CO2 Laser Marker LP-RH

Download

-

Basic Information

-

Applications

-

Option

-

Specifications

-

Dimensions

-

Cautions For Use

------------------------------ Tab1 showing ------------------------------

Basic Information

Improved Speed and Precision!

GB:Conforming to GB 7247.1

Features

Improved speed and precision

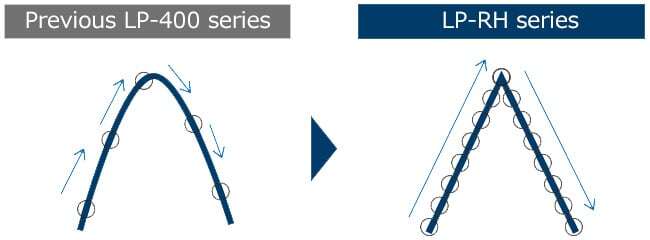

High-speed vector processing engine (VPE)

The dedicated engine (VPE*) for the generation of vector data for marking and processing achieves high-speed marking. The resolution of positioning data for laser scan control has been increased fourfold and the communication speed for galvano mirror positioning control has also been made four times faster. The new engine realizes quicker and more precise engraving as compared to our previous models (LP-400 series).

*Vector Processing Engine

Resolution of instruction signals to the galvano improved by four times

Smoother values of coordinates for interpolation of lines

○: Coordinate instruction value

Two-dimensional code Raster setting reduces takt times by about 40%* with no change in marking quality.

* When compared to previous LP-400 series

The raster marking setting optimizes the two-dimensional barcode engraving sequence to realize faster and higher-quality marking.

(Marking condition) Overall size: 7.2 × 7.2 mm, number of cells: 22 × 22, cell size: 0.30 × 0.30 mm

(Marking condition) Overall size: 7.2 × 7.2 mm, number of cells: 22 × 22, cell size: 0.30 × 0.30 mm

Startup time reduced by about 80%*

The time from the startup of the laser marker system to the startup of laser oscillation is reduced by about 80% as compared to our previous model (LP-400 series). The shorter startup time significantly reduces the waiting times at the time of facility startup, at the time of reset from power OFF triggered by safety circuit, etc.

* When compared to previous model (LP-400 series)

■ Comparison of system startup time and laser excitation time

| Previous LP-400 series | LP-RH series | |

|---|---|---|

| System startup time | Approx. 75 sec. | Approx. 10 sec. |

| Laser excitation time | Approx. 15 sec. | Approx. 5 sec. |

Significant reduction of system startup time and laser excitation time

Simplifies facility designs

Head rotating mechanism [Standard models (horizontal type)]

The head is structured to allow flexible angle setting in a range of 350 degrees. The head angle can be rotated according to the marking surface angle to facilitate the installation along the line. This minimizes the installation spaces and eliminates the need for complex jig design. Simple jigs can be employed even when marking in the upward direction or at an oblique angle.

![Head rotating mechanism [Standard models (horizontal type)]](https://tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/lasermarker/lasermarker/lp-rh/images/pic05.jpg)

* Multiple units set up in different directions are shown in each of the above illustrations for the explanatory purpose.

Installation footprint: Smaller than a B5 sheet of paper [Tower head models (vertical type)]

The head measures 230 mm x 175 mm 9.055 in x 6.890 in and is smaller than B5 size. The LP-RH series can be installed easily in existing lines, without worrying about a lack of space. The new series also allows for compact equipment designs, so it significantly reduces the required installation space and helps cut the cost of facilities such as line machines and floor lighting systems.

![Installation footprint: Smaller than a B5 sheet of paper [Tower head models (vertical type)]](https://tp.industry.panasonic.com/hubfs/pid-corp/products/fasys/lasermarker/lasermarker/lp-rh/images/pic06.jpg)

Interchangeable with previous Panasonic Industry head

The installation dimensions and mounting hole size/layout of the LP-RH series are the same as those of the previous head (LP-400 series).

Furthermore, marking data and communication commands are also interchangeable.

* Marking quality, operation, etc., must be checked in advance.

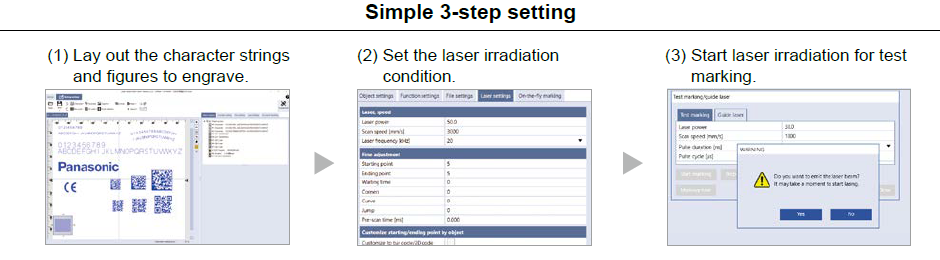

Laser Marker NAVI smart

The software allows for easy marking setting and easy maintenance. It reduces the man-hours required for installation and operation.

------------------------------ Tab2 showing ------------------------------

Applications

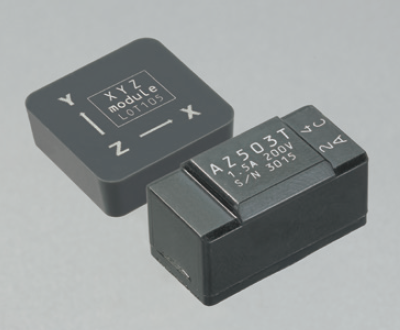

Marking

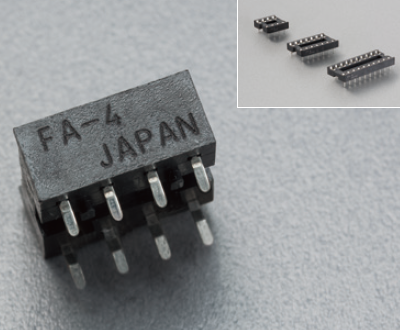

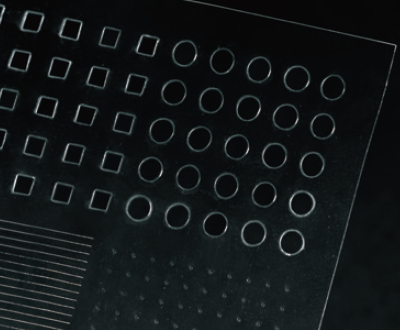

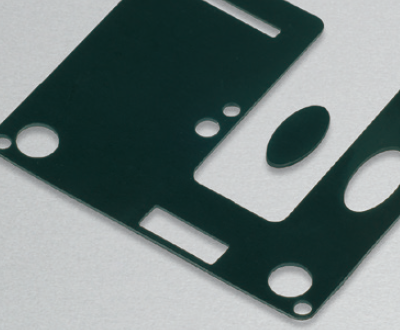

Molded resin parts

Electronic parts

Connectors

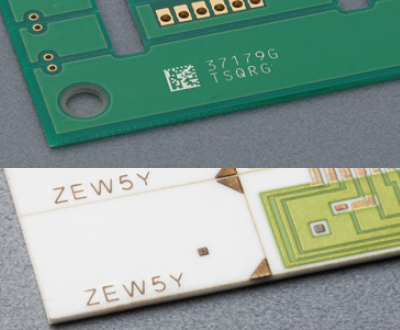

Ceramic substrates

Circuit boards

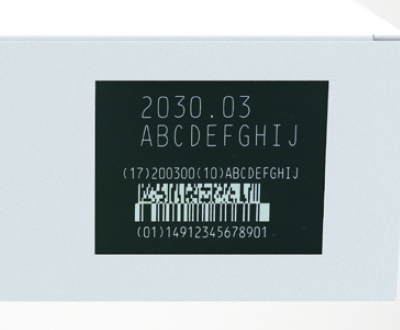

Retort pouches

Products packaging

Aluminum packaging materials

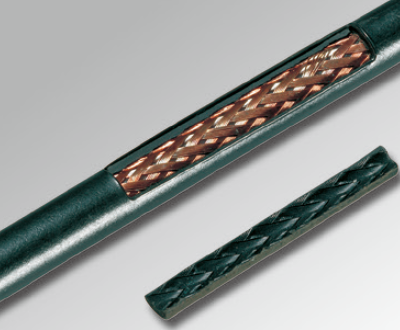

Processing

------------------------------ Tab3 showing ------------------------------

Option

Industrial network unit

| Type | Model No. |

|---|---|

| Industrial network unit for EtherNet/IP | LP-ANW10 |

| Industrial network unit for PROFINET | LP-ANW11 |

* EtherNet/IP is a registered trademark of ODVA (Open DeviceNet Vender Association, Inc.).

* PROFINET is a registered trademark of PROFIBUS & PROFINET INTERNATIONAL.

AC power cable

Use the cable that complies with the regulations and standards of the country / region where the product is used.

| Type | Model No. | ||

|---|---|---|---|

| AC power cable | Rating 125 V AC | PSE standards compatible cable (Japan) | LP-ACA10 |

| Rating 250 V AC | PSE standards compatible cable (Japan) | LP-ACA11 | |

| CE marking compatible cable (Europe) (Note 1) | LP-ACA12 | ||

Note: 1) The plug of the 250 V AC, CE-compliant cable (for Europe) conforms to the following standards.

VDE, DEMKO, NEMKO, FIMKO, SEMKO, OVE, KEMA, CEBEC

Touch panel console / Expansion board

Note: 2) When the expansion board is installed to the controller, the following functions can be used.

• Connect a touch panel console or a commercially available monitor to the laser marker and use it for monitoring and setting during operation.

• The displacement sensor is connected to the laser marker to correct the work distance.

Maintenance and service parts

| Type | Model No. | |

|---|---|---|

| Controller air filter (replacement part) | Set of 2 fans (Urethane type) | LP-AFT92 |

| Head air filter (replacement part) | Set of 2 fans (Urethane type) | LP-AFT93 |

| Cooling fans of controller (for replacement) | Set of 2 units | LP-AFA20 |

| Unit power cable (for replacement) | 5 m 16.404 ft type | LP-ACP20-5 |

| Signal cable (for replacement) | 5 m 16.404 ft type | LP-ACS10-5 |

| Contactor unit for Interlock (for replacement) | LP-AEC10 | |

------------------------------ Tab4 showing ------------------------------

Specifications

Optical specifications / scanning specification

| Model No. | Standard model (horizontal type) | LP-RH300S | LP-RH200S | LP-RH100S | LP-RH301S | LP-RH101S | LP-RH305S |

| Tower head model (vertical type) | LP-RH300T | LP-RH200T | LP-RH100T | LP-RH301T | LP-RH101T | LP-RH305T | |

| Scanning system | Galvano scanning method | ||||||

| Marking field (X, Y) | 110 mm × 110 mm 4.331 in × 4.331 in | 55 mm × 55 mm 2.165 in × 2.165 in | 160 mm × 160 mm 6.299 in × 6.299 in | ||||

| Work distance (Note 1) | 185 mm 7.283 in | 111 mm 4.370 in | 262 mm 10.315 in | ||||

| Scan speed (Note 2) (Note 3) | 12,000 mm/sec. max. 472.441 in/sec. max. | 6,000 mm/sec. max. 236.22 in/sec. max. | 12,000 mm/sec. max. 472.441 in/sec. max. | ||||

| Applicable line speed (Note 2) | 240 m/min max. 787.402 ft/min max. | 120 m/min max. 393.701 ft/min max. | 240 m/min max. 787.402 ft/min max. | ||||

| Character height / width (Note 2) | 0.100 mm to 110.000 mm 0.004 in to 4.331 in | 0.100 mm to 55.000 mm 0.004 in to 2.165 in | 0.100 mm to 160.000 mm 0.004 in to 6.299 in | ||||

Laser specifications / Other basic specifications

| Model No. | Standard model (horizontal type) | LP-RH300S | LP-RH200S | LP-RH100S | LP-RH301S | LP-RH101S | LP-RH305S |

| Tower head model (vertical type) | LP-RH300T | LP-RH200T | LP-RH100T | LP-RH301T | LP-RH101T | LP-RH305T | |

| Applicable regulations and certifications | FDA Regulations, CE Marking [Machinery Directive (Declaration of Incorporation), EMC Directive, RoHS Directive], UKCA Marking [Supply of Machinery (Safety) Regulations (Declaration of Incorporation), EMC Regulations, RoHS Regulations], UL/c-UL Recognition, Chinese Standard GB 7247.1 | ||||||

| Marking laser | Marking laser | CO2 laser, Class 4 laser | |||||

| Wavelength | 10.6 μm 0.417 mil | 9.3 μm 0.366 mil | 10.6 μm 0.417 mil | ||||

| Oscillator average output | 30 W | 20 W | 10 W | 30 W | 10 W | 30 W | |

| Average output for marking (Note 4) | 30 W | 18.2 W | 10 W | 30 W | 10 W | 30 W | |

| Laser oscillation system | CW oscillator | ||||||

| Guide laser, laser pointer | Red semiconductor, Wavelength: 655 nm 0.0258 mil, Class 2 laser, Maximum output: 1 mW or less | ||||||

| Beam stop | One shutter is equipped inside of head | ||||||

| Workpiece status | Stationary object, Moving object | ||||||

| No. of registerable files | 10,000 files | ||||||

| No. of marking data pieces (No. of registerable objects) | 2,000 objects/file | ||||||

| Marking data | Character | West-European alphabet (A to Z, a to z, Latin-1 characters), numeric, symbol, user defined characters (up to 50 characters can be set) Japanese characters: Katakana, Hiragana, Kanji (JIS level-1 and level-2) Simplified Chinese characters: GB 2312 level-1 and level-2 | |||||

| TrueType | TrueType fonts stored in the PC with Laser Marker NAVI smart installed (Note 5) | ||||||

| Bar code | CODE39, CODE128, ITF, NW-7, JAN/UPC GS1 DataBar (GS1 DataBar Limited, GS1 DataBar Stacked, GS1 DataBar Expanded, etc.), GS1 Composite Code (GS1 DataBar Limited CC-A, GS1 DataBar Stacked CC-A, GS1-128 CC-A, etc.) | ||||||

| 2D code | QR code, Micro QR code, iQR code, Data Matrix, GS1 Data Matrix, PDF417 | ||||||

| Graphic file (Note 6) | VEC, DXF, HPGL, BMP, JPEG, AI, EPS | ||||||

| Point and shapes | Point radiation, line, circle, arc | ||||||

| Character arrangement | Straight line, Arc, Proportional, Justify | ||||||

| I/O port | I/O terminal block (40-pins), I/O connector (40-pins) | ||||||

| Communication interface | EIA-RS-232C, Ethernet, EtherNet/IP (Note 7), PROFINET (Note 7) | ||||||

| Dedicated software (Note 8) | Laser Marker NAVI smart, Logo Data Editing Software, ExportVEC, Font Maker | ||||||

| Supported OS (Note 9) | Windows® 11 Pro 64bit, Windows® 10 Pro 32bit / 64bit | ||||||

| Laser marker NAVI smart connection method | USB, Ethernet | ||||||

| Laser marker NAVI smart display language | Japanese, English, Simplified Chinese, Traditional Chinese, German, Korean | ||||||

| Required time for system startup | Approx. 10 seconds | ||||||

| Required time for laser excitation | Approx. 5 to 10 second max. | ||||||

| Power voltage | 90 V to 132 V AC or 180 V to 264 V AC (including ±10% voltage fluctuations), Frequency: 50/60 Hz (Note 10) | ||||||

| Power consumption (Consumption current) (Note 11) | At 100 V AC | 760 VA or less (8.5 A or less) | 370 VA or less (4.1 A or less) | 760 VA or less (8.5 A or less) | 370 VA or less (4.1 A or less) | 760 VA or less (8.5 A or less) | |

| At 200 V AC | 720 VA or less (4.0 A or less) | 430 VA or less (2.4 A or less) | 720 VA or less (4.0 A or less) | 430 VA or less (2.4 A or less) | 720 VA or less (4.0 A or less) | ||

| Grounding method | Direct earth for the head and controller respectively | ||||||

| Cooling method | Head: Forced air-cooling, Controller: Forced air-cooling | ||||||

| Operating ambient temperature (Note 12, 13) | 0 ℃ to +40 ℃ +32 ℉ to +104 ℉, Storage: -10 ℃ to +60 ℃ +14 ℉ to +140 ℉ | ||||||

| Operating ambient humidity (Note 12) | 35 to 85% RH | ||||||

| Overvoltage category / Pollution degree | Ⅱ / 2 | ||||||

| Use location | Indoor; at an altitude of 1,000 m 3280.840 ft or below | ||||||

| Installation direction | Head: In all directions, Controller in assembled condition: Vertically or horizontally | ||||||

| Weight | Head | Approx. 19 kg | Approx. 17 kg | Approx. 19 kg | Approx. 17 kg | Approx. 19 kg | |

| Controller | Approx. 12 kg | ||||||

| Battery (mounted in product) | Graphite fluoride-lithium primary battery, AFPX-8801 (BR-2/3A): 1 pc., Weight: Approx. 14 g | ||||||

Notes:

1) There is some degree of variation between individual units of the same model.

2) The value shown here is the configuration range that can be input. The setting values that can keep the quality of marking or processing vary depending on the setting details and the target materials.

3) Depending on the setting data, the available scan speed might be limited.

4) Output at processing point when power is set to max. (default setting).

5) Some of the languages or character types are not supported by this laser marker.

Characters written from right to left such as Arabic or Hebrew, characters based on ligature such as Indian languages cannot be input.

6) VEC is a graphic file format dedicated for the laser marker. To use AI or EPS files, convert them to VEC format with the dedicated software “ExportVEC”.

7) Available when the optional network unit is installed to the controller.

8) The software is available from our Internet website.

9) OS versions of which Microsoft has ended support are excluded.

10) The frequency switches automatically.

11) The typical value of the inrush current at startup is as follows: (Duration time is 10 ms or less.)

At 100 V AC: 90 A, At 200 V AC: 180 A

12) Common to the controller and head. No condensation or freezing shall be allowed. If there is a gap between the stored temperature and operating temperature, make sure to have the product get used to the operating ambient temperature gradually prior to use to prevent the dew condensation.

13) Laser output may vary due to ambient temperature fluctuations.

* QR Code is a registered trademark of DENSO WAVE INCORPORATED.

* EtherNet/IP is a registered trademark of ODVA (Open DeviceNet Vender Association, Inc.).

* PROFINET is a registered trademark of PROFIBUS & PROFINET INTERNATIONAL.

* Windows is a registered trademark or trademark of Microsoft Corporation in the United States and/or other countries

------------------------------ Tab5 showing ------------------------------

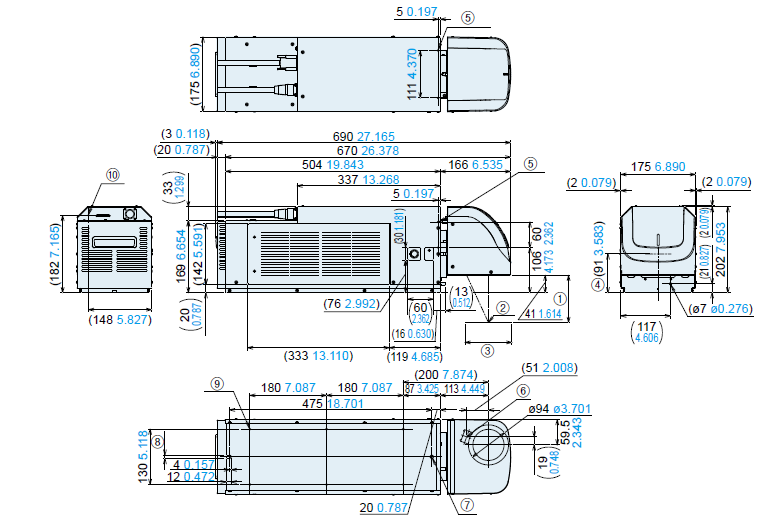

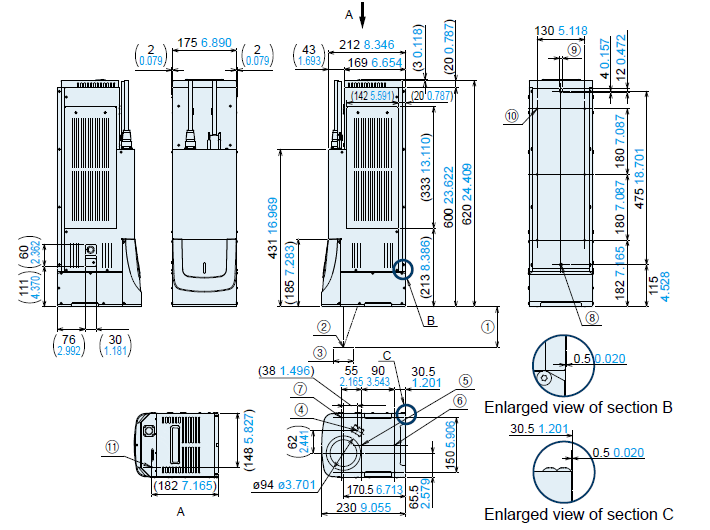

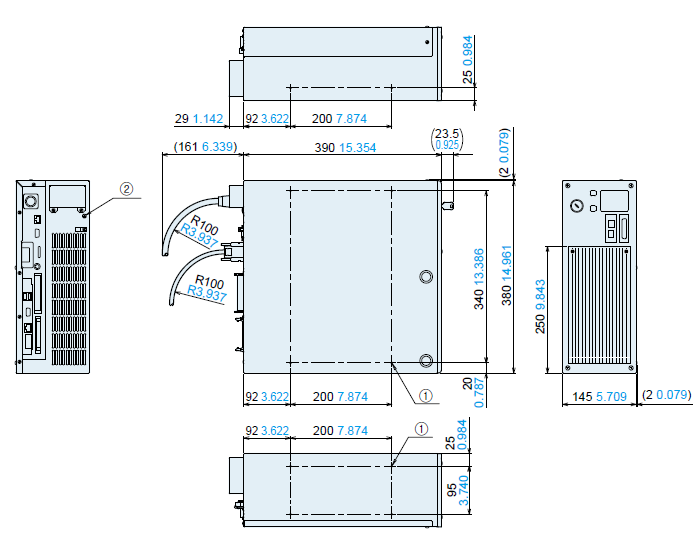

Dimensions

- Unit: mm in

Head: Standard model (horizontal type)

| No. | Description |

|---|---|

| ① | Work distance: |

| ② | Center of marking field |

| ③ | Marking field (X, Y): LP-RH300S / LP-RH200S / LP-RH100S:110 mm × 110 mm 4.331 in × 4.331 in |

| ④ | Center of scanner section rotation |

| ⑤ | Screw hole for fixing protective enclosure and others (2 locations each on top surface and two side surfaces): M4 screws, depth 10 0.394 |

| ⑥ | Laser pointer emission port ø19 mm ø0.748 in |

| ⑦ | Head positioning pin hole: ø8 ø0.315+0.010 , depth 4 0.157 |

| ⑧ | Head positioning pin hole: Elongated hole ø8 ø0.315+0.010 × 12, depth 4 0.157 |

| ⑨ | Head fixing screw hole (six holes): M6 screw, depth 15 0.591 |

| ⑩ | Screw for frame ground: M4 screw, depth 5 0.197 |

Head: Tower head model (vertical type)

| No. | Description |

|---|---|

| ① | Work distance: |

| ② | Center of marking field |

| ③ | Marking field (X, Y): LP-RH300T / LP-RH200T / LP-RH100T:110 mm × 110 mm 4.331 in × 4.331 in |

| ④ | Laser pointer emission port ø19 mm ø0.748 in |

| ⑤ | Lens-side head positioning pin hole:ø4 ø0.157+0.06+0.02 , depth 6.5 0.256 |

| ⑥ | Lens-side head positioning pin hole: Elongated hole ø4 ø0.157+0.06+0.02 ×5, depth 6.5 0.256 |

| ⑦ | Lens-side head fixing screw hole (6 locations): M6 screws, depth 7 0.276 |

| ⑧ | Rear-side head positioning pin hole: ø8 ø0.315+0.010 , depth 4 0.157 |

| ⑨ | Rear-side head positioning pin hole: Elongated hole ø8 ø0.315+0.010 × 12, depth 4 0.157 |

| ⑩ | Rear-side head fixing screw hole (6 locations): M6 screws, depth 15 0.591 |

| ⑪ | Screw for frame ground: M4 screw, depth 5 0.197 |

Controller

①Controller fixing screw hole (4 locations each on bottom surface and left side as viewed from front side): M5 screws, depth 6 0.236

②Screw for protective conductor terminal: M4 screw, threaded section length 5 0.197

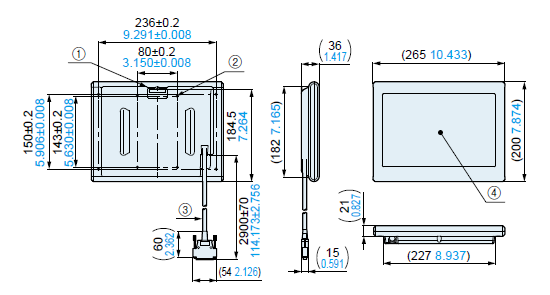

Touch panel console (Optional)

①Wall hanging hook hole: Hole size 33 mm × 5 mm 1.299 in × 0.197 in, hook section radius 3 mm 0.118 in

②Fixing nut (8 locations): M4 screw, depth 5 mm 0.197 in, tightening torque 0.7±0.1 N∙m

Fixing locations: 4 locations on inside surface or 4 locations on outside surface

③Connection cable: Minimum bending radius 65 mm 2.559 in, cable diameter ø8.6 mm ø0.339 in

④Touch panel: Display area 216 mm × 135 mm 8.504 in × 5.315 in

------------------------------ Tab6 showing ------------------------------

Cautions For Use

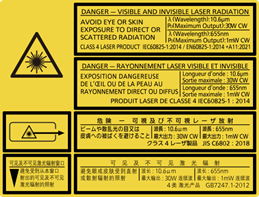

About laser light

- This product is a Class 4 laser product as defined by the JIS standards. Do not look directly toward the laser light or touch the laser light or its reflections. Be sure to take the required safety measures in accordance with the standards.

- The labels shown at the right are affixed on the product. (The labels are not affixed on the products shown in this website.)

- The laser light is an infrared light and invisible to the human eyes. Exercise caution when the laser oscillator is operating.

Warning, explanation, aperture labels

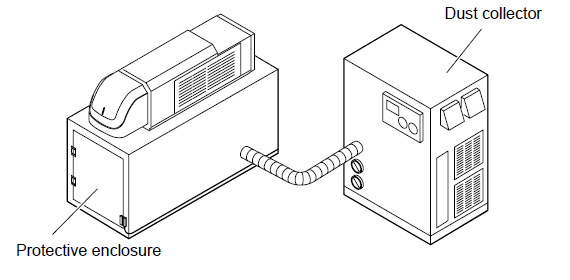

Use of dust collector recommended

- Some materials generate a toxic gas or smoke during laser marking, and this may cause adverse effects on the human health or laser marker. In such a case, use a dust collector. For more information, please contact our sales representative.