminal Between output terminal and power terminal 1.5 kV AC for 1 min. | |||

| Malfunction vibration | 10 to 55 Hz (1 cycle/min.), single amplitude: 0.35 mm 0.014 in (10 min. on 3 axes) | |||

| Breakdown vibration | 10 to 55 Hz (1 cycle/min.), single amplitude: 0.75 mm 0.030 in (1 hour on 3 axes) | |||

| Malfunction shock | X, Y and Z each direction for 5 times 98 m/s2 | |||

| Breakdown shock | Same as above, but 294 m/s2 | |||

| Ambient temperature | 0 to 50℃ 32 to +122℉ | |||

| Ambient humidity | 35 to 85%RH (No condensation) | |||

| Mass | 120 g approx. | |||

| Waterproof | IP66 (applicable only to the front panel subject to rubber gasket employed) | |||

| Display character height | PV: 8.7 mm 0.342 in SV: 8.7 mm 0.342 in (PV / SV switching display) | |||

| Option functions | Heating / Cooling control | Relay contact | Relay contact: 1a 3 A 250 V DC (at resistive load) | |

| Non-contact voltage | - | |||

| Heater burnout alarm output | - | |||

| Communication function | Please refer below to “Communication Function Overview”. | |||

| Accessories | Mounting frame / Mounting bracket | Included with controller | ||

| Terminal cover | Sold separately | |||

| Rubber gasket | Included with controller | |||

Communication Function Overview

| Item | Specification |

|---|---|

| Communication method | Half-duplex |

| Communication speed | Select 2,400, 4,800, 9,600, or 19,200 bps using key operation. |

| Synchronization type | Asynchronous |

| Protocol | Modbus |

| Coding | ASCII |

| Error correcting | Parity check and check sum |

| Error detection | Parity check, check sum |

| Data structure | Start bit: 1 Data bit: 7 Parity: Even parity Stop bit: 1 |

| Interface | EIA RS-485 compliant |

| No. of nodes | 31 |

| Maximum cable length | 1,000 m 3,280.840 ft(cable resistance must be within 50Ω |

Dimensions

- Unit: mm in

Note: The communications terminal is the screw terminal on the back of the controller.

Panel cut-out dimensions

Tolerance: ±1±0.039

AKT2801

Terminal Cover

CT1

Current transformer (CT) (for 5, 10, and 20A)

CT2

Current transformer (CT) (for 50 A)

Note:

Current transformer CT1 or CT2 is included (only with KT7 and KT4H)

when heater burnout alarm function is added.

AKT4810

Shunt resistor

Wiring/ Connection

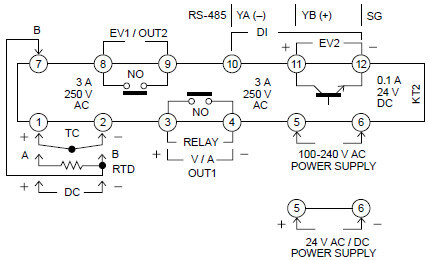

External Connection Diagram

TC : Input terminal for thermocouple

RTD : Input terminal for the resistance temperature detector

DC : Input terminal for DC current or DC voltage.

For DC current input, connect a separately sold reception resistor (50Ω) between the input terminals.

OUT1 : Output terminal for the control output or heating output [optional: heating/cooling control].

POWER SUPPLY : Power supply terminal.

EV1/OUT2 : Output terminal for alarm output 1 or cooling output [optional: heating/cooling control].

EV2 : Output terminal for alarm output 2.

D1 : Input terminal for DI input (There are three types of DI input, SV1 / SV2 external switching function, OUT / OFF (RUN / STOP) external switching function, and timer function)

RS-485 : Communication terminal for serial communication.

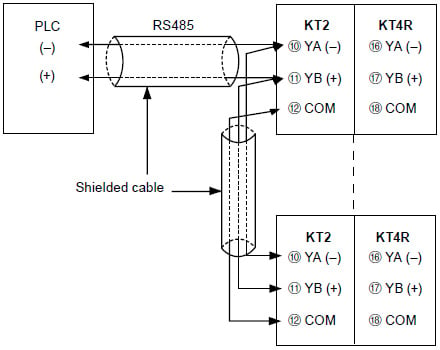

COMMUNICATION FUNCTION CONNECTION DIAGRAM (PLC Connection Diagram)

Note:Terminating resistors (Terminators)The KT series has a built-in pull-up resistor or pull-down resistor, which serves as the terminating resistor.For this reason, do not connect the terminating resistor on the communication line.

Cautions For Use

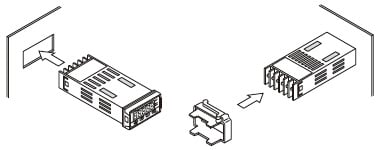

Mounting

Please install vertically in order to satisfy the IP66 specification for dust and splash proofing.

The possible control panel plate thickness for installation is between 1 to 10 mm 0.039 to 0.394 in.

(1)Insert the unit from the front of the control panel.

(2)Insert the mounting frame until that the two edges make contact with the panel.

(3)Tighten the screw and then turn it 3/4 of a turn after the edge of the screw reaches the panel.

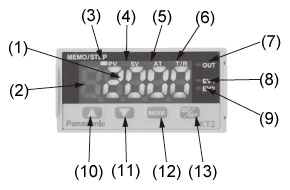

Part description

Note: Color selection is the same for each size.

(1)PV/SV display (Red) : Indicates the process value (PV) and setting value (SV). (2)MEMO/STEP display (Green) : Indicates the memory number during fixed value control. Indicates step number during program control. (3)PV indicator (Red) : Lights up when the input value is indicated. (4)SV indicator (Green) : Lights up when main setting value is indicated. (5)AT indicator (Yellow) : Flashes during auto-tuning (AT). (6)T/R indicator (Yellow) : Flashes during serial communication (Lit while sending data, Unlit while receiving data). (7)OUT indicator (Green) : Lights up when control output or OUT1 (heating side) output (optional: heating / cooling control) is ON.For DC current output type, it flashes corresponding to the manipulated variable in a 0.25 second cycle. (8)EV1 indicator (Red) : Lights up when alarm output 1 or OUT2 (cooling side) output (optional: heating / cooling control) is ON. (9)EV2 indicator (Red) : Lights up when alarm output 2 is ON. (10)Increase key : Increases the numeric value. (11)Decrease key : Decreases the numeric value. (12)Mode key : Selects the setting mode or registers the setting value. (13)OUT/OFF key : The control output OUT / OFF or program control RUN / STOP can be switched.

Notes on site selection

This controller is intended to be used in the following environment (IEC 61010-1)

Mount the controller in a place with:

- Overvoltage category II and Pollution degree 2

- A minimum of dust, and an absence of corrosive gases

- No flammable, explosive gases

- Few mechanical vibrations or shocks

- No exposure to direct sunlight, an ambient temperature of -10 to 55 ℃ 14 to 131 ℉ that does not change rapidly. (When installing inside a panel, make particular allowance for heat dissipation. Avoid installation in situations such as above equipment that generates heat.)

- Locations in which temperature rapidly changes may cause condensation.

- Locations or atmospheres in which benzine, thinners, alcohol, or other organic solvents are present, or in which ammonia, sodium hydroxide, or other strong alkaline substances may adhere.

- Locations susceptible to direct impact or the transmission of vibrations, or where splashing with water is possible.

- In the proximity of equipment in which large switching surges occur or near high-voltage cables, high-voltage equipment, power lines, power equipment, ham radio transmitters, or equipment containing these or similar devices.

- An ambient non-condensing humidity of 35 to 85 % RH

- No large capacity electromagnetic switches or cables through which large current is flowing

- No water, oil or chemicals or where the vapors of these substances can come into direct contact with the controller

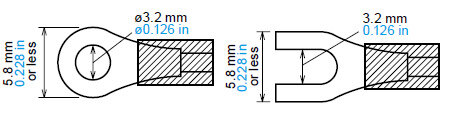

Notes on wiring

| Wire-pressed terminal | Company name | Type name | Fastening torque |

|---|---|---|---|

| Fork type | NICHIFU Co., Ltd. | 1.25Y-3 | 0.6 N•m Max. 1.0 N•m. |

| J.S.T. Mfg. Co., Ltd. | VD1.25-B3A | ||

| Round type | NICHIFU Co., Ltd. | 1.25-3 | |

| J.S.T. Mfg. Co., Ltd. | V1.25-3 |

- The terminal block of KT4R / KT8R / KT9R / KT4H / KT4B series are designed to be wired from the left side (The terminal of KT2 series are designed to be wired from the upper and lower direction). The lead wire must be inserted from the left side of the terminal, and fastened by the terminal screw. Use a wirepressed terminal with insulation sleeve that fits to the M3 screw.

- Terminal screw fastening torque is 0.6 N·m to 1.0 N·m (for KT4R / KT8R / KT9R / KT4H / KT4B series). For KT7 series by M3 screw is less than 0.5 N·m and by M2 screw is less than 0.25 N·m respectively.

- Use a thermocouple and compensating lead wire according to the sensor input specification of the controller.

- Use a 3-wire system of RTD according to the sensor input specification of the controller.

- This controller has no built-in power switch, circuit breaker and fuse. Therefore, it is necessary to install them in the circuit near the external controller. (Recommended fuse: Time-lag fuse, rating voltage 250 V AC, rating current 2 A)

- In the case of 24 V AC / DC power supply, do not confuse the polarity when it is DC.

- With the relay contact output type, use the relay externally according to the capacity of the load to protect the built-in relay contact.

- When wiring, keep input wire (Thermocouple, RTD, etc.) away from power source wire and load wire.

- Turn the power supply to the instrument off before wiring or checking. Working or touching the terminal with the power switched on may result in electric shock which could cause severe injury or death.

- Do not drop wire chips into the holes of vent when wiring.

- To prevent the controller from harmful effects of unexpected high level noise, it is recommended that a surge absorber be installed between the electromagnetic switch coils.

Notes on mounting

- Do not use excessive force while screwing in the mounting frame and mounting bracket of KT4R / KT8R / KT9R / KT4H / KT4B series.

For KT8R / KT9R series, recommended torque is approximately 0.1 N·m.

For KT4H / KT4B series, recommended torque is approximately 0.05 to 0.06 N·m.

For KT4R series, recommended torque is approximately 0.15 N·m. - When mounting the KT7 series to the DIN rail, mount it in a lateral direction. Make sure a click is audible when fixed into place.