Reduce waste. Cut implementation costs.

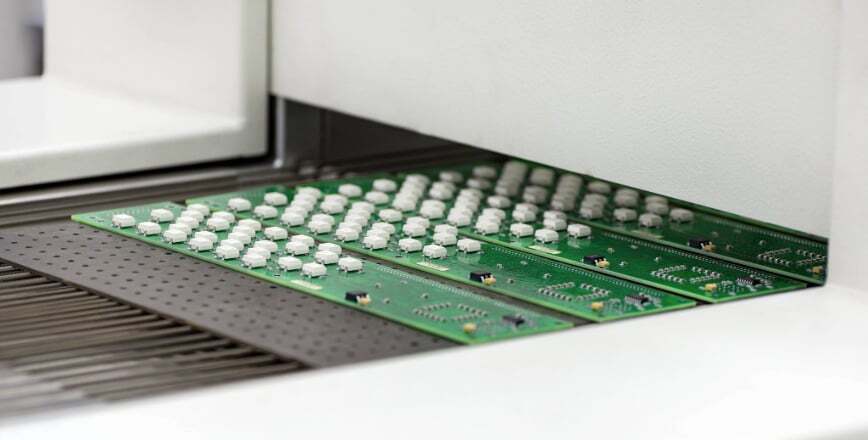

Streamline your workflow. Cut outsourcing costs with reflow implementation.

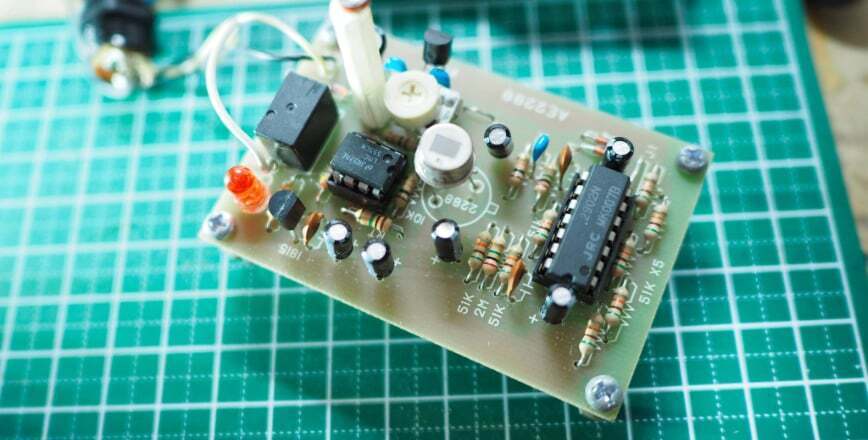

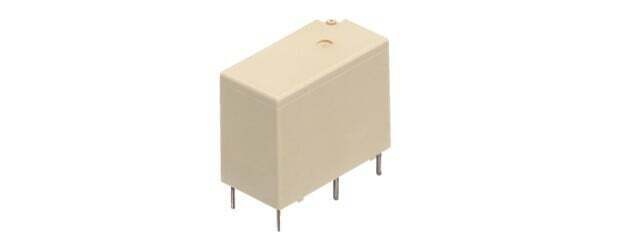

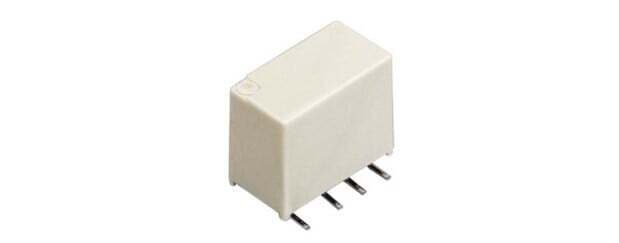

Compact design. Handles up to 10 A (12 A for carry current). Compatible with standard LQ relay footprint.

Quickly compare key specs.

Download our summary sheet to get started.

As production environments evolve, selecting power relays based solely on specifications is no longer enough. Mounting compatibility is becoming a critical factor.

By adopting reflow-compatible relays, manufacturers can centralize their soldering processes—leading to improved substrate productivity and streamlined operations.

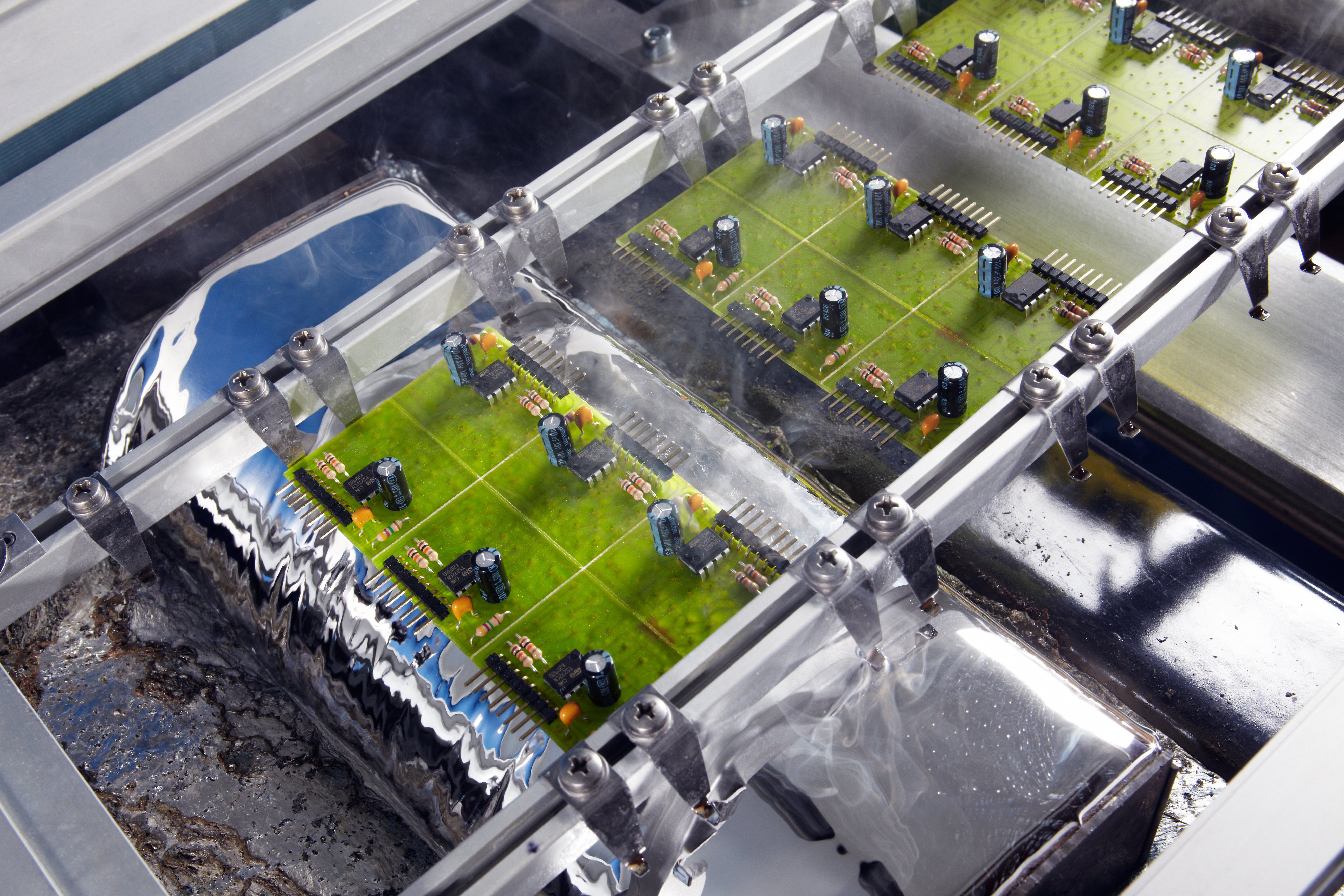

Traditionally, power relays are mounted using flow soldering, which often requires additional labor and cost. In-house setups demand expensive jigs, while outsourcing increases both time and expenses.

Panasonic’s LQ relay reflow-compatible type offers a compact design, supports high current, and fits seamlessly into reflow soldering processes.

With the same terminal layout as the standard LQ relay, it enables easy replacement—allowing you to solve mounting challenges without changing your existing process.

Just starting your search? Start here.

All the key specs and highlights—ready for quick review and download.

The LQ relay unlocks new flexibility in both design and production—going beyond traditional constraints.

Its compact size and high current capacity are just the beginning.

Reflow compatibility adds process design freedom, delivering real benefits across FA equipment, air conditioning control, and power supply applications.

reduction

No need for jigs, setup changes, or outsourcing—streamlining the entire mounting process.

Labor costs are reduced by approximately 80%, based on our comparison with conventional operator counts and per-component labor costs.

This enables flexible response to low-volume, high-mix production.

Just starting your search? Start here.

Company;

Mitsubishi Electric Corporation

Development Background

Conventional relays required flow soldering, which led to challenges such as line division, setup changes, and outsourcing.

To address these issues, the LQ Relay was developed to support reflow soldering, significantly reducing process complexity.

Customer Feedback

“We improved board production efficiency simply by switching to the LQ Relay.”

The new relay greatly enhanced the substrate mounting process and helped us meet the demands of overseas markets.

As a result, our system received high praise from customers.

Just starting your search? Start here.

When considering the LQ Relay, Panasonic Industry offers technical support throughout every stage—from early development to full-scale production.

Our deep expertise as an electronic component manufacturer, combined with a strong focus on real-world challenges,

ensures reliable support for both design and procurement teams.

Provision of environmental performance and reliability data.

Indicate design considerations when transitioning from flow to reflow.

Support for product analysis after actual machine evaluation.

Response to customer requests for evaluation.

Compliance with overseas safety standards (UL, VDE, etc.).

Smooth support for evaluation and procurement at overseas bases.

This section provides answers to frequently asked questions from customers.

What is the difference between the standard versus reflow soldering types of the LQ Relay?

The external dimensions and ratings are nearly identical, however the reflow soldering type is optimized for heat resistance which can support reflow soldering.

The footprint is also compatible, allowing existing board designs to be migrated smoothly without changing the PCB layout.

Can the reflow type be mounted using flow soldering?

The reflow type is designed primarily for reflow soldering, however flow (wave) soldering may be possible under certain conditions. Please contact us for specific implementation requirements.

Are there any recommended conditions or temperature profile for the reflow soldering procedure?

Yes, we provide technical documentation that includes recommended reflow soldering profiles. We can offer guidance of the optimal conditions based on your temperature settings and the material of the mounting substrate.

Can I use it for overseas products?

Yes, the LQ Relay complies with major international standards such as UL and VDE which makes it suitable for use in global markets. Procurement and technical support are also available locally through our overseas sales offices.

Is it possible to provide samples or obtain reliability data?

Yes, we will respond individually based on the application and required data. Evaluation samples and test data will be provided promptly and can be tailored to the customer’s design stage accordingly.

Just starting your search? Start here.

LQ relay

Small, high-current (10 A, only for carrying current 12 A) relay. Corresponds to rush prevention short-circuit resistance applications in the home appliance and industrial equipment markets.

DW relay

In addition to its compact size and low power consumption design, this 16 A poled latching relay has excellent collision-resistant current performance. Supports a wide range of applications with both high reliability and energy saving.

SF-M relay

Small and low-profile safety relay with forced guide contact structure conforming to safety standards. Low power consumption type contributes to energy saving design.

GN relay

2c contact with high sensitivity (rated operating power 100 mW) 1 A compact, slim relay for signal

GQ relay

2c contact with high sensitivity (rated operating power 100 mW) 2 A compact flat relay for signal

TX relay

Signal relays with variations such as TX-D relay with surge withstand voltage of 6000 V and TX-TH relay with inrush current of 7.5 A

TQ relay

Flat shaped compact signal relay controllable up to 2 A 30VDC contact capacity

PhotoMOS relay(Solid-state relay)

A compact, contactless, and long-life semiconductor relay that uses a MOSFET for its output. Features low on-resistance and fast response.

Tactile Switches (Light Touch Switches)

Compact and thin momentary type micro current switch. Variations in stroke and operation feel.

Quickly compare key specs.

Download our summary sheet to get started.

Contact

Please feel free to contact us.

We’d love to hear about any challenges you’re facing in the field—whether it’s improving mounting efficiency with reflow soldering or replacing small, high-capacity relays.

We offer tailored proposals based on your design and manufacturing environment, including consultations on detailed specifications and mounting conditions for LQ relays, as well as support for replacing existing components.

Individual technical support is also available.

Recommended for:

Panasonic Industry Co., Ltd.

Copyright © Panasonic Industry Co., Ltd.